Biomass Emissions Control

June 5, 2013

By canadian biomass

EDITOR’S NOTE: The companies submitted the following materials. All statements and claims are attributable to the companies.

EDITOR’S NOTE: The companies submitted the following materials. All statements and claims are attributable to the companies.

Evergreen Engineering

|

|

Evergreen Engineering can help your facility determine the best strategy for complying with emissions control requirements. Every site is unique and Evergreen Engineering offers customized solutions to comply with local, state and federal environmental regulations.

For instance, EPA issued Boiler MACT rules in March 2011, with compliance for Area Sources required by March 2014. Final rules for Major Sources are imminent, with compliance required within three years of the final rules. Evergreen Engineering can help you determine the best strategy for complying with Boiler MACT. Up-to-date emission inventories are essential to begin determining your facility’s status.

Steps to compliance:

- emissions testing and compliance options study

- engineering and procurement

- major equipment fabrication, delivery and installation

- startup and testing

- energy assessment

- boiler tune-up

Evergreen offers an economical step-by-step program to determine your facility’s individual Boiler MACT compliance status. Evergreen Engineering’s approach draws on its deep well of process expertise as well as experience in modelling and analysis to understand operational variables. Evergreen will confirm emission inventory estimates; perform a status check of your situation relative to the new Boiler MACT rules; identify and evaluate potential compliance strategies; and recommend a path forward to help you achieve compliance.

Evergreen Engineering is an industry leader in providing detailed engineering for integrating new emissions control equipment into existing facilities and the environmental permitting associated with that equipment. Visit www.evergreenengineering.com .

Met-Pro Environmental

|

|

Met-Pro Environmental Air Solutions (MPEAS) provides the total solution for all of your product recovery and air pollution control needs. Its diverse and synergistic solutions and products address the world’s growing need to meet stringent emission regulations, reduce energy consumption and employ innovative, green technologies.

The MPEAS product line includes: Duall brand scrubbers (packed tower) for air quality and odour control solutions and wet dust collection (venturi); Flex-Kleen brand dry dust collection and product recovery solutions; Systems brand thermal oxidizer VOC removal solutions; and the BioReaction Bio-Pro brand advanced vapour phase biological systems including bioscrubbers, biological trickling filters and biofilters. Since the acquisition of BioReaction Industries (BRI) in October 2010, and rebranding the BRI line to Bio-Pro, MPEAS has an established, multi-unit presence for hazardous air pollutant and VOC control using biofilters in the wood products industry. Thermophilic design and operation is a viable option, with operating temperatures in the 135 to 165°F (wet bulb) range.

In addition to the MPEAS equipment listed above, Met-Pro Corp. manufactures pumps (Dean, Fybroc and Sethco), and Strobic exhaust fans.

MPEAS and Met-Pro Corp. provide a complete line of spare parts and an experienced field service organization for servicing and maintaining all air pollution control equipment, regardless of the manufacturer. Visit www.met-pro.com .

Metso

|

|

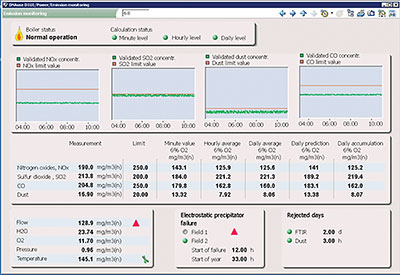

In recent years, tightening environmental legislation has dictated increasingly complex and accurate monitoring of emissions from large combustion and waste incineration plants. For the bioenergy industry this means not only improving plant efficiency to reduce emissions but also adopting progressively more comprehensive emission monitoring and reporting solutions. Improved combustion control is vital in bioenergy plants, where variations in fuel quality (heating value, moisture content, etc.) affect combustion efficiency and flue gas emissions. A successful automation solution gives the operator a feel for the process and enables corrective actions in case of any imbalances in the plant and operations.

