The latest in conveyor technology

June 5, 2015

By Staff Report

June 5, 2015 - With more than 500 installations worldwide, the BRUKS Tubulator has developed into the smartest transport system on the market.

BRUKS

BRUKS

With more than 500 installations worldwide, the BRUKS Tubulator has developed into the smartest transport system on the market. A BRUKS Tubulator has up to 40% higher capacity than comparable conventional belt conveyors. Low maintenance cost, low noise level and no need for catwalks are further advantages. The conveyor belt is carried on an air bed as compared to conventional idlers. The elimination of idlers reduces energy consumption and operational costs. This fully enclosed transport system lives up to the most rigorous environmental demands for dust-free, spill-free as well as silent operation. Pellets and other bulk materials are transported at high capacity with low energy.

![]() Brunette Machinery

Brunette Machinery

Unique and simple in its design, the first thing you’ll notice about Brunette Machinery’s SmartVIBE Vibrating Conveyor is that it has no coil springs or external balance beams. The Brunette SmartVIBE enables the operator to vary the conveyor’s feed speed using a VFD while remaining completely balanced. This new technology allows systems to be optimized based on loading efficiency levels.

B.I.D. Bulk Material Handling

B.I.D. Bulk Material Handling

Design, supply, manufacture and delivery of woodyard fuel handling system for new 75 MW biomass power plant. Scope included the supply of 3 truck dumper systems and receiving hoppers, a disc screen and a hog/crusher to process oversize fuel, the steel structure to support/enclose the screen/hog arrangement, a multi-strand drag chain reclaim hopper, 2 traversing screw reclaimers, dual screw conveyor, 2,800 ft of belt conveyors complete with trusses, galleries and bents, and all interconnecting chutework.

Jeffrey Rader

Jeffrey Rader

Jeffrey Rader, a brand of TerraSource Global, provides high-pressure, low pressure, and vacuum conveying systems for pulp & paper mills, biomass systems and boiler direct-injection systems. Pneumatic conveying rates of more than 1000 tons per hour can be achieved. Equipment includes ruggedly-built rotary valves, cyclones, wear back elbows, ducting, and blowers. With more than 50 years of experience and thousands of installations worldwide, Jeffrey Rader has the application knowledge to design and build your pneumatic conveying system.

Buhler Group

This trough chain conveyor RFKG Heavy-Duty Line is suitable for a wide range of applications in silo plants and processing industries. During the intake process it conveys the material from the intake hopper of freight trains or trucks. Then, it distributes the material to the different silo cells or discharges material from the silo cells. With its chain conveyor RFKG Heavy-Duty Line, Bühler offers a high-capacity conveyor capable of handling up to 1,200 tons of material per hour over distances of up to 150 meters.

Clarke’s Industries

Clarke’s Industries

Clarke’s Belt Conveyors are a practical and economical way to quickly move large quantities of material relatively long distances. Belt Conveyors usually require less horsepower to operate than chain conveyors, or pneumatic conveying systems, require little maintenance and operate pollution free.

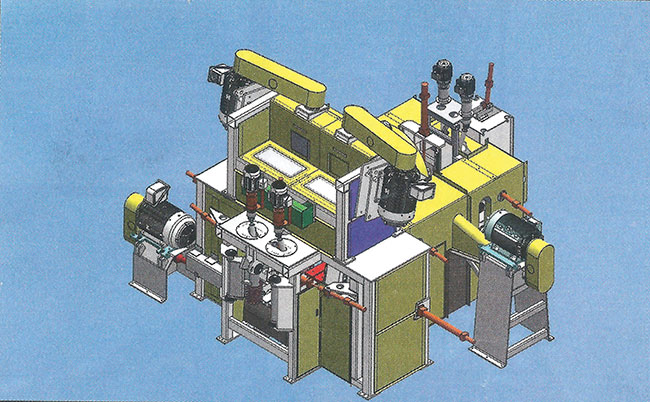

Concept-Air

When a sawmill uses the Concept-air team to develop a dust collector, she finds an ally capable of support in improving productivity. Thanks to its mastery of processes, Concept air is able to propose equipment that enable it to use wood in full, up to the finest particle, while helping to improve the quality of its products.

Rodrigue Metal

Rodrigue Metal

Rodrigue Metal offers a range of both belt and screw conveyors for effective movement of wood waste, shavings, sawdust, fibres and chips. Customized solutions can be built for biomass customers based on necessary volume, density and distance demands. Rodrigue Metal conveyors are also customized using mild steel or wear-resistant steel construction based on customer preference.

Walinga

Walinga

Move your bulk safely without potentially dangerous augers or airborne particulates and dust. ULTRA-VEYOR systems are remarkably efficient and easily maintained

with all moving components and service points located on the base unit. The system is usually installed semi-permanently wherever it’s needed, but needs can change, integrated forklift lift points make base unit relocations a breeze.

Optimil

Optimil

The heart of every EDEM Medium, Heavy and Extra Heavy-Duty vibrating conveyor is a rugged coil spring/eccentric shaft drive assembly. While simple in design, our coil springs are noted for their outstanding performance, and the unique EDEM design has the lowest horsepower requirement of any drive on the market today. Power is provided by a premium efficiency, TEFC electric motor and standard “V-Belt” drive. Each conveyor is custom designed and engineered to suit the customers exact requirements.

Superior

Superior

Superior Industries Inc. says it manufactures the highest-capacity telescoping radial stacker on the planet. Measuring 72 inches wide by 190 feet long, the high-capacity TeleStacker Conveyor can stockpile aggregates and other bulk material at rates up to 5,000 tons per hour. Since building its first telescopic radial stacker in 1997, Superior has since designed and built 1,000 more units.

KPI-JCI

KPI-JCI and Astec Mobile Screens has released a new 170-foot-long SuperStacker, its latest model of telescoping stackers designed to minimize stockpile segregation and increase stockpile capacity. The 170-foot SuperStacker is an addition to the new generation of SuperStackers that eliminates the echain, thereby reducing field maintenance.

Thor Global

Thor Global

Standard features make the ThorStacker the most all-inclusive telescopic conveyor on the market. Patented Fully Braced Undercarriage allows the upper and lower portion of the undercarriage to be fully braced at all times, even when completely raised. Patented LES (Load Equalizing System) provides a structure with greater support and longevity under the stresses of heavier loads.

MASABA

MASABA

Built with the same precision and craftsmanship as the original Magnum, the Low Profile Magnum design offers a lower feed height and greater maneuverability while still offering strength with a large truss depth and wide footprint. The Masaba Magnum telescoping radial stacker is the complete Low Profile Package.

McCloskey International

McCloskey International

The McCloskey Track Stacker is a 915mm x 19.8m track mobile stacking conveyor, allowing quick and easy movement. The adjustable feedboot allows the hopper side to be raised, reducing impact when being fed from screening plant side conveyors.

PROCESS BARRON

PROCESS BARRON

Our material flow handling conveyors are designed to reduce maintenance and maximize efficiency. ProcessBarron builds feed conveyors to endure a wide array of factors. To prevent corrosion and abrasion, ProcessBarron’s feed conveyors are fabricated with specialized alloys and coatings.

ALLIED BLOWER

ALLIED BLOWER

Allied Blower provides design, fabrication, installation, and service expertise in conveying equipment. Allied creates systems for dust control, wood, and pneumatic conveying.

Print this page