Biomass boiler showcase

October 2, 2015

By Staff report

October 7, 2015 - The latest technologies and innovations in biomass boiler technology.

Biomass Combustion System

Biomass Combustion System

The BCS 300 HP, hot water, wood boiler from Biomass Combustion System features the company’s horizontal zoned grate combustion system, which strictly regulates under fire air for gasification with low bed turbulence. The boiler burns dry sawdust and chips from the facility to heat dry kilns, but green wood fuel can be burned efficiently with adjustments to air and fuel delivery. The boiler is rated for 10 million BTU output and can maintain a 10 to 1 turndown ratio on dry fuel so it can operate at one million BTU/hr without losing the fire.

Hurst Boilers

Hurst Boilers

Hurst Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete solid fuel boiler systems, from the fuel storage system through to exhaust gas emission mitigation.

Various boiler designs are suitable for applications to produce high-pressure steam or hot water in ranges from 3,450 to 60,000 lbs/hr (3.4 mmBTU to 60 mmBTU) output from 100 to 900 psi. Hurst systems are capable of burning material with 0 to 50 per cent moisture content. The systems also feature an automatic ash removal system, high temperature cast refractory ceramic lining and PLC controls.

Viessmann

Viessmann

Viessmann’s Pyrotec fully-automatic underfeed combustion wood-fired boiler is available in five models with inputs raining from 1,330 to 4,268 MBH. It is designed for wood fuels with maximum water content of 50 per cent. The combustion chamber is lined with compressed firebricks with high alumina content for added durability. All grate elements are made of durable cast chrome steel. The boiler is built with a classic triple-pass heat exchanger design for maximum heat transfer and efficiency and a modulating output control with a 4:1 turndown ratio. It is available with a maximum operating pressure of 30 or 60 psig.

Andritz

Andritz

Andritz state-of-the-art bubbling fluidized bed (BFB) boilers are fuelled by woody biomass with 40 to 60 per cent fuel moisture. They offer a heating value range of 5.5 to 10.1 MJ/kg and have a fuel consumption of 100 t/h. The boilers convert woody biomass into superheated steam with a capacity of 295 t/h steam, a steam temperature of 524°C and a feed water temperature 232°C.

Woodmaster

Woodmaster

WoodMaster Commercial Series boilers feature automatic fuel feeding with wood pellets or wood chips, and ash extraction and soot blowing to reduce maintenance. They are designed to achieve 92% LHV efficiency and are available in 14 models ranging from 45kW to 2,000kW. The units have ASME and CRN certified pressure vessels and have CSA certification. The boilers are built with a 10.4” touchscreen PLC/HMI full colour control panel with remote access. Custom options are also available. Boilers are built in the U.S.

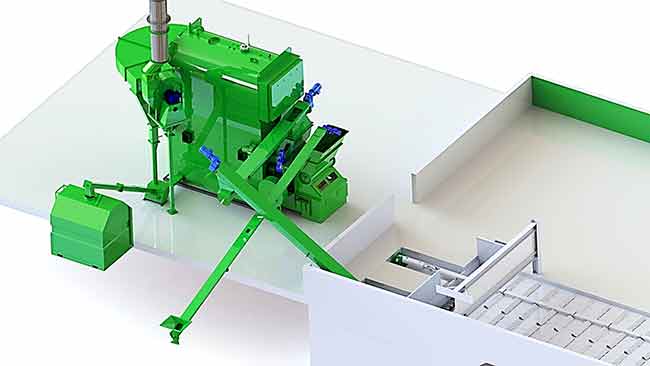

Transfab Énergie

Transfab Énergie

Transfab Énergie designs and fabricates ASME certified custom biomass-fired energy systems from 200 Kw to 10,000 Kw to meet the needs and requirements of its customers. We are especially proud of our successes in efficiently burning wood bark with high moisture content such as the 6,000 Kw high-pressure steam assembly shown here. All components were designed and fabricated at our plant.

Boilersmith

Boilersmith

Boilersmith Ltd. is a manufacturer of premium, Canadian manufactured, firetube, firebox style hot water, low-pressure steam and high pressure steam boilers, that are suitable for a variety of biomass-fired combustion systems. Other boiler design types are also available, and all are customized to match our customer’s requirements. In this way, maximum flexibility can be obtained in combustion system selection for a variety of biomass fuel types and moisture content. A large selection of boiler sizes is available, ranging from 500 kW to more than 5,000 kW.