The Metso DNA FBB Combustion Manager is a supervisory level control application for optimum combustion control of both bubbling fluidized bed (BFB) and circulating fluidized bed (CFB) boilers. The application achieves easier and more stable operation, minimizes flue gas emissions (SO2, NOx, etc.) and improves combustion efficiency. Achieving more stable operation can also minimize the O2 content in the flue gases leading to higher overall boiler efficiency and thus more economical operation. Optimized fuel usage is assured while keeping selected process variables such as bed, combustion chamber (furnace) and cyclone temperatures within acceptable limits.

The integrated information management system includes a Metso DNA Historian database and several Plant Management applications for monitoring and reporting, such as fuel data management, emission reporting, as well as balance and cost allocation reporting. Metso has developed comprehensive emission monitoring and reporting solutions customized according to the plant’s environmental permit and special monitoring needs. Compulsory monitoring calculations can be complemented by emission forecasting shown on the operator’s display, a feature that improves the proactive control of the plant’s emission levels.

With the growth in bioenergy, Metso’s plant automation and information management solutions are the ideal tools to meet sustainability targets and emission compliance. Metso’s full scope of products and services are designed to meet current and future needs from project engineering to high process availability and continuous performance improvement. Scalable to individual process demands, integrated solutions from combustion control and optimization to flue gas emission control and monitoring are supported by an extensive global network of local services. Visit www.metso.com .

PRD Tech

|

|

Emissions of volatile organic compounds (VOCs) from wood product industries is an important environmental issue that needs improved technologies for achieving higher treatment efficiency, lower energy consumption and total cost. Traditionally, VOCs have been treated by thermal oxidizers, which consume large volumes of natural gas to destroy the organics at high temperature. Thermal oxidizers suffer from high operating costs mainly due to natural gas consumption. Chemical oxidation processes utilize oxidizing agents, such as ozone or hydrogen peroxide, which results in high operating costs due to chemical consumption. In addition, chemical oxidation using hydrogen peroxide also produces byproducts, such as carbon monoxide. Biofiltration offers a simple, low operating cost, high treatment efficiency system that utilizes natural bacteria to convert the VOCs to carbon dioxide and water.

PRD Tech, Inc. has developed the “Dual-Phase Biofilter,” which simultaneously treats the organic compounds in both the air and water phases. The Dual-Phase Biofilter is much more efficient than a standard biofilter with plastic/compost balls, has a smaller footprint, and can handle both dryer and press vent gas flows. It has an overall lower cost than any other treatment system. The main advantages of the Dual-Phase Biofilter system are: (1) has a smaller footprint than a standard biofilter; (2) does not generate any unwanted, toxic, byproducts, such as carbon monoxide; (3) can handle a wide variety of organics; (4) can handle higher inlet gas temperatures from dryers; (5) is capable of handling particulates in the inlet gas; (6) represents the lowest investment and operating costs of any treatment system; and (7) is capable of achieving high treatment efficiencies exceeding the treatment levels mandated by MACT standards. Visit www.prdtechinc.com .

Pro-Environmental, Inc.

|

|

Pro-Environmental, Inc. (PEI), a subsidiary of M-E-C Company, is a leading provider of thermal based air pollution

control equipment. PEI supplies cutting-edge gas treatment technologies and services. With more than 2,500 installations worldwide, PEI offers valuable single-source solutions to its customers.

PEI is dedicated to the design and manufacture of energy-efficient air pollution control systems with emphasis on regenerative thermal oxidizers (RTO), and PEI’s experienced nationwide service team provides superior service.

PEI designs, manufactures, maintains and repairs air pollution control systems. It specializes in custom installation, which means it can tailor the product and results to your specific application. Whether you have a large facility and require a complex installation or have a small-scale application, PEI will a find solution to meet your environmental compliance requirements. Visit www.pro-env.com .

