Equipment spotlight: 2018 boiler buyers guide

February 1, 2018

By Canadian Biomass Staff Report

Feb. 1, 2018 - Canadian Biomass takes a look at the newest boiler technology for Canadian customers in 2018.

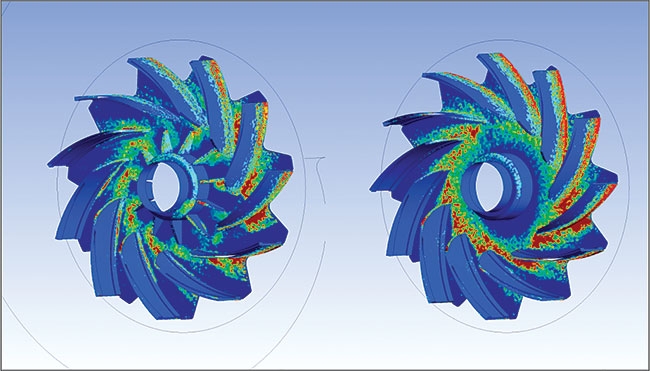

ProcessBarron

ProcessBarron has developed proprietary techniques using computational fluid dynamics (CFD) analysis to “particle-track” the heavier, wear-agent particles in the gas stream. Particles greater than 15 microns are the ones that create the erosion. Using CFD, rotor geometry is augmented or altered to control the path of these heavy particles through the rotor. By minimizing their contact in highly stressed areas of the rotor to eliminate the erosion, a substantial increase in rotor life is possible.

www.processbarron.com

Compte Fournier

Produits Forestier de Petit Paris, a 7.5 MW (25.6 MBTU) boiler installation was the company’s third project using steam energy. Installed in 2016 it was designed to produce five to 16 t/h steam for the dry kiln of the sawmill. It’s the first biomass boiler, which can provide an efficiency superior to 90 per cent using bark with high humidity (greater than 65 per cent). The boiler room consists of a 7.5 MW (25.6 MBTU) boiler that is fed with an automatic moving floor and independent conveyor equipment.

www.compte-fournier.com/en/

Outotec

Turn waste into power with Outotec’s robust waste to energy technology. Outotec’s proven solutions generate valuable energy from variable wastes, ranging from municipal sources such as SRF, RDF, construction and demolition waste, to commercial and industrial wastes and a wide variety of agricultural wastes. The technology works even with difficult fuels, such as those with a high moisture or ash content, and offers the possibility to use fuels over a large range of calorific values, from eight to 30 MJ/kg. Outotec’s technology boasts minimal emissions and low carbon in ash, with over 99 per cent carbon burn-out, and ensures compliance according to local regulations. The system eliminates bottom ash, with only clean, ready-to-recycle, non-combustible material from fluidized bed.

www.outotec.com

Hurst Boiler

Industrial grade wood fired burner with Hurst “clean-burn” stoker design. Modular packages are available from 5 MMBTU/HR to 250 MMBTU/HR with operating temperature ranges from 200 F to 2,000 F. These proven solid fuel burner systems are a leading choice in lumber dry kilns, boiler applications, oil heaters, rotary dryers, brick kilns and more. Hurst manufactures seven different types of biomass stoker/gasifiers, which have used 2,000 plus different types of biomass fuels.

www.hurstboiler.com

Smart Heating Technology

Smart Heating Technology offers highly efficient 93-95 per cent multi-fuel biomass boilers compliant with ASME in Canada. The boilers range from 100 kW to 2,000 kW. Other products Smart Heating Technology offers include: Smart Mobile Micro Cabins 100 – 500 kW; Smart Boiler Cabin Solutions 100-2,000 kW; Special Mobile Cabins incorporating oil/gas boilers; electrical generators; C02 filtration units; hot-air units; and air-conditioning units. The Smart Cabin is a complete plug and play solution. There are also Smart Dryers for wood material, construction material and wheat crop drying, as well as Smart Emergency Energy Cabins for remote locations.

www.smartheating.cz

Jansen

Jansen Combustion and Boiler Technologies, Inc. specializes in improving the performance, capacity, reliability, and safety of industrial boilers that burn difficult fuels, such as biomass, refuse derived fuel, and pulping liquors. Jansen has provided engineering evaluations of over 70 Canadian boilers and has carried out 18 boiler upgrade projects in Canada. Most recently, Jansen has upgraded boiler combustion systems at: CKPI, The Pas, Man.; Harmac Pacific, Nanaimo, B.C.; Daishowa Marubeni, Peace River, Alta.; and West Fraser, Hinton, Alta.; Catalyst, Pt. Alberni, B.C.; Domtar, Windsor, Que.; and Cariboo, Quesnel, B.C.

