Biomass Boiler Buyers Guide

March 27, 2013

By Canadian Biomass staff

Nexterra is a leading provider of plant-scale energy from renewable waste systems that generates energy and fuels for a range of customers

Find our 2018 boilers spotlight here: www.canadianbiomassmagazine.ca/boilers/equipment-spotlight-boilers-2018-updates-6700

|

|

Nexterra Systems Corp.

www.nexterra.ca

Nexterra is a leading provider of plant-scale energy from renewable waste systems that generates energy and fuels for a range of customers, including district energy providers, industrial process plants and independent power producers. Nexterra systems integrate seamlessly with customer operations, providing both environmental and operational advantages, including high reliability and class-leading emissions performance. These systems convert local, renewable waste feedstocks into clean burning “syngas” that can be used as a substitute for natural gas and other fossil fuels in a range of applications. In addition to continuously improving its core gasification technologies, Nexterra has developed a syngas cleaning and conditioning system that produces engine-grade syngas. This enables the gas to be directly fired into an industrial internal combustion engine. Nexterra is also conducting research on the potential for high-value fuels and chemicals from syngas.

|

|

Location Bioénergie Inc.

www.locationbioenergie.com

Location Bioénergie provides biomass-fired boiler systems for rental. They range from 1.5 to 9 MW, with water-tube or fire-tube boilers (low or high pressure) for process or heating. The fleet of mobile units of different power meets the various needs of commercial, industrial or institutional clients. The company’s solution allows its clients to meet a temporary increase in the demand for hot water or steam. It is also the best solution to keep producing or heating during a shutdown of an existing boiler.

|

|

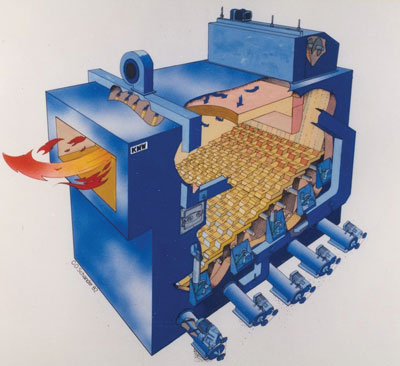

KMW Energy

www.kmwenergy.com

KMW Energy Inc. has more than 130 installations worldwide and the expertise to design and engineer customized bioenergy systems to meet your thermal heat and electric energy needs today and in the future. Our bioenergy systems are built to suit a wide range of applications including sawmills, remanufacturing facilities, hospitals, schools, pulp and paper mills, power utility plants, cogeneration facilities, district heating, and greenhouses, utilizing a variety of wood, agricultural or municipal solid wastes. KMW’s proprietary moving grate combustion system is the most fuel-efficient system available and translates into dramatic saving for your organization. KMW Energy Inc. is a full-service company. We can take your project from concept to completion; fuel testing, feasibility studies, system design, component fabrication and installation. KMW takes responsibility for the entire biomass system, from fuel handling, to hot water, thermal oil or steam boilers through to automatic ash disposal and on to turbines and generators.

|

|

Viessmann Manufacturing Company Inc.

www.viessmann.ca

Clean burning and efficient, Viessmann biomass boilers offer state-of-the art safety equipment and fully automatic operation in an efficient, environmentally friendly solution suited to a broad range of commercial and industrial applications. Viessmann Pyrot (512 to 1843 MBH) and Pyrotec (1330 to 4268 MBH) wood-fired boilers feature advanced combustion technology to match the quality of modern gas combustion while generating comparable CO and NOX emissions. When outfitted with Viessmann digital modulating output controls, these boilers achieve an excellent efficiency up to 85%, making them ideal for integration with renewable energy systems that may also incorporate Viessmann gas/oil-fired boilers (for peak loads/biomass boiler backup), solar systems and DHW storage tanks. All Viessmann wood-fired boilers are built to ASME, Section IV requirements and have been tested to CSA/UL Safety Standards.

|

|

Hurst Boiler and Welding Co., Inc.

www.hurstboiler.com

Hurst Boiler Co. specializes in the manufacturing of modular biomass boiler systems with outputs ranging from 28 kW to 52 MW thermal. Boiler vessel designs (CRN registered) include firebox, vertical tubeless, hybrid water/ fire-tube, and water-tube. Operating pressures range from 15 to 900 psi, with steam superheat available. Modular biomass thermal to electric cogeneration systems are offered in 250 kWe, 500 kWe, 1 MWe, 3 MWe and 5 MWe packages. Hurst manufactures seven different types of biomass stoker/gasifiers, which have used almost 2,000 different types of biomass fuels over the last 40 years. Hurst has grown with more than 350 employees, becoming an experienced, reliable, and stable biomass thermal system supplier.

