Application of the MBBR and IFAS Technology in biological water treatment

July 5, 2017

By Christian Börner René Trübenbach / Mutag BioChip

July 5, 2017 - The detailed design and engineering of wastewater treatment plants is full of obstacles. Any mistakes made during the implementation can hardly be remedied.

Mutag BioChip blue (25 mm) from 2017.

Mutag BioChip blue (25 mm) from 2017. What is the reason? Worldwide, the MBBR as well as the IFAS technology are increasingly being applied for biological water treatment. Numerous qualified and well-skilled procedural biotechnologists with technical know-how are available for the engineering of suchlike plants. However, it is not quite unusual that unexperienced plant construction companies as well as plastic manufacturers without any process-technological knowledge try to implement, or rather said to copy this technology based on collected information.

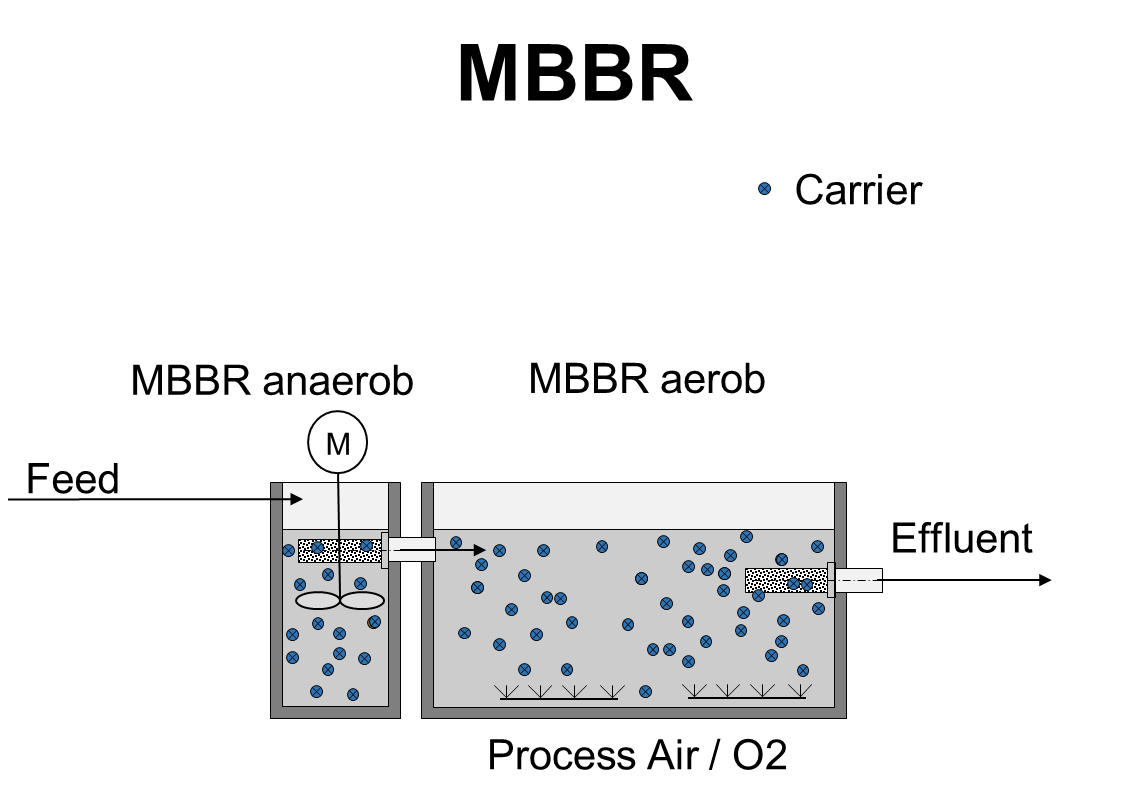

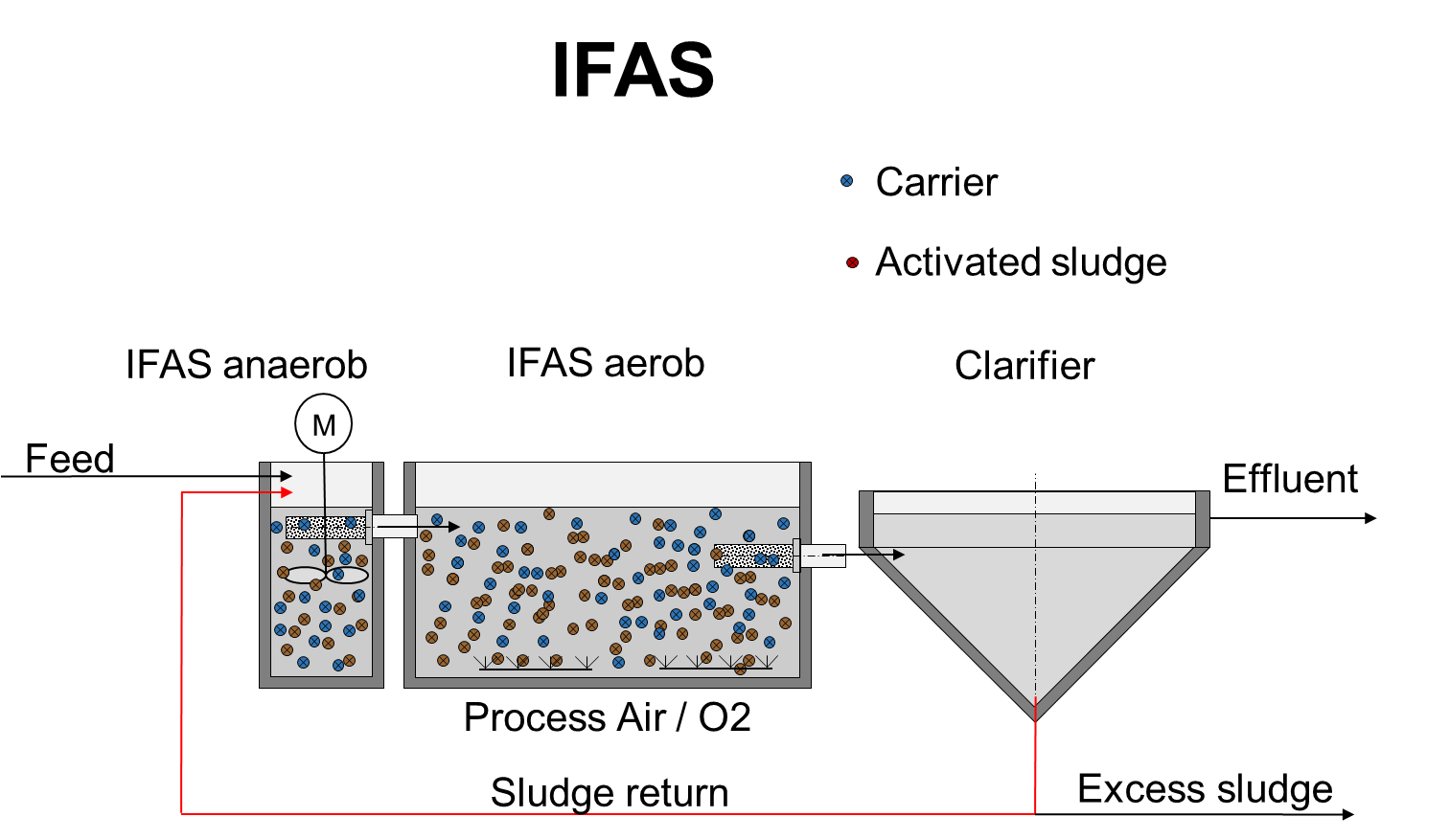

The term MBBR is the abbreviation of Moving Bed Biofilm Reactor, while IFAS stands for Integrated Fixed film Activated sludge System. At a first glance it seems to be easy: a reaction tank is filled with a plastic-made carrier which is mixed in water or in a water/sludge mixture, respectively. The difference between IFAS and MBBR is that in the IFAS system the activated sludge from the sludge recirculation is additionally used and hence the combination of activated sludge and carrier-fixed biofilms is used in the same reaction tank volume.

Which factors are important? Initially, the appropriate and complete task to be performed in the project in question has to be specified first. Apart from the space conditions and requirements on site, a detailed determination of the wastewater influent parameters and of the treated effluent quality is required.

