Improving Ethanol Yields

August 2, 2013

By

Andrew Macklin

WHEN pennies become the difference between a hearty profit and a devastating loss, any investment that can be made to gain an extra financial advantage is worth considering.

WHEN pennies become the difference between a hearty profit and a devastating loss, any investment that can be made to gain an extra financial advantage is worth considering. Seeing both the short-term and long-term benefits of adding new technology, for the health of its bottom line, has led the Integrated Grain Producers Co-operative to make significant investments in its Aylmer, Ont., ethanol production facility.

|

|

| The addition of the corn oil extraction system, seen here during construction, will provide oil to help in the creation of biodiesel.

|

In less than 15 years, the IGPC facility has grown from little more than a pipe dream to one of the largest agricultural co-operatives in Ontario, and one of the largest ethanol production facilities in the country.

The idea was born when a group of farmers met and discussed their collective intention to start an ethanol facility somewhere in southern Ontario. The government of the day was offering incentives for starting a facility of this kind, and the farmers decided to move ahead with their new initiative. At conception, that group was just a handful of regional farmers. Today, that group has grown to somewhere in the range of 850-900 members.

The first stumbling block was finding a suitable location within the region to construct an ethanol production facility. The first proposed location was in Brantford, Ont., approximately 100 kilometres southwest of Toronto. When that location didn’t work out, Steve Peters, who was the MPP for the riding of Elgin-Middlesex-London where Aylmer is located, invited the IGPC group to the Aylmer Industrial Park. It turned out to be the perfect location for the newest ethanol plant.

|

|

| SMT allows for more starch to be made available to the yeast during the fermentation process, increasing the ethanol yield from the corn.

|

“We’re in the heart of the corn belt,” says Jim Grey, CEO of IGPC Ethanol Inc. “We’ve got great access to both rail and Highway 401. We’re also quite close to our co-product market, the DDG [dried distillers grains] market, and we’re not very far from our ethanol market. So as fate and luck would have it, we’ve ended up in a really good spot.”

Finding the needed finances for the project would prove to be even more complex. Over a five-year period beginning with the conceptualization of the project, the group worked to secure the different financial partners that would need to come on board in order to provide all elements of the financial model. Once local financial resources were tapped, including investments from the farming community, multiple levels of government were engaged to provide money from a variety of available grant programs.

“While this was going on, they began to look at opportunities to raise debt,” explains Grey. “We (IGPC) ended up with a banking syndicate led, at that time, by Societe General. So over that period of time, the group raised roughly $58 million in equity and approximately $65 million of debt financing. This allowed them to enter the various contribution agreements with the various levels of government to facilitate the construction.”

Involving the right partners

It was important in the early stages of the development of the IGPC ethanol facility to ensure that the right partners were added to the project. The right partners to help buy, sell and market for IGPC would contribute greatly to the success or failure of the facility. It was also made clear by government officials that, certain offtake agreements needed to be in place before funding would be secured, including the debt financing contracts.

|

|

| The Selective Milling Technology is added to the front end of ethanol production, making more starch available by a more thorough shearing of the grain.

|

Eco-Energy Inc. and Furst McNess were brought on board early in the process. Tennessee-based Eco-Energy Inc. was well respected for its ability to secure solid price points for the ethanol, and they signed an official offtake agreement with IGPC to market the facility’s ethanol production and find buyers. Those buyers now represent three of the biggest gasoline companies in Canada: Imperial Oil, Suncor and Shell. Furst McNess, whose Canadian head office is located in nearby Ingersoll, Ont., came on board to market and sell the ethanol byproduct, with an established customer base for dried distillers grains in Ontario.

The banks also insisted IGPC secure a steady supply of corn, ensuring that the co-operative would be able to meet its production targets. In order to make sure that the supply of corn would meet its demand, IGPC signed an agreement with Cargill.

“Especially in the early days when we were a bit of an unknown commodity in the market, it helped our credibility to have Cargill working with us to purchase our corn,” says Grey.

With a location and finances secured, the construction of the facility commenced in July of 2007. Using technology from ICM Inc., one of the most respected ethanol technology companies in the world, NAC (North American Construction Inc.) of Morriston, Ont. was hired to construct the plant.

