Eyeing the bioeconomy: Fibre solutions, innovation, and support for First Nations in B.C.

May 2, 2023

By Catherine Nutting

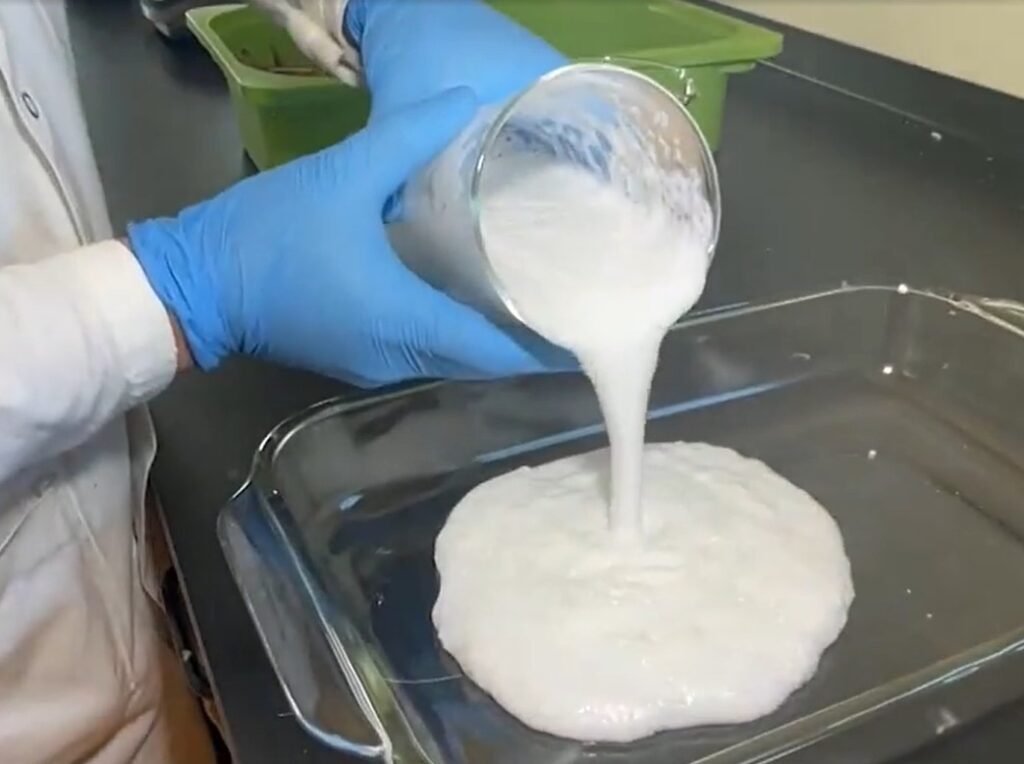

Biofoam production. Photo courtesy Innovation, Bioeconomy and Indigenous Opportunities Branch of the B.C. Ministry of Forests.

Biofoam production. Photo courtesy Innovation, Bioeconomy and Indigenous Opportunities Branch of the B.C. Ministry of Forests. Since 2019, the British Columbia Ministry of Forests has been at the forefront in supporting Indigenous-led forest bioeconomy projects through its Indigenous Forest Bioeconomy Program (IFBP). The IFBP provides funding and technical support to Indigenous project partners that seek ways to maximize the use of forest biomass through the potential commercialization of new bioproducts as well as the development of novel ways to derive social, environmental, and economic value from our forests. We endeavour to promote a healthy forest bioeconomy, defined as an economy based on the use of forest biomass as the main input in the production of bioproducts, consumer goods, or industrial products, with the effect that petrochemical-based products become relatively displaced from the economy.

The IFBP engages with Indigenous communities to identify and collaboratively develop project plans, creating bioeconomy opportunities and the capacity for scalability, and fostering Indigenous entrepreneurship in the natural resource sector by prioritizing clean tech and sustainable resource management. The IFBP supports Indigenous communities’ ownership of or participation in projects related to B.C.’s forest sector, particularly targeting initiatives that pertain to advanced bioproducts over conventional forest products. Innovative projects supported by the ministry include replacing bitumen with lignin in asphalt, prototyping a bio-based packaging material as an alternative to synthetic packing foam, and considering various applications for nanofibrillated cellulose, to name a few. In terms of fibre supply, IFBP has supported biomass supply and processing analyses, fibre use feasibility studies, assessment of forest residuals as supplies for processing, and the development of forest-based bioproducts.