The size of the MBBR/IFAS tanks and the related carrier media filling rate are determined based on the pollutant loads and in consideration of specific product factors of the carrier media. Here, the loads are being calculated from the flow rate (m³/h or m³/d) and the respective pollutant concentrations, e.g. COD (mg/l). Crucial factors for the dimensioning of MBBR/IFAS plants are the wastewater temperature at the design point, the yield and product specific removal rates (removal efficiency) of the carrier media chosen.

Why is the water temperature relevant? For the design calculation as well as for the comparison of techno-commercial design proposals offered by different suppliers, a detailed consideration of the water temperature in the MBBR/IFAS is highly essential. An incorrect assumption of the water design temperature results in the following effects:

If the design temperature is considered to be high, e.g. 35°C, a high biological removal rate will be considered in the calculation and hence the carrier media requirement as well as the reaction tank volume will be low (favourable price offer).

During normal plant operation, the relating result will be that at lower temperatures, e.g. at 25°C, the reaction tank volume and the quantity of carrier media will not be sufficient for complying with the discharge requirements. In consequence, further media will have to be added whereas it is questionable if this will be possible at all with regard to the admissible media filling rate (max 50 – 70%).

In case that the design temperature used for the calculation is considered to be low, e.g. 10°C, the tank size as well as the carrier media quantity will be correspondingly larger although the water temperature will most likely be higher in practice than assumed for the calculation. Larger tank volumes with higher carrier media fills are not negative in terms of the biological aspects, but they are unnecessarily increasing the investment costs (high price offer).

In order to obtain the appropriate design for your MBBR/IFAS plants, it is necessarily required to determine the minimum and maximum design temperatures and to simultaneously make sure that these values have really been taken into consideration.

