Impact cradles control spillage, preserve belt integrity

April 2, 2015

By Martin Engineering

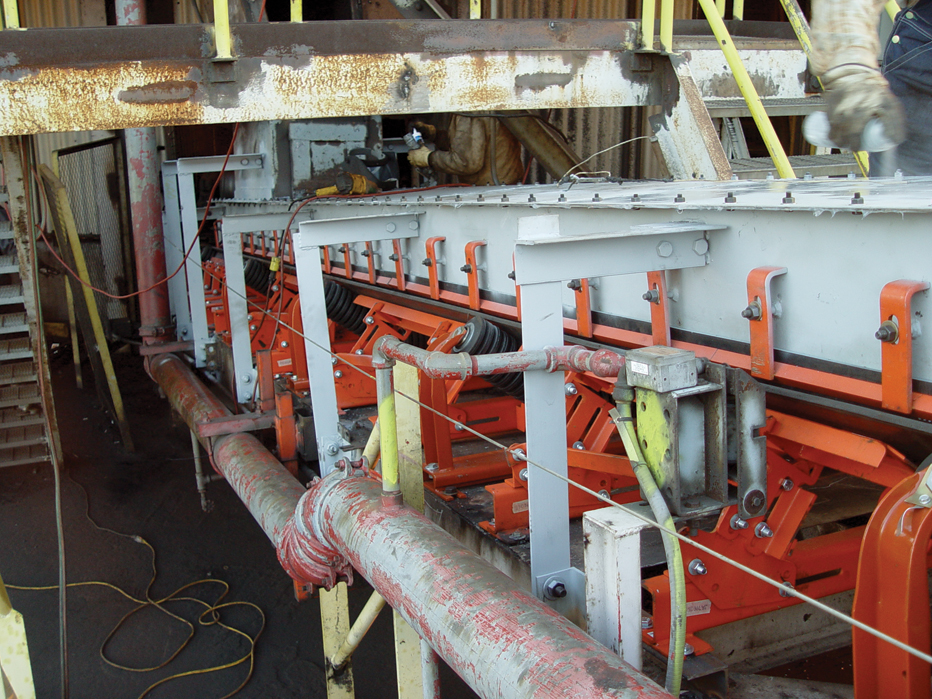

April 2, 2015 - Martin Engineering’s Heavy Duty (HD), Medium Duty (MD) and Light Duty (LD) Impact Cradles feature a bed of steel angles lined by energy-absorbing impact bars with a top layer of low friction, ultra-high molecular weight (UHMW) plastic.

The cradles are designed to be located at transfer points of receiving conveyors, under the hopper and chute box, close to the tail pulley. Depending on the force of the discharged material, they can possess different structural qualities. All three Martin Impact Cradles feature wing supports, which adjust to match CEMA standard trough angles, as well as a five per cent fine-tuning adjustment angle. This allows for the cradle to accommodate the idler profiles of different manufacturers.

The Martin Impact Cradle HD is designed to withstand impact forces from 12,000 to 17,000 lbf. (53.4 to 75.6 kN) and drop heights of light material up to 50 feet (15.2 m). Classified as Heavy-Duty (H) in CEMA Standard 575-2000, it fits E-6 and E-7 conveyor configurations. Support beams in the centre of the cradle are set 3/4″ (19 mm) below the receiving belt’s line of travel, allowing the belt to avoid sustained friction when running empty, yet absorbing significant impacts during loading while still retaining a tight seal.

The unit is equipped with 7 to 13 heavy-duty impact bars, depending on width. Installed perpendicular to the belt path, the bars are reinforced by a steel support structure with a base of impact-absorbing 50-durometer styrene-butadiene (SBR) rubber and a top layer of slick UHMW plastic. They are engineered to withstand dynamic energy and a heat range of -20° to 140°F (-29° to 60°C) without compromising the structural integrity of the conveyor frame. The cradle is on a Trac-Mount, allowing it to slide out for bar replacement

The Martin Impact Cradle MD is designed for medium duty applications, suitable for use with belts traveling up to 1,000 ft/min (5 m/s). Mounted on four steel I-beam supports, the cradle is able to sustain a maximum weight of 12,000 ft/lbs (53.4 kN) with light material drop heights up to 26 ft. (7.9 m). Classified as Medium-Duty (M) in CEMA Standard 575-2000, the unit is available for belt widths from 24″ to 72″ (500 to 1,828 mm).

Depending on width, the MD Cradle is fitted with 6 to 16 impact bars. They are composed of an aluminum T-slot surrounded by energy absorbing 83A-durometer urethane, coated with a layer of low-friction UHMW plastic, which prevents belt fraying while retaining a tight seal at operating temperatures of -20° to 180°F (-29° to 82°C). Each bar is reinforced by a bed of steel “wing” supports, which can be adjusted to match any CEMA standard trough angle, with five degrees of wear adjustment.

The MD model is built to withstand a weight of 90 pounds (40.8 kilos) dropped from a 10-foot height.

The Martin Impact Cradle LD conforms to CEMA No. 502-1998 & 575-2000, but the Class L design is made for lighter materials with impact forces that could still affect the belt and conveyor over time. Utilizing the same impact bar technology, it is able to withstand a maximum weight of 8,500 ft/lbs (37.8 kN), equal to 50 pounds (22.7 k) being dropped from 10 feet, with light material drop heights of up to 12 ft. (3.6 m).

Mounted on three steel channel beams, the LD is available for belts from 24 to 48 inches (610 to 1219 mm) wide, with 6 to 10 impact bars. The unit controls the spillage of dust and fines at belt speeds as high as 1,000 ft/min (5 m/s).

For more information, visit www.martin-eng.com or call (309) 852-2384.

Global representatives for Martin Engineering can be found at www.martin-eng.com/rep-finder.

Print this page