Don’t Pay for Water

February 24, 2010

By Mark Ryans

One of the hidden enemies of an efficient supply chain is a simple compound: water. Because of the importance of this subject, I will take a couple of columns to cover the topic properly.

One of the hidden enemies of an efficient supply chain is a simple

compound: water. Because of the importance of this subject, I will take

a couple of columns to cover the topic properly.

|

Water occurs primarily within the biomass itself, but in winter, it can

also show up as snow and ice clinging to tops and branches or on top of

uncovered storage piles of comminuted residues. Moisture content is the

single most important quality criterion for forest-origin biomass, yet

we rarely manage it. To put it frankly, moisture content is not managed

because we either don’t recognize its importance throughout the supply

chain or we don’t want to be bothered measuring it. Although attitudes

are changing, harvest residues are often taken for granted and not

treated as a product from the forest.

The most common scenario today is for feedstock payments to be made on

a green tonne basis at the mill gate, thus inciting the supplier to

deliver the material as moist as possible to maximize payload. This

results in paying for excess water, with a negative energy effect and a

less efficient bioenergy system than it should be. On larger-scale

operations, delivered biomass is often stored uncovered for months,

leading to increases in moisture content or losses in dry matter.

Before addressing the management of residues for the control of

moisture, I will introduce why moisture content is important, or more

precisely, why low moisture content should be an objective of any

biomass supply chain. Because most of the biomass used today is for

burning, whether it is for the generation of heat, CHP, or simple (and

inefficient) electrical power, we need to understand that water must be

“burned off” before the energy value of wood is realized. Another

emerging use of forest feedstocks is for pellets. Additional energy for

drying needs to be applied to the feedstock to reduce the moisture so

that the final product from the dies is less than 10% moisture. The

wetter the material, the more heat that is wasted.

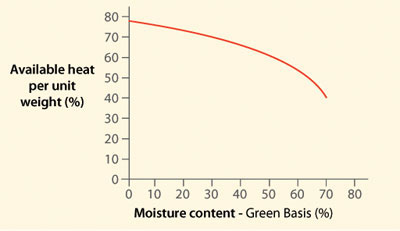

Biomass burners are not all built the same, but they have more-or-less

similar burning efficiency curves (Fig. 1). The burning efficiency,

expressed as the available heat per unit weight at a given moisture

content decreases from a maximum of about 80% at 0% moisture to 40% at

70% moisture content. For example, burning fresh residues at 50%

moisture content would result in a burning efficiency of 61%. The heat

curve drops slowly until about 30% moisture content, rapidly between 35

and 50%, and then dramatically above 55%.

There is also a common misunderstanding that different types of woody

biomass differ in energy content. When expressed on a weight, rather

than volume basis, the energy value does not vary greatly between

species or parts of a tree and only varies by about 10%, from just less

than 19 to 20.5 megajoules/kilogram.

In a simple analogy, you wouldn’t use wet firewood in a wood-burning

stove if you want sufficient heat from it. You wouldn’t pay for green

firewood the same as you would for dry firewood, and if you do buy it

(at a lower price) you would season it before using it the next winter.

Small- and medium-scale boilers require more homogeneous feedstocks

with lower moisture content, so there is ongoing attention to feedstock

quality. Large modern boilers such as those used in Nordic countries

can handle various feedstocks at almost any moisture content, but that

does not mean that excessively wet biomass is acceptable. European mill

managers recognize the value of low moisture content and pay for

biomass on a megawatt-hour (MWh) basis. I am also amazed at how field

practitioners in those countries know the “volume” of a roadside pile

of harvest residues or stumps in MWh content. They don’t talk about

green tonnes. Deliveries are usually monitored for moisture content

using systematic sampling, or volume and weight conversions are used

when shipments from known providers are relatively stable. Under all

approaches, payments for harvest residues are based on energy content,

not green weight.

In my next column, I will show an example of the cost implications of

delivering wet biomass and discuss some approaches to manage the

moisture content of biomass.

Mark Ryans is with FPInnovations’ Feric division and can be reached at mark.ryans@fpinnovations.ca.

Print this page