|

|

Pratt & Whitney

www.pw.utc.com

Pratt & Whitney Power Systems (PWPS), a division of United Technologies (UTC), is committed to providing clean, efficient and reliable power within the renewable energy market. Pratt & Whitney PWPS’ Organic Rankine Cycle (ORC) power plants provide heat to electric power generation for biomass, geothermal, heat recovery, and concentrated solar applications. Our biomass ORC systems for cogeneration allow simple and highly efficient production generation of electric power and heat with sizes ranging from 1 kW to 10 MW. PWPS’ ORC products include benefits such as 24/7/365 remote control and monitoring, 195°F to 660°F (90°C to 350°C) temperature range, and standardized components and assembly processes.

|

|

Wellons

www.wellonsfei.ca /www.wellons.ca

Wellons, Wellons Canada and Wellons FEI are all part of the Wellons group of companies, supplying the North American market with wood fired energy systems and dry kilns for the past 40 years. Wellons FEI supplies energy systems using a stepped grate technology with a fully automatic ash extraction system. Capacity of the systems we build is appropriately sized for medium- and large-sized district heating systems such as hospitals or a university campus. Applications include process and space heating using hot water, steam or thermal fluid. Wellons offers wood-based cogeneration solutions as well, and some of its units can and have been used as hot gas generators to send energy to rotary dryers in order to dry wood fibre for pellet plants.

|

|

Wood Energy Solutions

www.woodenergysolutions.co.uk

A new range of pellet boilers has arrived on the Canadian market from Irish manufacturer WES (Wood Energy Solutions). E-COMPACT pellet boilers offer advanced boiler technology, which allows the installer to use the existing infrastructure to heat the property in a cost-effective and comfortable manner. WES offers a “best in class” automated pellet boiler that requires minimal maintenance each month. The E-COMPACT boilers are more than 90% efficient. Boilers range in outputs from 28 up to 250 kilowatts, so they are suitable for small dwellings to large commercial buildings. All E-COMPACT boilers sold in Canada are manufactured to ASME Code and are UL/CSA certified. E-COMPACT pellet boilers are available in Canada through Compact Appliances Inc., Sackville, New Brunswick, and J&R Mechanical in Yellowknife, Northwest Territories.

|

|

Combustion Expert Inc.

www.combustionexpert.com

For over 15 years, Combustion Expert Inc. has manufactured biomass-fired boiler systems from 200 kW to 30 MW and greater. It designs fully automated systems that use any type of woody biomass as fuel, from pellets to barks with 55% moisture content and more. Whatever the needs are, hybrid boiler, water-tube or fire-tube boiler, low or high pressure, Combustion Expert creates a custom unit for every client., including industrial, commercial and institutional.

|

|

Ideal Combustion

www.ideal-combustion.com

Ideal Combustion offers biomass gasification combustion technology with horizontal reciprocating grate furnaces in the range of 150 kW to 30 MW thermal and cogeneration capacity from 1 to 5 MW electric. The systems are suited for greenhouses, schools, hospitals, sawmills, and more. They accept any type of fuel, and up to 60% moisture content. The systems feature hydraulic ram biomass feeders for trouble-free operation, double combustion chambers, automatic boiler tube cleaning and ash removal systems, and fully computerized controls with VFD. Little headroom space is required. The systems use biomass gasification technology for cleaner combustion gases, and have high overall efficiency due to the cleanness of the exchanger. The systems are compatible with any type of heat exchanger, including steam, hot water, thermal fluid, and hot air.

|

|

Krann Engineering Ltd.

www.krann.ca

Krann offers biomass boiler systems in 1 to 20 MW range for both hot water and steam, powered by Krann gasification furnaces. Typically, no filters are needed for flue gases handling because of the low emission levels. These systems can be used to generate electrical power through either the steam turbine or the ORC module. Fuels used include hog fuel, shavings and recycled wood waste, with moisture content up to 60%. Applications for the systems include sawmills, greenhouses, drying facilities, municipal buildings and hospitals. Systems are turnkey, fully automated from fuel storage to exhaust.

Print this page