Fibre pile management best practices

June 23, 2021

By Michele Fry

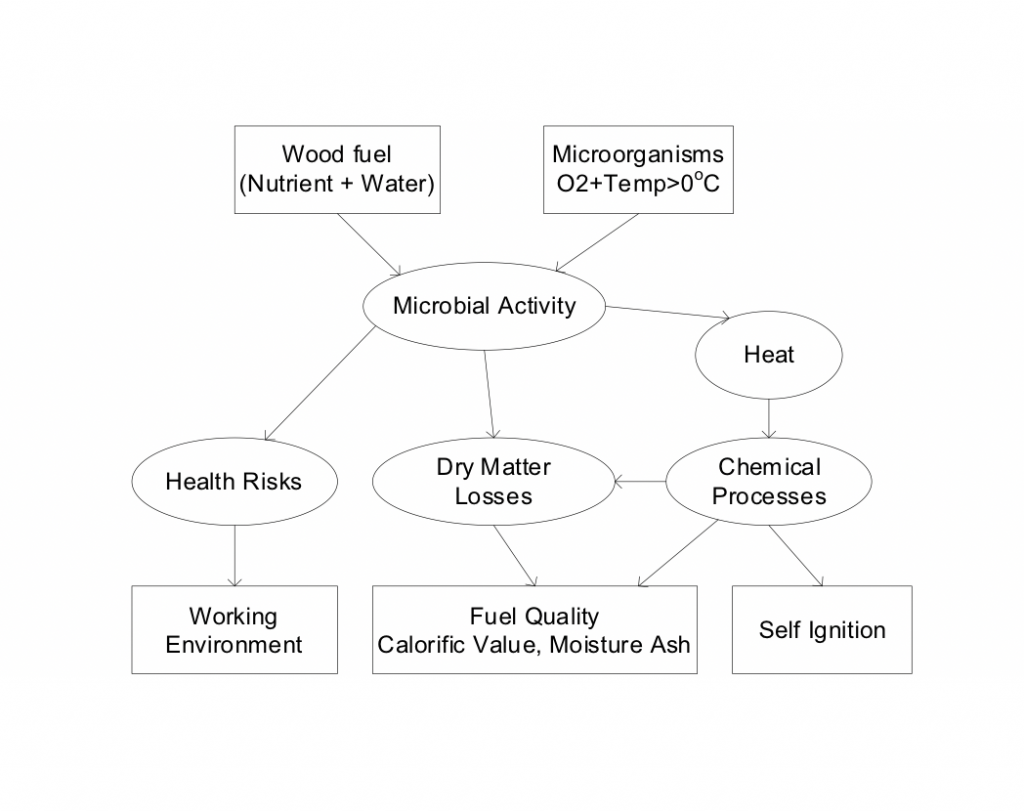

Figure 1. Source *Best Practices in Fibre Pile Management

Figure 1. Source *Best Practices in Fibre Pile Management Wood fibre manufacturing dedicated to biomass fuel production such as wood pellet manufacturing uses industrial waste products such as hog fuel or wood chips from lumber mills, pulp and paper mills, wood products manufacturing and more to create their fuel products. Traditionally, these waste products are stored in large fibre piles at manufacturing work sites. If not managed correctly, the accumulation of wood fibre in piles can pose a significant fire risk. These piles contain materials that consolidate and pack together. The range of moisture content combined with various particle sizes and densities within the material leads to microbial growth and biological activity. The combination of these factors can cause the fibre piles to self-heat over time due to the microbial decay of the wood fibre, triggering combustion within the pile(s).

The hazardous result of this biological, physical and chemical reaction generates smouldering pockets that can endure continuously for months, creating gaps and fire pockets that can collapse under any weight. These smoulders can even lead to surface fires and open flames when exposed to oxygen such as wind, exposure from another fire or from other ignition sources close to the piles.

Effective management of wood piles and good safety planning can help decrease the risk of internal fires caused when fibre piles self-heat, causing combustion. The risk of spontaneous ignition increases if the raw material or solid biofuel is initially moist, the stored volume is large and the ambient temperature is high. Follow the best practices in fibre pile management and control methods below developed by *Shahab Sokhansanj, Ph.D., and *Fahimeh Yazdan Panah, Ph.D., to help mitigate the risks of spontaneous fibre pile fires to help keep workers safe and your fibre protected.

Storage

- Fibre pile storage should preferably be located on dry, level ground on an asphalt or concrete surface close to the transport road

- The dry, level ground should be free of stumps, stones and large residues

- The storage area should be located in an area higher than the transport road(s) to avoid rainwater saturating the storage pile from the water accumulating on the road(s)

- Outside storage piles should preferably be covered to avoid precipitation or the accumulation of moisture

- Store dry fibre piles (<20 per cent moisture content) to avoid microbial growth

- Different types and qualities of fibres, such as hog fuel and wood chips, should never be mixed and should be stored separately

- Fibre piles should preferably be stored in small piles

- Store fibre piles for a short period of time

- Ensure fibre pile storage management controls are in place with inventory and timeline management as essential control measurement

- Store the material such for FIFO (First In-First Out)

- Avoid compacting the material – (i.e.) running heavy equipment on the material

- Use these rules of thumb:

- FIFO (First In-First Out): store the material to ensure it is transported first in-first out to reduce the risk of some material sitting in the pile for an extended period of time

- Raise piles in elongated stacks using this rule of thumb: base width twice the height of the stack

- Fibre pile typical heights:

- clean wood chips without bark: 15 metres,

- chipped forest residue: 15 metres

- bark: seven metres

- sawdust: six metres

Control measures

- Use a Forward Looking Infrared (FLIR) camera or thermal imaging camera to identify hot spots early

- Monitor the temperature at several different locations in the bulk

- Measuring the CO concentration in the air above the fuel surface is one possible method for detection of activity in the fuel bed

- Other detection methods include multi-gas detectors and sensitive “electronic nose” detectors

- Understand the signs of an on-going self-heating process to detect the hazard – the first sign is often a sticky and irritating smell

- Initiate firefighting if the smell or sight of fire is sensed from the storage pile such as the smell or sight of smoke (not steam or water vapour) or if flames or embers are spotted. Use trained fire fighters or contact the local fire department to safely expose and extinguish fibre pile smolders/fires.

- Ensure workers do not climb up on and equipment does not scale or drive on a fibre pile that is suspected of self-heating

- Restrict public access to fibre storage areas

- Follow all established safe work procedures regarding fibre pile storage

- If you suspect the pile is self-heating

- Don’t go on top; instead, seek help and advice from your supervisor

- Check to see if your safe work procedures follow a process; if there is no procedure in place, ask your supervisor for help

To learn more about fibre pile management, visit the Wood Pellet Association of Canada

Resources:

BCFSC Fibre Pile Management Crew Talk

WPAC Safety Alert: Fibre Pile Fatality

*Dr. Shahab Sokhansanj (PhD, MSc) is an Adjunct Professor of Chemical and Biological Engineering at the University of British Columbia Faculty of Applied Sciences

*Dr. Fahimeh Yazdanpanah (PhD, PMP, P.Eng) is the Research and Technical Development Director for the Wood Pellet Association of Canada, founder of Spark Biomass Consulting Inc. and former Research Associate in Biomass and Bioenergy Research Group (BBRG) at the University of British Columbia.

Michele Fry is the director of communications for the BC Forest Safety Council.

Print this page