Better yield from yeast

December 5, 2014

By Gabrielle Bauer

Like all industrial processes, the creation of pulp leaves a residue of waste. To the Canadian forest-products company Tembec, this waste has spawned a sideline business.

Long before the current biorefinery craze, Tembec decided to convert the waste into something of value: ethanol (ethyl alcohol), the two-carbon molecule that gives alcoholic beverages their kick and has a wide variety of commercial uses.

|

|

| Nicole Harner (PhD student) and Terri Richardson (MSc student) check the status of the fermenting yeast cultures.

|

Nestled in the rugged Temiscaming region of Quebec, Tembec’s pulp and paper mill incorporates an ethanol production facility, which produces high-purity ethanol from natural wood sugars extracted from the residue of the pulping process.

It wasn’t long before Tembec became a leading supplier of high-grade ethanol to Eastern Canada and the Northern U.S., with customers in a broad swath of industries. It didn’t hurt that the federal government’s Bill C-33, passed in 2008, mandated that ethanol comprise five per cent of gasoline by 2010.

There’s just one problem: the conversion process leaves much to be desired in terms of efficiency – and profitability.

Tembec produces the ethanol from spent sulfite liquor (SSL), a by-product of pulping. Rich in lignin and hemicellulose, compounds extruded from wood chips during the pulping process, SSL retains one ton of lignocellulosic material for every ton of paper fibre produced.

|

|

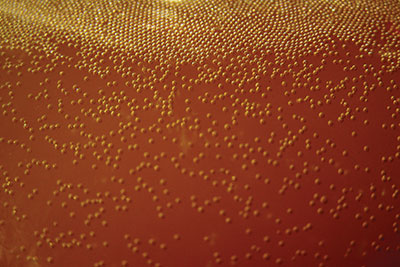

| The research team set out to develop ethanol-producing microorganisms that are more tolerant. |

The plant has been using the common baker’s yeast, Saccharomyces cerevisiae, to ferment SSL and produce ethanol. While the yeast does a fine job of converting the hexose sugars in the mix – chiefly glucose and mannose – into ethanol, it falls short in fermenting pentose sugars such as xylose. If this constraint could be surmounted, the plant could produce as much as 25 per cent more alcohol. As all entrepreneurs know, a 25-per cent difference can make or break a business venture.

Well aware of the problem, microbiologists have been trying to engineer yeast strains capable of fermenting both glucose and xylose to ethanol. Most of them have focused on tinkering with the S. cerevisiae strain to enable it to ferment xylose.

A team of BioFuelNet researchers has taken a different tack: improving the native pentose-fermenting yeasts Scheffersomyces stipitis and Pachysolen tannophilus. While these strains can also ferment hexose sugars, they have several unfortunate properties that limit the efficiency of the process, says team lead Dr. Hung Lee, a professor in the School of Environmental Sciences at the University of Guelph. For one thing, they’re highly sensitive to inhibitory substances in the SSL — such as acetic acid and furfural – that put the brakes on yeast cell growth and fermentation. The strains are also susceptible to glucose repression, meaning that glucose can prevent the yeast from fermenting the other sugars. Finally, these yeasts have a very low ethanol tolerance, so that even low concentrations of ethanol can stop the fermentation process in its tracks.

“The key challenge is to develop ethanol-producing microorganisms that are tolerant to all the inhibitory compounds generated during the wood-pulping process,” Dr. Lee explains. “The organism must also be able to ferment all the sugars, including pentoses, into ethanol.” (It should be noted that these inhibitory compounds are found not only in the SSL produced by Tembec, but also in the “lignocellulosic hydrolysates” produced by other companies seeking to convert biomass substrate into fuels or chemicals.)

|

|

| The organism must also produce a better yield.

|

In hopes of producing such strains, Dr. Lee’s team used simple genetic tools such as random mutagenesis and genome shuffling. They started by testing their genetically-engineered strains on SSL supplied by Tembec. Next, they put the strains to work on lignocellulosic hydrolysates supplied by BP Biofuels, FPInnovations, GreenField Ethanol, Lignol, and Mascoma Canada, among other partners. The effort paid off in spades: “We found that our modified strains ferment the sugars in the hydrolysates more efficiently than the native strains,” says Dr. Lee.

Dr. Lee feels confident that this cutting-edge research has commercial value. “We’ve had very encouraging results in terms of ethanol yield, and some companies have shown strong interest in our inhibitor-tolerant yeast strains,” he says.

Building on this success, the team plans to conduct similar genetic refinements on other pentose-fermenting yeasts. Dr. Lee’s team has also been collaborating with Mount Sinai Hospital in Toronto to sequence the entire genome of the improved yeasts to locate the genes responsible for inhibitor tolerance.

Dr. Lee is the first to admit that the venture might never have seen the light of day without funding from BioFuelNet. Along with financial backing, the organization provided contacts and networking opportunities. “Such connections can make the difference between a project stalling and getting off the ground,” he reflects, “getting the right people working together is how the magic happens.”

Print this page