FPInnovations develops production process for cellulose filaments

March 22, 2016

By FPInnovations

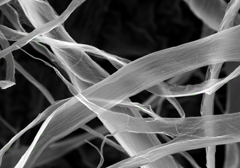

March 22, 2016 - FPInnovations has developed a unique process for the production of cellulose filaments from natural pulp fibres. The process involves mechanical peeling, does not require the use of chemicals or enzymes, and does not produce effluents, making it environmentally friendly and well-suited for the Canadian forest industry. Cellulose filaments obtained by this process have unique features, including sub-micron widths, very high aspect ratios, high flexibility, high surface area, and high bonding potential. They have been shown to be excellent strengthening agents, bringing significant improvement in the wet-web and dry strength of tissue, towel, printing and writing, and specialty paper grades. Applications in composite and other non-paper products are also being explored.

In order to achieve their full reinforcement potential, the filaments must be well dispersed. Indeed, it was found that because of their nature, the filaments tend to stick together and therefore lose their full strengthening potential. Work was conducted by FPInnovations at the laboratory and pilot plant scale to develop methods to efficiently disperse never-dried cellulose filaments, as well as monitor the quality of the filaments in the dispersions. These methods have now become current practice in research laboratories and commercial plants working with cellulose filaments.

The next challenge was to provide methods that would allow drying of the cellulose filaments to decrease shipping costs and extend the shelf life of the product. In one approach, techniques were developed to produce films from which the dry cellulose filaments can be effectively re-dispersed in water and retain their original strengthening properties. Another approach involves the incorporation of the filaments into a carrier pulp, followed by drying of the wet mixture using conventional drying equipment. It was found that high percentages of addition can be reached with carrier pulp and that, with proper patented treatment, the filaments can be easily re-dispersed in water and maintain their unique reinforcement potential. Patent applications have been filed for these processes.

The development of cost-effective processes for the production of dry and fully re-dispersible products opens the door for cellulose filaments to move from traditional pulp and paper markets to innovative applications in many other industrial sectors. For more information concerning cellulose filaments, please contact Yuxia Ben at (514) 782-4602.

Print this page