www.jansenboiler.com

Precision Energy Services

Precision Energy Services (PES) biomass boilers and energy systems convert a plant’s waste into energy. In 2017, PES commissioned the second paper mill sludge-to-energy system for Atlantic Packaging in Toronto. The PES’ fluidized bed boiler system produces 35,000 PPH of steam and hot gas gases to dry 100,000 tons per year of sludge, offsetting natural gas consumption and tipping fees paid for sludge disposal, resulting in a three-year payback. PES supplied the sludge handling system, fluidized bed combustion, boiler system, ash system and gas cleaning system.

www.pes-world.com

Messersmith

Messersmith systems allow a 10:1 turn down ratio. Fuel is moved onto the specially designed grates in the combustor to be burned. The system can burn biomass fuels such as wood chips, sawdust, whole tree chips or other clean biomass with moisture contents from three per cent to 50 plus per cent. High combustion temperatures and PLC control of combustion air results in clean, efficient combustion with low emissions and only a small amount of ash. Messersmith Biomass Boiler Systems are able to deliver hot water, as well as low or high pressure steam, as well as power generation.

www.burnchips.com

Krann

Krann biomass boiler uses a low-emission gasifier/furnace as its heat source. The furnace has a stationary grate with no moving parts. It produces very low particulate emissions, typically with no flue gas cleaning equipment. The flyash accumulation on boiler heat transfer surfaces is greatly reduced thus minimizing equipment cleaning and shutdowns. The system ranges from 1 MW to 15 MW of heat output and can be used for boilers (steam, water, hot oil), drying, CHP, etc., as a cost-effective alternative to traditional wood burners. It can handle a wide range of moisture and ash content fuels. The heating system includes fuel storage, gasifier/furnace, boiler, ash discharge and exhaust and is fully automated.

www.krann.ca

Woodco Energy

Woodco Energy, the Irish manufacturer of biomass boilers, recently launched its Prestige range of pellet boilers in the Canadian market. The boilers underwent UL/CSA accreditation in 2017 and are fully approved for sale in Canada. The prestige is available in 25 kW and 37 kW models. Uniquely the Prestige range can use thermal oil as a heat medium (instead of water) thereby allowing it to be the used with its new co-gen (microCHP) unit. The co-gen can provide up to 10 per cent electricity, so the 25 kW Prestige can provide 2.5 kW electrical power via the co-gen unit. The prestige is also available in a 37 kW model. The company has enquiries from Yukon, N.W.T. and Ontario for Woodco’s co-gen units and CSA approval is likely to be obtained this spring. Cogen will available for sale in Canada immediately thereafter.

www.woodco-energy.com

AFS Energy Systems

AFS Energy Systems recently installed an AFS 600-HP Overfed Reciprocating Grate Stoker steam boiler system with automatic ash removal at the EMD Millipore new central heating plant in Jaffrey, N.H. The system is fuelled by wood chips at a wet basis moisture content of 55 per cent and 600-HP propane boiler system. Included was a dual scrape type fuel bunker receiving, storage and material transfer system with vibrating conveyor with overs screen, permanent magnet, overs belt conveyor and overs grinder.

The system replaced fourteen oil-fired boilers for heating and process loads.

www.AFSenergy.com

Viessmann

The compact Vitoligno 300-C wood pellet-fired boiler is an efficient and environmentally friendly heating solution for residential homes or light commercial applications with up to four boilers in a cascade system. The boiler features an input range of 44 to 193 MBH at a modulation ratio of 1:3, as well as ultra-low energy consumption. Almost everything is automatic – from pellet fuel feed to combustion chamber cleaning and ash removal. The boiler can also be easily converted to manual fuel feed. The Vitoligno 300-C is equipped with state-of-the-art safety mechanisms that ensure close monitoring of the entire system. Modern combustion technology ensures high

efficiency of up to 85 per cent, as well as low emissions that meet the stringent regulations of the European Clean Air Act.

www.viessmann.ca

Fink Machine

With over 100 installations across Canada and into the U.S. Fink supplies high quality CSA and ASME factory certified Viessmann boilers. Fink has experience ranging from small 100 kW single building heating systems to larger multiple building district heating, including a private DH system with 11 clients and 1.5 km of piping. Fink pioneered the use of containerized boiler systems in Canada from shipping containers to custom prefabricated boiler enclosures.

www.finkmachine.com

KMW Energy

KMW Energy Inc. has the expertise to offer complete biomass energy systems for any project including hot water, hot oil, low-pressure and high-pressure steam for power generation. Boilers range in size from 150 HP to 3,500 HP per system and complete power plants are available in the range of 250 kW to 25 MWe. Construction cost and time are kept to a minimum by shop building and shop testing all equipment. KMW’s patented grate system provides the industries best fuel flexibility for utilization of low cost biomass fuels including wet bark, mill sludge, bio solids, and MSW. Recent projects include a 14 MW power plant in Portugal, 150 Million BTU/hr combustion system in Quebec, 8.5 MW CHP plant in New England, 250 BHP hot water boiler in N.S. and 150 BHP hot water boiler in Ontario.