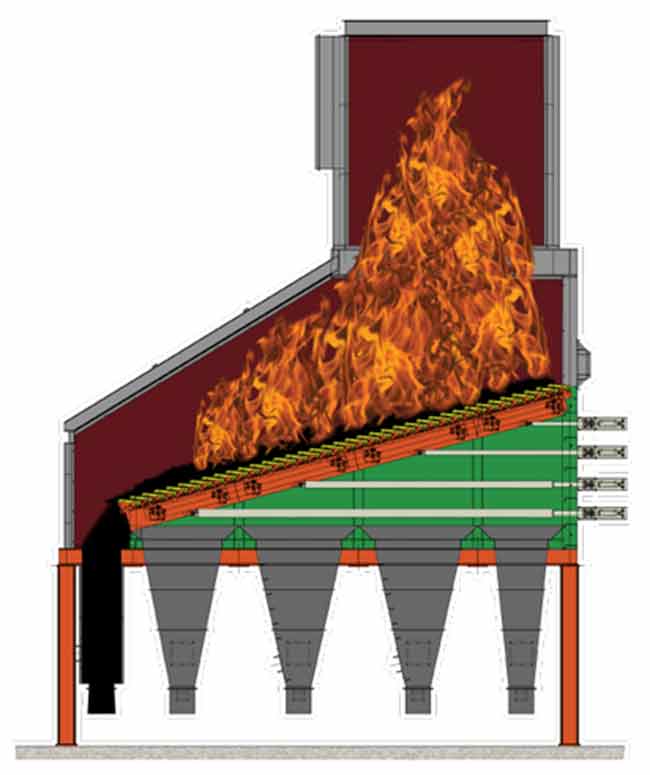

Detroit Stoker

Detroit Stoker

Detroit Stoker Company’s GTS Reciprocating Biomass Stoker features inclined reciprocating grates that push the fuel down the length of the grate through distinct drying, gasification, combustion and burn-out zones. The grates are high alloy material so air cooling is sufficient. The ash is automatically discharged off the end of the grate into an ash conveying system. The reciprocating grate handles a wide range of feed materials including wood chips, bark, sawdust, forest waste and agricultural waste. It handles low heat value fuels and offers conservative sizing for assured capacity and low emissions.

KMW

KMW

KMW supplies complete biomass systems for the production of hot water, hot oil, low pressure and high-pressure steam for power generation. Boilers range in size from 100 HP to 3500 HP and complete power plants are available in the range of 250 kW to 50 MWe. Construction cost and time are kept to a minimum by shop building and testing all equipment. KMW’s patented grate system provides great fuel flexibility for utilization of low cost fuel including wet bark, mill sludge, bio solids, and MSW.

beloTEQ

beloTEQ

Global Series Uniconfort steel boilers from beloTEQ are built with a refractory coating with high alumina content. They have a refractory steel combustion grill designed for burning solid biomass with high moisture content (up to 150 per cent on a dry basis). They feature a completely dry, large-section combustion chamber with several smoke turns for optimal dust capture in the fumes. The boilers are suitable for the production of heating fluids with maximum pressures of up to 24 bar in the standard version and higher in special versions.

Blue Flame Stoker

Blue Flame Stoker

Biovalco Engineers manufactures and implements biomass heating plants under the trademark Blue Flame Stoker, including hot water biomass boilers (30 psig), fired steam biomass boilers (15 to 150 psig) and direct-fired biomass furnaces. The capacity of the biomass-fired systems ranges from 250 kW to 6,000 kW. They also offer containerized solutions up to 750 kW.

SIM Enterprises

SIM Enterprises

Pyrogenic Industrial Biomass Stokers from SIM Enterprises are multi-fuel combustion systems with high combustion efficiency. The units are equipped with a multi-fuel system for wood pellets, wood chips and agricultural residue; and a multi-fuel feed system. The hot water, low pressure and high-pressure steam boilers are built to ASME code.

Outotec

Outotec

Using biomass and wood-based residue fuels, Outotec solutions can convert industrial waste products, such as bark, pulp and paper rejects, lignin from ethanol production or even agro biomass, into electricity and heat/steam. For residue fuels with a high amount of large inorganic components such as stones, glass and bricks, Outotec fluidized bed technology uses an open nozzle grid design, which allows for a stable combustion process and proper debris removal. Plants using fuels with a high variation in calorific value can be equipped with flue gas recycling and/or combustion air preheating.

Compte Fournier

Compte Fournier

Compte Fournier’s Granul’Eco hot water pellet boilers range from 200 to 1,000 kW (20 to 100 HP) and use wood pellets or agro-pellets as fuel. These boilers are ideal for urban or remote setups where constraints in fuel delivery or availability favour the use of pellets. A fully automated solution, from feeding to lighting up to ash extraction, suiting your energy needs in small-scale collectivities, residential buildings and light industries while respecting tight environmental emissions controls.

Advanced Climate Technologies

Advanced Climate Technologies

Advanced Climate Technologies (ACT) manufactures high-efficiency wood pellet and wood chip boilers for commercial, institutional multi-family residential buildings. The boiler systems range in size from 0.5 to 1.7 million BTUs for buildings sized 5,000 to 100,000 sq. ft. ACT Bioenergy Boilers have been specifically designed to optimize customer convenience and ease-of-use to complement or completely replace conventional fossil fuel boilers systems in buildings.

Valmet

Valmet’s Hybex boilers use bubbling fluidized bed (BFB) combustion technology. They offer wide fuel flexibility, high combustion efficiency, high reliability, excellent controllability and low emissions. They are available sizes ranging from 10 to 400 MW and have a combustion efficiency of over 99 per cent, resulting in boiler efficiency typically around 90 per cent, even with high moisture fuels. It is ideal for all types of wood fibre fuels.

Decker Manufacturing

The pressurized industrial Decker Brand Boiler is designed to heat facilities such as greenhouses, manufacturing plants, livestock facilities and machine shops. It is designed for multi-fuels including wood pellets, oat hull pellets and coal; and comes in six sizes ranging from 500,000 to 3,500,000 BTU. They are upwards of 85% efficient. They feature an automated tube cleaning system for maximum efficiency, an automated ash removal system and are fully insulated.

Indeck

Depending on the fuel(s) fired and the design requirements of the boiler, steam capacities can range from 25,000 to 600,000 lb. steam/hr. Solid fuel fired boilers are available in two drum open pass” and a single drum MSW design.

Print this page