CSA publishes first Canadian guide for wood chip fuel

September 10, 2019

By Sebnem Madrali and Jaime Fernandez

Covered wood chips storage at a producer’s site. A 465 m2 tension fabric dome erected atop three rows of concrete blocks with an asphalt floor. Photo courtesy Vincent Rutter, Biothermic Wood Energy Services.

Covered wood chips storage at a producer’s site. A 465 m2 tension fabric dome erected atop three rows of concrete blocks with an asphalt floor. Photo courtesy Vincent Rutter, Biothermic Wood Energy Services. A new CSA SPE 2254:19 Guide to Wood Chip fuel: Characteristics, supply, storage and procurement was published in May 2019. This first edition of the guide was developed under the CSA banner with technical guidance from Natural Resources Canada (NRCan) and industry stakeholders. The guide aims to build confidence in an emerging market by linking players in the wood chip fuel supply chain and to become a communication tool by bringing common terminology and language to the marketplace. It is available for online purchasing at CSA web site store.csagroup.org.

Why wood chip fuel?

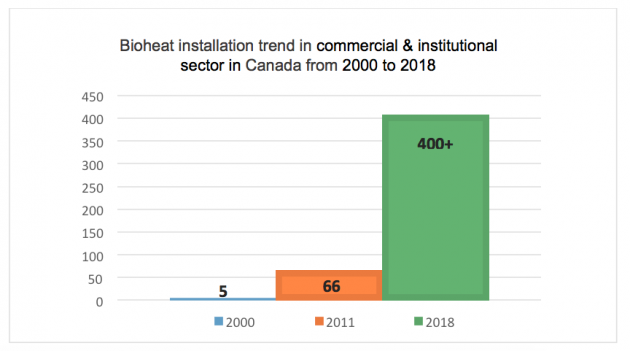

Wood chips are well suited to meet energy needs for space heating and hot water in buildings, communities, or campuses, and displace conventional fossil fuels, such as oil, propane, natural gas and electricity. As a renewable, locally available low carbon fuel source, wood chips are also a less costly option compared to fossil fuels. According to NRCan’s Canadian Bioheat survey results, the biomass heating sector in the commercial and institutional market in Canada has been demonstrating strong growth over the last two decades: 400+ bioheat installations in 2018 compared to 66 in 2011 and only 5 in 2000. Almost half of the existing bioheat installations are using wood chips as their primary fuel.

Why a Canadian wood chip fuel guide?

Wood chip fuel supply chains can be complex. At present, wood chip production is closely linked to forest operations and businesses such as loggers, land clearers, sawmills, urban wood /tree services, woodland management services and waste wood recycling operations. The practices and techniques used in the current supply chain are geared towards meeting the needs and product specifications of traditional forest products such as pulp and paper, dimensional lumber and wood panels. While widely used in Europe, wood chip fuel is a relatively new product in the Canadian heating market. Wood chip fuel quality and consistency can be highly variable depending on the wood chips’ origin and sources, processes used in preparation, handling and storage practices.

Buyers and users do not think about the quality of heating oil or gas when purchasing, because strict standards are in place that make sure these fuels are consistent. Until recently there were no wood chip fuel standards in Canada. In 2015, CSA adopted a series of solid biofuels standards, known as CAN/CSA-ISO 17225 series. These voluntary fuel standards are developed for residential, commercial, public, community and industrial energy applications. CAN/CSA-ISO 17225-4 standard classifies two grades of wood chips and provides information on the attributes and quality characteristics of wood chips, including origin, particle size, moisture content, ash content, bulk density, etc. Grade A wood chips are suitable for smaller energy systems (provided they meet the equipment’s specifications) used in schools and public and commercial buildings. Meanwhile, Grade B wood chips are better suited for larger systems typical of commercial greenhouses and district energy systems.

Market confidence for wood chip fuel in a growing energy market can be enhanced by better-informed and knowledgeable players who use a standardized technical language. If producers know what fuel quality specifications are expected from wood chip fuel, they can modify and adjust their processes. End users who better understand the supply chain and fuel quality parameters can communicate more effectively with suppliers and procure wood chips appropriate to the specifications of their energy systems.

What is the scope?

The guide applies to small to medium scale heating facilities typical in commercial and institutional buildings (approximately from 75 kW to 1.5 MW) and larger scale facilities such as light industrial sites and district heating (up to 5 MW).

Who is the guide for?

The intended audience for this guide include those involved in:

- Producing and supplying wood chips, including aggregators, sawmills, loggers, urban tree services, woodland management services, value added wood processors such as furniture and cabinet makers, and flooring manufacturers;

- Project developers, including equipment manufacturers, engineering professionals, architects, planning and procurement officers; and

- End-users including facilities managers, maintenance staff and those responsible for the purchase of fuel and operation of biomass systems.

It can also be used as a basic source of information on wood chip fuel for regulatory agencies at the federal, provincial, territorial and municipal levels.

Key features

As a complete knowledge tool for all players in Canada’s wood chip fuel supply chain, the key features of the guide are:

- Practical description of key characteristics of wood chip fuel – provides practical information on the classification of wood chips based on CAN/CSA-ISO 17225-4 and critical fuel properties such as moisture content, ash, particle size, bulk density, chemical elements and calorific value.

- General description of current feedstock and supply of wood chip fuel in Canada – provides details on typical sources of wood chips such as sawmills, logging operations, urban wood and tree services, woodland management operations, aggregators, etc., and practical information on the impact of sources on grading wood chip fuel.

- Recommendations and best practice guidance on wood chip fuel storage and safety for producers – provides practical information on factors affecting fuel quality during storage and recommends outdoor storage of wood chips and roundwood in order to maintain the wood chips’ integrity and minimize potential hazards, such as fire and explosion.

- Recommendations for end users on fuel procurement and storage practices – summarizes key aspects of wood chip procurement and storage practices at end user sites in order to minimize equipment failures due to poor and inconsistent fuel quality, based on best practices, guides and lessons learned from numerous real-life bioenergy facilities.

- Case studies – provides real-life examples of how Canadian producers are perfecting their processes and practices to produce and supply quality and consistent wood chips, as well as lessons learned and adaptations made to resolve challenges.

For those interested in the new Wood Chip Fuel guide, go to store.csagroup.org and use the keywords wood chip fuel, SPE 2254.

The development and publication of the new Wood Chip Guide was completed by the Technical Sub-Committee (under the CSA Solid Biofuels TC) led by CanmetENERGY Ottawa (Natural Resources Canada), M. Douek Consulting, Fink Machine Inc., Ecostrat Inc., Biofuels Consulting, Biothermic Wood Energy Systems Inc., CSA Group, and with funding from NRCan Energy Innovation Program. The authors gratefully acknowledge the financial support from NRCan and in-kind contributions from the lead organizations and other volunteers.

Sebnem Madrali is a senior research engineer with CanmetENERGY Ottawa, Natural Resources Canada. Jaime Fernandez is a project manager, Fuels and Appliances, CSA Group.

This article is part of the Bioheat Week 2023. Read more articles about bioheat in Canada.

Print this page