IFBP funding takes a phased approach to project support, and we communicate closely with the applicant as they promote and describe their longer-term project goals. An Indigenous partner’s application often begins with scoping (product research, market research), feasibility studies, testing (prototyping, piloting), and validation (performance assessment, market validation) before moving on to proof of concept and commercialization. In this way, the program can support the partner at any stage of the project/product development. The IFBP is guided by the Indigenous Forest Bioeconomy Framework co-developed with the input of First Nations across the province, which aims to foster Indigenous community and business driven projects that meet community needs while furthering regional economic development opportunities.

Recent projects

Projects eligible for IFBP funding have the following qualities: they use the forest biomass; they are located in B.C.; they are supported by the applicant community; and they are economically, socially, environmentally, and culturally beneficial. These projects respect and support Indigenous community cultural values and traditions, establish or expand self-sustaining businesses, and address gaps in B.C.’s forest bioeconomy, often by maximizing the forest biomass value in innovative ways. As well as financially supporting projects that assess and utilize wood fibre, the IFBP also funds research into maximizing the use of residual wood that would previously have been considered waste.

In terms of non-timber forest products, IFBP support for research into and/or market development has included birch water, big leaf maple syrup, essential oils derived from forest flora, and the extraction of tannin from coastal wood residuals.

Great Bear Rainforest Essential Oils. Photo courtesy Innovation, Bioeconomy and Indigenous Opportunities Branch of the B.C. Ministry of Forests.

In terms of projects that relate to fibre supply, we have developed bioeconomy road maps to help Indigenous partners quantify potential fibre supplies and the emerging opportunities that exist in their traditional territories, estimated log supplies and post-harvest wood residuals, and suggested methods for improved productivity and new revenue streams. Recently the IFBP has funded modelling of biomass availability and fibre supply analyses, and has tested the use of wood residues in the manufacture of pressed D-logs. We have provided technical descriptions and cost estimates to consider creating a centre for biomass fuels for various types of biomass heating systems. For a Nation who does not have forest tenure but who was considering purchasing logging residuals, we funded a cost/benefit analysis related to the possible purchase of a wood chipper. For an applicant who was looking into the potential development of a dry kiln and biomass boiler, we funded an analysis of the next steps in establishing a viable biomass supply chain, which recommended investing in an area to accommodate the longer-term storage of biomass. Another Nation has created a “virtual forest” through IFBP funding of a biomass assessment method that correlated canopy loading data with upward-oriented photos.

Novel projects arise in response to the decreased availability of fibre. For example, the IFBP has supported projects related to the use of commercially thinned trees, and has investigated the efficacy of smaller-scale chippers. We have funded market and economic analyses to create specialty mills in response to changes in timber availability. One Nation applied for assistance to transition from harvesting large-diameter to small-diameter trees. Another required research into options for milling misshapen trees. Recently, the IFBP has supported a venture that manufactures engineered wood products from wood that was killed by pine beetle infestation and wildfire.

Pressed D-logs from Deadwood. Photo courtesy Innovation, Bioeconomy and Indigenous Opportunities Branch of the B.C. Ministry of Forests.

Fibre supply hurdles and responses

An inability to access adequate fibre is one of the biggest issues many Indigenous forestry enterprises face. Small-scale businesses and First Nations entrepreneurs can be hampered by the lack of access to primary processing facilities, not having timber licenses, or finding it difficult to access residual fibre scattered in the forest post-harvest. Mill closures have led to decreased availability of post-processing wood residuals, while the use of those forest-based materials that do exist can be hampered by the distance between manufacturing centres. The provincial government noted that in 2019 most large forestry companies in the B.C. Interior curtailed sawmill volumes, due to high log costs, border tariffs, reduced demand, and issues of accessing timber. Susan Yurkovich, past president and CEO of the B.C. Council of Forest Industries, has noted the critical importance of dependable fibre supplies. Yurkovich enthused, “B.C. has great people, great fibre, and the expertise, knowhow, and technology to be the preferred supplier of low-carbon, sustainably managed forest products that will fight climate change,” but she noted the importance of policy that creates predictability, encourages innovation, and promotes reinvestment.