The staff at IGPC has been successful at keeping the plant running efficiently since it came online in the fall of 2008. The ICM plant uses between 400,000 and 420,000 tonnes of corn per year, or an average of 35,000 tonnes per month. That volume of corn produces approximately 175 million litres of ethanol on an annual basis. That volume also produces an additional 170,000 tonnes of DDGS and WDS each year.

|

Making significant upgrades

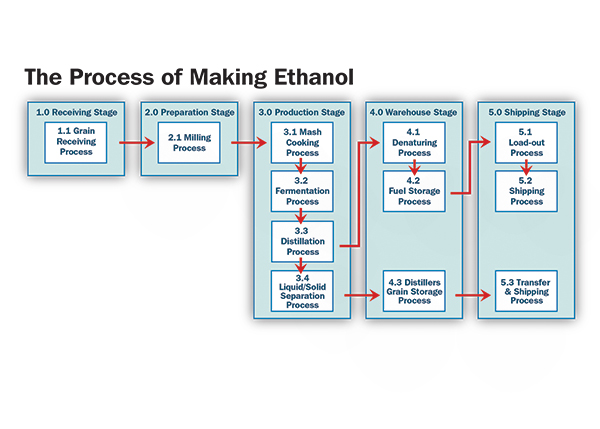

There are two additions being made to the IGPC facility this summer thanks to technology provided by ICM: Selective Milling Technology (SMT) and corn oil extraction technology.

|

|

| Work is being done on both the addition of the SMT system and the new corn oil system at the same time, with both expected to come online in the next few months.

|

Selective Milling Technology will allow IGPC to grind the same amount of corn but make more ethanol. According to ICM: “SMT provides more thorough shearing of the ground grain particles, making more starch available for conversion to sugars. Starch that is not made available to yeast can pass through fermentation untouched, exiting the plant as lost potential in distillers’ grain. These residual starches are not only lost ethanol, potential, they also add increased load on downstream equipment such as centrifuges and dryers.”

The additional ethanol yield created by the addition of the SMT system is targeted at 2-3 per cent, which in the case of the IGPC plant’s current production, should result in an increase of 3.5-5.25 million litres in ethanol yield.

“You must squeeze as much ethanol as you can out of every kernel of corn,” says Grey. “You have to keep driving for efficiencies because this really is a business of pennies; you have to run your plants in that way.”

Adding corn oil extraction technology provides another salable product that can be produced as part of the ethanol extraction process. The ICM Advanced Oil Separation System is built to provide maximum recovery of bio-oil from emulsion concentrate after the centrifugal phase of separation.

“Corn oil extraction allows us to take the oil out of the corn,” says Grey. “We have signed a Letter of Intent with a biodiesel manufacturer and they will be taking all of our oil to fill out some of their feedstock requirements to make biodiesel.” The Letter of Intent has been signed with Biox, a Hamilton, Ont.-based company, which currently produces approximately 67 million litres of biodiesel per year.

Looking ahead, IGPC continues to seek ways to improve the efficiency of its plant. Management continues to consult with ICM about emerging technologies to help improve yield. As far as expansion is concerned, there is no plan at this point, however, that could change if national demand for ethanol increases.

“Canada is in a reasonably good balance right now when it comes to the production of ethanol,” says Grey. “There is a certain amount of U.S. product coming in to Canada, but it heads into areas like Western Canada, which, obviously, does not have a lot of corn growing.”

The demand for ethanol production could increase though if the mandate for ethanol as a gasoline additive ever increases. Currently, nearly 900 million litres of the approximately 2.1-2.2 billion litres of ethanol needed for Canadian consumption comes from south of the border. But should the mandate increase, the demand for Canadian will rise substantially.

“Will we ever see the mandate increase? Certainly, from an industry perspective, we’d like to see that happen at some point in time,” explains Grey. “But to do that, areas like the GTA would have to blend at over the 10 per cent level just because of the logistics of this country. That poses some infrastructure difficulties, but as an industry, we’d be silly not to continue to push for greater inclusion rates.

Print this page