Dual shaft shredder from Vecoplan

July 12, 2012

By Vecoplan LLC

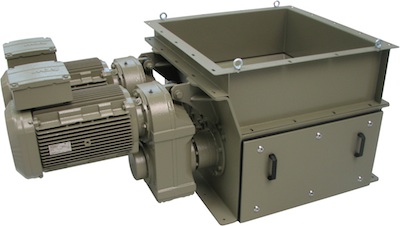

July 12, 2012, Archdale, NC - Vecoplan has introduced their new VNZ 80 XL dual shaft shredder. Known for their single shaft, ram fed, rotary shredders, Vecoplan incorporated two rotors and eliminated the ram in their new VNZ 80 XL.

July 12, 2012, Archdale, NC - Vecoplan has introduced their new VNZ 80 XL dual shaft shredder. Known for their single shaft, ram fed, rotary shredders, Vecoplan incorporated two rotors and eliminated the ram in their new VNZ 80 XL.

But unlike conventional “pierce & tear” dual shaft shredders, the VNZ 80 XL still delivers the numerous advantages inherent to Vecoplan shredders. Plus, the absence of a feed ram provides the VNZ 80 XL with the smallest footprint available on a machine of this performance level.

The VNZ 80 XL continues to produce the consistent shredded particle size that customers expect from a Vecoplan shredder; with the ability to change and control the particle size through quickly and easily changed screens. The two rotors built into the machine are Vecoplan’s patented Torsion Point™ “U” rotors. Rotating at low speeds and high torques, the cutting rotors produce high throughputs at low noise levels and are virtually jam free. Like Vecoplan single shaft shredders, the cutting inserts on the VNZ 80 XL’s rotors are easy to access, are bolt-on so they can be quickly rotated to four points before they need to be changed, and are inexpensive to change when necessary, thereby providing the simple and economical maintenance Vecoplan built its reputation on.

|

|

| Vecoplan's VNZ 80 XL dual shaft shredder. Advertisement

|

Other features shared by Vecoplan single shaft shredders and the VNZ 80 XL dual shaft shredder, include the ability to shred a wide variety of materials and true dump & run operation. Fed from the top via a hopper, entire containers of plastic waste, wood processing scrap, medical waste, paper, cardboard or almost any type of waste can be dumped into the hopper and processed with no further operator interaction.

Vsit our website at www.Vecoplan.com

Print this page