In 2020, the Province issued Modernizing Forest Policy in British Columbia, which laid the foundation for the further development of policies and initiatives aimed at creating added value; making fibre use sustainable; promoting emerging bioproducts; and creating a collaborative, transparent landscape planning process. Dan Battistella, former president of Interior Lumber Manufacturers’ Association, called the policy “a move to a more value focus with more community involvement.”

Measures aimed at increasing fibre supply will involve reviewing issues of forest tenure distribution, enhancing oversight for log exports, and considering timber sales methods that can allow for smaller volume sales to value-added manufacturers. The province hopes to increase the amount of replaceable forest tenure held by First Nations in order to increase the participation of rural communities, to foster employment, and to ensure that fibre is utilized. To make fibre use sustainable and predictable, the province has committed to distribute harvesting more evenly on the landscape, review the cut control process, support value-added manufacturers, and increase silviculture and innovation investments.

Moving forward – innovating

Because of the current lack of fibre, B.C. needs to derive greater value from the timber harvested and the fibre produced. In order to have a diversified forest sector that can weather global fluctuations in forest product pricing, we need to innovate to create new products and to build international linkages.

B.C. can learn from other regions. In China, forest-grown beverages, spices, and medicines are a stable, large export, with mushrooms being their fourth largest plant export. We need to keep an eye on the international environment so that we can prepare now to be able to engage with changing international supplies of fibre in the future. For example, 65 per cent of China’s total forest is currently assessed as immature, leading to questions about how its eventual maturation will affect B.C.’s ability to sell or to purchase fibre.

For B.C.’s forest sector, besides increasing capital investment and labour productivity, investment in research and development is crucial. The Ministry of Forests recently funded research that evaluated high biomass volume concrete mixes for building structures fabricated through a 3D printing process. The study found that 50-75 per cent of the total volume of the concrete mix used in 3D building construction could derive from wood-based biomaterial.

Another emerging area that the ministry is investigating is wood-based textiles, which are expected to expand extensively in the next ten years, with Brazil and Indonesia currently identified as possible market leaders. At present, dissolving pulp is the main raw material for wood-based textiles, although more efficient methods are being developed. Research recommends designing or converting pulp mills into “swing mills” that can flexibly change between textile and paper pulp production depending on the market. Because of the positive correlation between textile fibres and the production of sawn wood, and because of the positive role to be played by wood-based textiles in a circular bioeconomy, this favours the establishment of bio-hubs where wood-based textile fibres can be produced in proximity with products made from long-lived solid wood.

Bio-hubs, or bioeconomy clusters, are one of the key new opportunities for enhancing fibre supply, and are a subject of important ministry-funded research. In the past ten years, bioeconomy clusters have been founded in Europe, with Finland being a leader. Finland’s bioproduct plants demonstrate how economically sustainable this kind of work can be – they produce pulp, electricity, and chemicals, without the use of fossil fuels, and with greater efficiency than traditional pulp mills. Currently in B.C. there are opportunities to co-locate advanced biomaterials facilities with existing infrastructure: for example, a pulp mill can support a lignin extraction facility and a cellulose facility.

The ministry-supported research into these bioeconomy-clusters found that their longevity depended more on support for piloting, networking, infrastructure, internationalization, and contact with academic research institutes than on subsidies, although financial assistance was important in the set-up phase. This research also argued that funding of such clusters should be directly tied to a participant’s willingness to engage in cooperation and consortiums, since that proved to be the lifeblood of successful clusters. Other key factors included making the project market-driven, and determining the value chain from raw material to end user before the inception of the cluster. When local forest biomass becomes the input for a range of bioproducts, this sustains regional economies and provides jobs and entrepreneurial opportunities for rural and Indigenous communities.

In order to increase fibre access for value-added domestic manufacturers, the province intends to minimize the burning of post-harvest slash piles so that this fibre is available for manufacturing; to link a focus on the value-added sector to timber sales programs; and to look into how best to support value-added business, both in traditional remanufacturing processes and in innovative products. Targeted research programs are also needed, to address specific industry needs, to discover ways to increase the biomass content in conventional products, and to address the complex questions related to fibre supply. IFBP, committed to working closely with First Nations to respond to emerging goals, will continue to play a role in researching and fostering Indigenous forest bioeconomy projects.

Catherine Nutting is an Indigenous bioeconomy policy analyst with the Innovation, Bioeconomy and Indigenous Opportunities Branch of the B.C. Ministry of Forests.

Print this page