For reasons of “competitiveness”, the real requirements are often not taken into consideration by the bidder. In case of certain missing data, it also happens that assumptions are made by the bidder in his own favor, without having explicitly asked the customer for providing the missing data. For this reason, it is hence indispensable to carefully review and compare any design proposal.

If there should be the need to specify the oxygen requirement for designing the aeration system, one should keep in mind that the higher one of the two water design temperature values is used for this purpose. The reason for this is that the oxygen dissolubility in warm water is worse than in lower temperature ranges. This reaction is hence completely reverse to the calculation of the removal rates.

As a consequence, the following general rule applies:

– the lower temperature ↓ is considered for calculating the required tank and carrier media volume

– the higher temperature ↑ is considered for the calculation of the oxygen supply

Why does the yield matter? For dimensioning MBBR/IFAS systems, the yield is another essential factor which impacts the tank size/carrier media volume and the oxygen supply. The yield is used for considering the biomass growth in the calculation; it is an “empirical value” obtained in pilot trials, reference plants and it differs depending on the individual origin of the wastewater. A wrong selected yield figure can be the reason for an inaccurate dimensioning of MBBR/IFAS plants. Any further, more detailed explanations on the yield would go beyond the scope of this article.

What is the reason for determining removal rates? As mentioned above, the carriers are substantially contributing to the pollutant removal (i.e. degradation of the wastewater pollutant load) in MBBR/IFAS plants and are hence the “centerpiece” required for an optimal performance. The removal rates required for designing MBBR/IFAS plants are the measuring unit of the “removal efficiency”. Generally, the carrier media supplier must know the removal efficiency of his carrier media; otherwise he transfers all risks to his customers. Removal rates are resulting from many years of operational experience with the product “carrier”, obtained from large-scale plants, pilot trials or lab-scale studies. Individual and project-specific factors such as the origin of the wastewater, specific wastewater characteristics, water temperature, nutrient & oxygen supply etc. have a significant impact on the removal performance. Providing general (i.e. global) removal rates is as irresponsible as copying them from other carrier types.

With regard to this, further differentiations should be made. Certain types of hollow-body carriers have been used in MBBR/IFAS plants for several decades, whereas their relating removal rates are available from publications. Due to various disadvantages of these hollow-bodies, further activities in Research & Development had been performed within the last ten years resulting in e.g. porous chip-type carrier made of foamed PE material.

During the years of product development and optimization, the technological market leader and carrier media manufacturer Multi Umwelttechnologie AG (Mutag) simultaneously made huge efforts in the process-technological application in many different types of wastewaters as well as fields of application in order to allow for giving reliable statements in terms of the removal efficiency of this special product.

If hollow-body carriers are applied, then the microorganisms are immobilizing on the carrier surface until they are being sheared off. This fact allows for a comparison possibility of the theoretically determined surface area. This is the reason for the surface area comparison of different product shapes and manufacturers.

A surface area comparison with a foamed carrier having a pore system will be meaningful only in a conditional way or not at all, which is due to the fact that the removal efficiency depends on the concentration of active biomass under the specific process conditions, as explained above. A comparison of the surface areas for evaluating the removal efficiency is possible to perform only after having conducted long-term comparative tests under exactly the same process conditions for the specific wastewater. If the Chip from 2008 with its pore system would have provided the same performance, it would surely not have become necessary to optimize the product to the Mutag BioChip blue which has an average diameter of 25 mm. The optimization of the pore system which holds a high amount of active biomass has been confirmed by means of extensive studies performed by Mutag as well as by several institutes/universities.

Summary: In comparisons, it is not the surface area of the porous Chips which is crucial for the removal efficiency but the quantity of biomass which can be immobilized per volumetric unit of carriers. There are dramatic differences in terms of the removal capacity when looking at pore systems, and a pure comparison of the surface areas may result in dire consequences with regard to the conceptual plant design. In order to minimize the risks of an inaccurate plant dimensioning, the removal performance of porous carriers used in the specific type of wastewater to be treated has to be proven on binding basis, and/or the bidder / plastic material supplier must possess the knowledge of the real performance data of the finally chosen carrier type in the specific case of application.

Please take seriously into account that any assumptions or estimations will not be of assistance to you and a simple comparison of the carrier surface area is not leading to reliable results.

Multi Umwelttechnologie AG has over 20 years of experience in the application of biofilm media in the treatment of wastewater. During this period, the company used almost every available type of biofilm carriers in numerous different large plants, types of wastewater and fields of application. The profound know-how which the company gained as a result, along with a very comprehensive database, enables it to make a well-founded assessment of the specific performance data of the in some cases extremely different carriers. Since Multi Umwelttechnologie AG was at no time linked to a particular supplier, the company was able – on the basis of the operational experience gained – to undertake targeted optimisation either of the carrier itself or of the process conditions. The emphasis here was on minimising operational problems arising from the shortcoming of “conventional” biofilm carrier media that cannot be overlooked nowadays. The thorough implementation of its requirements for an optimal carrier led to one result: the Mutag BioChip 25™. From the company’s point of view, this is currently the “best carrier available” specifically for treating types of wastewater which are rather difficult to treat by means of biological processes.

Print this page