Spotlight on Hammermills

February 23, 2015

By Staff Report

Feb. 23, 2015 - The expansion of the wood pellet industry in Canada has caused hammermill manufacturers to expand their product offerings to the North American market. As a result, there are more options for pellet mill equipment than ever before here in Canada.

Here is a look at the newest in hammermill innovation and technology available for the Canadian wood pellet industry.

Andritz

Andritz

Andritz Series 6 Hammer Mill is now offered in both 38-inch (965 mm) and 43-inch (1,092 mm) diameters with grinding chamber widths ranging from 12-inch (305 mm) to 60 inches (1,524 mm). These mills can accommodate motor sizes ranging from 125 HP (90 kW) to 600 HP (450 kW). This unique Series 6 design was created to satisfy today’s demanding applications and safety guidelines.

Jeffrey Rader

Jeffrey Rader

TerraSource Global’s Jeffrey Rader brand offers a wide range of hammermills including FT and FTE Flextooth Crushers for larger products and Mini-Mill™ E, 30ABE, and 34ABE models for smaller products and sampling. “E” designations in each model signify the brand’s exclusive E-Z Access technology, which allows safe, fast, and easy access to hammers, rotors, and liners. All models are equipped with heavy-duty rotors that can be set up with three, four, or six rows of hammers.

Bruks

Bruks

BRUKS has developed a high efficiency hammermill for biomass and biofuel applications. The hammermill features different types of rotors can be used for wet and dry milling, aswell as different types of screens guarantee a top fibre quality. The unique design allows for fast and easy access for maintenance and service.

The machine can be equipped with various cleaning devices to avoid impurities like metal and stones in the milling chamber.

Dieffenbacher

Dieffenbacher

The machine is used for preparation of organic substrates for biogas production, wood-dust for energy and heat generation, wood-flakes for pellet production and many other applications. The working principle is based on the impact effect. Inside the impact chamber the material is resized with high kinetic energy by the fast rotating rotor and interaction of the particles itself. A final calibration is realized by screens. The ClassiSizer is able to process different and inhomogeneous input materials to variable sized final particles.

Bliss Industries

Bliss Industries

Bliss Industries, LLC is a leading manufacturer of size reduction equipment. Bliss maintains a reputation of manufacturing the most efficient, reliable and well-built equipment in the industry. Bliss offers the largest hammermill on the market, our ED-4460-TF hammermill with 7200 sq. in. of screen area. With the ability to provide a wide range of mill sizes, tip speeds and drive power, Bliss can more than meet your requirements for high quality at a reasonable cost.

Amandus Kahl

Amandus Kahl

The KAHL Pan Fiberizer provides optimum crushing and grinding of wet wood chips and torrified biomass. This grinding process is appropriate for wet raw and dry torrified material, and is an excellent alternative to a traditional hammer mill. The system does not require an aspiration system, nor explosion suppression, bagging houses or cyclones. There are no noise protection measures needed, the mill is smooth running in a very silent operation.

The Fiberizer is extremely cost effective due to the fact, that it uses shear force to grind and cut the fiber instead of the high speed – high impact principle applied in traditional hammer mills. Thus the energy required and the wear costs are less in comparison with old style hammer mills.

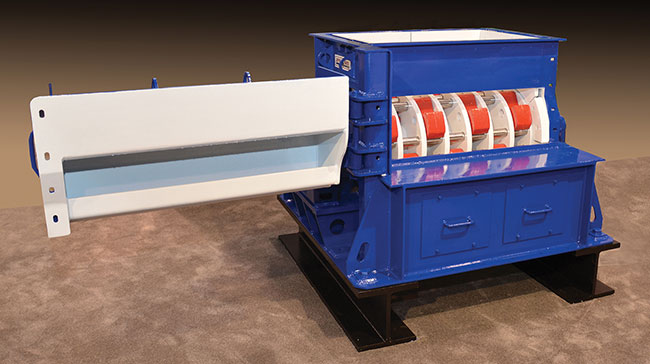

Schutte-Buffalo

Schutte-Buffalo

The Schutte-Buffalo Hammermill Series 15 Hammer Mill is the most efficient, high production fine grinder of its kind. Built specifically for the wood waste market it can process chips, shavings, bark, hogged scrap and other materials to the exact finished particle size required for downstream processing. With over 80 years of experience, Schutte-Buffalo Hammermill has built more fine grinding hammer mills for processing wood than any other hammer mill manufacturer.

West Salem Machinery

High speed, high volume hammermills with 20,000 fpm hammer tip speed for high capacity grinding to a small particle size. Features a large diameter hammer circle and throat widths from 20” to 60”.

These rugged mills have near full circle sizing screens to maximize production and deliver a consistent end product.

Print this page