www.kmwenergy.com

Kedel Pellet Boilers

The affordable and reliable Kedel pellet boiler is a fully automated heating appliance that offers 87 per cent efficiency and that can be fully monitored and adjusted from any computer or smartphone. It features a 30-year warranty and its use can result in savings of 20 to 60 per cent on heating costs as well as a carbon footprint reduction of as much as 90 per cent when replacing an oil appliance. This self-cleaning boiler is suitable for new construction or retrofits and can be installed in cascaded designs. Other features include an 02 sensor, 10:1 step-less modulation and a stainless steel burner, and the appliance is manufactured to ISO9001 standards.

www.thsdistribution.ca

Engeman

Engeman boilers have reached a new quality, efficiency and safety level. Engeman boilers are built according to the ASME standard using high-level raw materials and with strict quality. They can produce from 100 up to 2500 BPH of saturated steam at pressures of up to 300 PSI, for several different applications. Engebio boilers can burn woodchips, sawdust, and other kinds of biomass like coffee husks, rice rusks, corncobs, etc. They have heat efficiency between 82 and 88 per cent, low fuel consumption, lower set up cost, are easy to operate and maintain, use a variety of fuels, feature production automation and low emission of pollutants.

www.engeman.ind.br/en

Säätötuli

Säätötuli Canada distributes biomass boilers based on the proven Finnish Säätötuli technology. Single boiler hot water solutions are available from 545,942 BTU/hr (160 kW) up to 5,118,213 BTU/hr (1,500 kW), and hot air furnaces for 1,706,071 BTU/hr (500 kW). Units can be combined to increase output. Automation boxes and pressure vessels are manufactured in

Canada and comply with ASME, CSA and UL. Säätötuli’s efficient burners can process all kinds of solid fuels, including wood pellets, woodchips, hog chips, agro pellets and many more. For wood based fuels, Säätötuli’s equipment complies with all the local emission regulations in Canada. Containerized heating systems also available for easy installation and moving.

www.saatotuli.ca

Andritz

Andrtiz is a global supplier of state-of-the-art plants and equipment for renewable energy generation. The company supplies boilers and gasifiers based on bubbling (BFB) and circulating (CFB) fluidized bed technologies. Plants are custom-tailored to each application, based on capacity, fuel, and customer requirements. The plants are modern, well-proven with over 90 installations globally, and demonstrate unmatched fuel flexibility. Boiler designs include: PowerFluid CFB boilers for up to 800 t/hr of steam generation from biomass such as wood waste, RDF, and other residuals with high calorific value; EcoFluid BFB boilers for up to 450 t/hr of steam generation from biomass such as bark, sludge, rejects, and other residues.

www.andritz.com

SolaGen

SolaGen has the versatility to offer combustion systems that can utilize any available fossil or biomass fuel: dry, wet, or densified. These systems are designed and manufactured “in house” and therefore are perfectly matched to SolaGen’s rotary dryers, steam and hot water boilers, thermal oil heaters, or other process heating systems. Energy output capacities from 50 kW to 93 MW per hour have been supplied to a variety of industries.

www.solageninc.com

Evergreen BioHeat

Evergreen BioHeat Ltd. is Canada’s distributor of Fröling biomass heating units. It carries the S3 (logwood), P4 (pellet), T4 (pellet and woodchips) and industrial sized TM (pellet and woodchips) boiler lines from 8 kW through to multiple MW commercial installations. The new T4 can efficiently burn both wood chips and pellets due to its intelligent fully-automatic system. The T4 ensures a high level of efficiency (up to 94.6 per cent) with very low emissions. Well-planned use of energy-saving drives ensures extremely low energy consumption.

www.evergreenbioheat.com

Binder

Binder Energietechnik GmbH has produced large-scale biomass boilers ranging in power from 100 kW – 20,000 kW at its production facility for more than 30 years. About 200 boilers are manufactured each year at the Binder factory in Styria, Austria. In addition to higher operating pressures as well as different insertion and installation situations Binder provides an optimum solution for your requirements. Binder also offers a variety of combustion systems for a wide range of fuels like cherry pits, chicken litter, cacao shells and much more. All boilers are designed and manufactured according to current standards. For international markets like North America and Canada, Binder offers ASME compliant boilers.

www.binder-gmbh.at/en

beloTEQ

beloTEQ specializes in the conception and setup of bioenergy turnkey projects ranging from 200 kW to 6 MW with a variety of fuels. beloTEQ believes that our society’s prosperity implies energy independence and development of locally available renewable energy sources. beloTEQ’s team provides technical services in many areas related to bioenergy projects. Whether it is for a feasibility study, the technical design of projects, the design of sub-components or the technical evaluation of existing projects, beloTEQ can be of assistance. beloTEQ believes in the strength of a team and has developed partnerships with Uniconfort, a European leader in the production of biomass boilers.

www.beloteq.com

This article is part of the Bioheat Week 2023. Read more articles about bioheat in Canada.

Print this page