Canada’s wood pellets: a responsible source of clean energy

July 15, 2020

By The Wood Pellet Association of Canada

Figure 2. Forest residues

Figure 2. Forest residues Canada’s forests are some of the most resilient and sustainably managed in the world. They are subject to stringent environmental regulation, careful management and extensive third-party certification. That’s why customers requiring sustainable biomass products have confidence in the Canadian wood pellet sector.

The Canadian wood pellet sector exists primarily to make better use of forests that are already being harvested. As our ability to process a broader range of wood fibre has improved, it has allowed us to decrease not just sawmill residues, but harvest residues, and support other, government-led initiatives to rehabilitate damaged, dead or understocked stands. This creates room for new forests that improve wildlife habitat and carbon capture.

Canada’s traditional forest industry is well-established. Forest products like lumber, structural panels, pulp, paper, tissue and newsprint are widely known. However, wood pellets are still relatively new and not as broadly understood. The Canadian wood pellet industry first gained momentum in British Columbia in the mid-1990s when the provincial government required sawmills to close their waste-wood beehive burners. These burners were common in communities throughout B.C. and the public had become tired of endless smoke, particulate emissions and wasted wood fibre. As beehive burners closed, pellet plants were built to make a new product from sawmill waste and in short order, plants spread throughout B.C. and across Canada. Today, Canada has nearly 50 pellet plants that sell their product for domestic and commercial heating and as a clean, low-carbon, renewable replacement for coal in electric power plants around the world.

As Canadian wood pellet producers have matured, they have expanded the kinds of raw material they use. They started by using sawdust and shavings from sawmills that were formerly burned and wasted in beehive burners. Now, increasingly pellets are being made from harvest residues – tree-tops, branches and low-quality logs that have been left behind after primary harvesting has occurred. This is material that has been rejected by sawmills, panel-board plants and pulp mills.

Maximizing the value of every tree

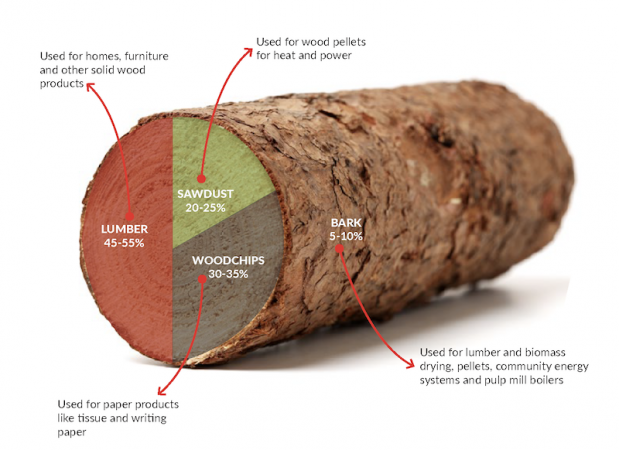

Canada’s forest industry is highly integrated and maximizes the value of every tree harvested. This means that producers assess the tree quality to determine what product they will make from each log. Multiple co-products are created when a sawmill processes a log (Figure 1). The primary product is lumber which, on average, uses 45 per cent of each log. Thirty to 35 per cent of each log goes to pulp chips, which are sold as raw material for pulp mills; 20 to 25 per cent of each log becomes sawdust and shavings which are used to make pellets; and five to 10 per cent of the log is bark, which is mainly used for energy for lumber and biomass drying, but can be used in pellets too. The pellet industry has enabled sawmills to improve forest utilization and to maximize both jobs and value from the forest for the benefit of all Canadians. Today, on average, the sawmill residues account for more than 90 per cent of the fibre input for pellet plants, although there are individual plants that use more or less.

Turning forest residues and low-quality logs into clean energy

In Canada, it is normally the sawmills who carry out primary harvesting and are responsible for sustainable forest management. Forests may be either clear cut or partially cut, depending on the characteristics of individual forest ecosystems and the best conditions for reforestation. Regardless of the system of cutting, blocks are designed to leave tree patches behind to serve a variety of purposes from providing cover and habitat to wildlife to sheltering the next generation of seedlings.

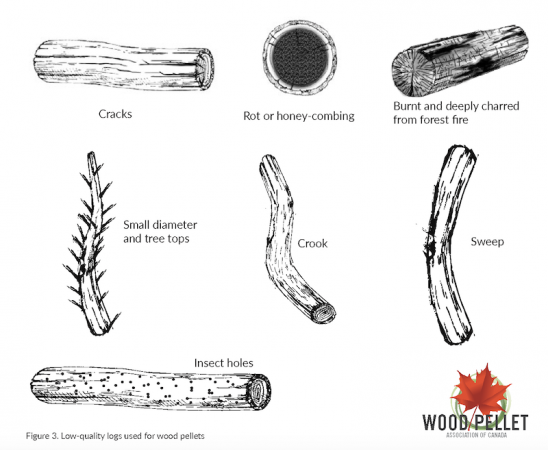

Recently, the wood pellet sector has emerged as a secondary harvester. This means they use the forest residues comprising low quality logs (Figure 2) and branches and tree-tops (Figure 3) that have been left behind by the primary harvester (Figure 3). This material would otherwise be burnt so as to reduce fuel buildup and forest fire risk or be wasted. Low-quality logs include those that have been rejected by sawmills, panel board manufacturers and pulp producers due to their poor quality. These include logs with splits, cracks, over-sized branches, rot, excessive sweep or crook, small diameter and those that have been burned or charred (Figure 3). On average, the pellet sector uses about 10 per cent harvest residues and low-quality logs for raw material, although individual plants may use more or less.

Good forest stewardship practices promote balance. Historically, much of the larger woody biomass left on the block has been piled and burned to reduce fuel for future forest fires and improve opportunities for replanting. The Canadian wood pellet sector can now convert that waste into energy. Careful planning by forest professionals ensures sufficient forest biomass is still left in the forest to decay and provide nutrients, contribute to biodiversity and provide habitat for small mammals.

Canada’s forest sector harvests less than one per cent of Canada’s commercial forests each year. The wood pellet sector uses only a tiny fraction of the harvest, totally less than 0.04 per cent of Canada’s annual forest harvest. However, pellet producers are using the portion of the forest – sawdust, shavings, harvest residues and low-quality logs – that has been rejected by the other traditional forest sectors – sawmills, pulp mills, and panel-board plants.

We have been proud to use our innovation and investments in the salvage efforts to turn what others viewed as waste into an energy source that supports thousands of jobs and local communities and is in demand around the world as an environmentally friendly alternative to fossil fuels.

Print this page