Scheuch

|

|

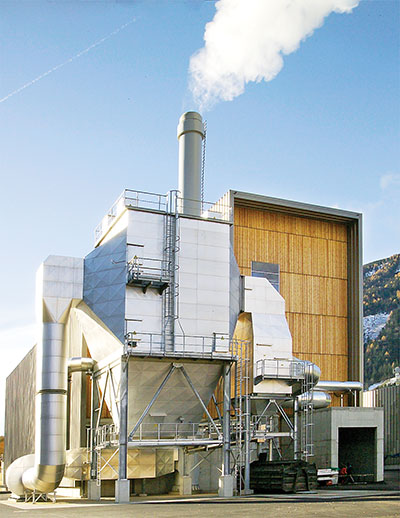

Depending on the application, the composition of the flue gas and the required clean gas values, Scheuch utilizes different system solutions for efficient particulate removal and emission control. Scheuch has extensive engineering experience in filtration technology and practical experience with thousands of filtration plants in operation around the world. Scheuch offers a complete equipment program for particulate and pollutant reduction as well as custom engineered solutions that perform at the highest technological level with respect to both ecology and energy efficiency. The company’s products

include:

Centrifugal separators for pre-separation:

High-quality mechanical separators are used for simple particulate removal and pre-filtration of particles from the exhaust gas created by biomass combustion processes. These mechanical separators include tangential cyclones, spark or rotary separators and multi-cyclone filtration equipment.

Electrostatic precipitators:

Electrostatic processes are used in applications requiring separation efficiencies of more than 99% and clean gas particulate levels of < 20 mg/Nm3 (< 0.008 gr/dscf). Scheuch’s innovative solutions include the design and supply of environmental control equipment such as dry electrostatic precipitators for biomass-fired boilers or wet electrostatic precipitators for wood pellet dryer applications.

Dry electrostatic precipitator for flue gas cleaning:

Single- and multi-field dry electrostatic precipitator systems provide high PM removal efficiencies for boiler sizes from 250 kW to 100 MMW. The advantages of the dry electrostatic precipitator include hot gas resistance, high separation efficiency, low operating costs and long service life.

Wet electrostatic precipitator for cleaning dryer exhaust gases:

Wet ESP products embody Scheuch’s extensive knowledge and understanding of particulate control and removal as well as essential water treatment techniques to provide high particulate removal efficiencies, system cleanliness and ease of operation.

Bag filters:

Scheuch offers a complete range of bag filters for particulate control as well as additional systems configurations to remove SO2, HCL, HF and other gaseous substances such as heavy metals, dioxins and furans.

“Scheuch provides proven technology for emission controls in numerous industrial applications and for the energy industry in particular. Superior design concepts, high-quality manufacturing and installation as well as after-sales technical assistance or service are part of our full line,” states Elwin Grassl, general manager of Scheuch Inc. Visit www.scheuch.ca .

SolaGen

|

|

For more than 25 years, SolaGen Inc. has provided the wood bioenergy industry with low-emission energy and dehydration systems to meet the tightening landscape of environmental regulation. SolaGen has promoted the idea that emissions should be controlled at the source by minimizing, at inception, the creation of pollutants.

Coupled with low emissions, these solutions have provided its clients with efficient hardware that delivers on the lowest possible cost of ownership.

The EnerTek series of biomass energy hardware qualifies as a Low NOx combustion system and can be engineered and manufactured as an Ultra Low NOx version.

This burner has the unique ability to operate with combined low excess air, CO, VOC, NOx, and particulate emission levels. The design utilizes proprietary staged combustion and flue gas recirculation techniques that reduce adiabatic flame temperature, thereby minimizing the conversion of fuel-bound nitrogen to NOx and creation of thermal NOx. The EnerTek combustor concurrently operates with low CO creation, which competing designs are unable to accomplish when NOx reduction techniques are employed. The EnerTek system is available in sizes from 10 to 200 MM Btu/hr and features full fossil fuel backup capabilities. It is an ideal solution for all boiler, dehydration and thermal fluid applications.

SolaGen’s unique approach to the design and manufacturing of dehydration systems is grounded in the principle that each application is different and end-user specific. Environmental compliance is met with technology and experience that provides the highest process efficiency and the lowest net stack flow rates in the industry. The basis for low dryer stack flow rates is directly related to the energy system’s operating excess air rate. Utilizing the EnerTek combustion system as the dryer’s energy source will allow for the industry’s highest stack gas recycle rate, which will reduce dryer emissions and fuel consumption considerably over existing technologies. Visit www.solageninc.com .

This article originally appeared in Wood Bioenergy June 2012, and was reprinted here with permission.

Print this page