KLM, Neste and CFM International test aircraft engine running on 100% SAF

February 27, 2023

By KLM Royal Dutch Airlines

Engine test run of SAF. Photo: KLM Royal Dutch Airlines.

Engine test run of SAF. Photo: KLM Royal Dutch Airlines. Early this year, KLM Royal Dutch Airlines partnered with engine manufacturer CFM International and fuel producer Neste to conduct a test using an aircraft engine running on 100 per cent sustainable aviation fuel (SAF). Data analysis has now confirmed that 100 per cent SAF can be used safely. The test has generated new data that can be used to set further specifications for SAF. This test is a small, but significant step towards making the airline industry more sustainable.

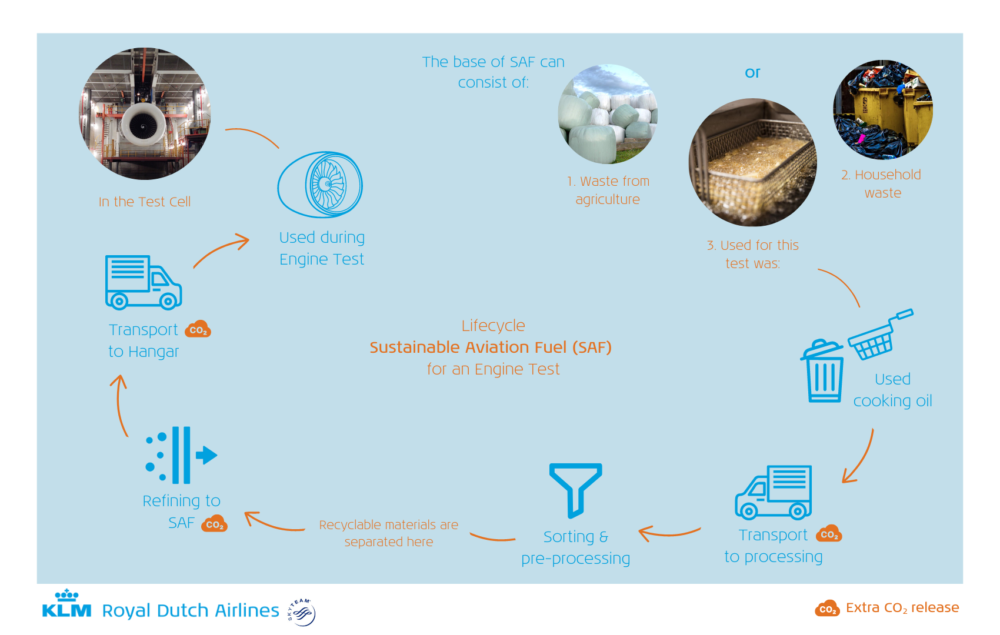

The engine for the test (a CFM56-7B) was provided by CFM International, while Neste supplied the SAF, which is produced from used frying oil.

Research during engine test

The test took place in KLM Engineering & Maintenance’s test cell at Schiphol-East, where test runs with aircraft engines take place. A test run is conducted after maintenance is completed to guarantee airworthiness. The first round of the test was powered using standard fuel and the second using 100 per cent SAF. Extensive inspections and checks were carried out on the engine during and after the test run.

Along with other data, the engine’s pressure and temperature were measured during the test. These values indicate how efficiently the engine handles the fuel and its effects on various components. By comparing the two test rounds, KLM can gain greater insight into the engine’s performance running on 100 per cent SAF. The test was completed successfully and represents a step closer to flying on 100 per cent SAF.

Gaël Méheust, president and CEO of CFM International, said, “We’re excited to be part of this important project. As an engine manufacturer, we’re constantly working on advanced technologies for a more sustainable future, but using SAF is something we can do right now. Our hope is that these tests will pave the way for regulatory approval of 100 per cent SAF across the board.”

Sustainable aviation fuel

The SAF used for the test was HEFA-SPK, made from used cooking oil. The main advantage of SAF is that it emits less CO2 over its entire lifecycle than regular fuel. Over its lifecycle, the SAF purchased by KLM ensures a 75 per cent reduction at least. SAF’s potential could be far greater at around 85 per cent with today’s technology. This could grow to 100 per cent in the future.

SAF is currently approved for use in all aircraft, but only in blends of up to 50 per cent with conventional jet fuel. The use of 100 per cent SAF in aviation has not yet been approved and requires certain specifications, which can only be determined on the basis of extensive research and data. Engine tests like this contribute to this research. Since January 2022, KLM has been blending in 0.5 per cent SAF for flights departing from Schiphol. Customers themselves are also given an opportunity to voluntarily add extra SAF when purchasing their tickets.

Jonathan Wood, vice-president Europe, renewable aviation Neste, said, “Sustainable aviation fuel plays a crucial role in reducing CO2 emissions from aviation. Tests like this by KLM with Neste MY Sustainable Aviation Fuel represent an important step towards 100 per cent SAF certification, because it demonstrates that 100 per cent SAF can be used safely. Neste co-operates closely with partners such as KLM and CFM International to accelerate the transition to SAF as we increase our SAF production capacity to 1.5 million tonnes per year by the end of this year.”

Ton Dortmans, EVP KLM engineering and maintenance, said, “We’re proud of the engineering and maintenance team and grateful for their commitment to this project. Engine tests like this help KLM to learn more about using SAF and making our industry more sustainable. The test contributes to KLM’s goal of being CO2 neutral on the ground by 2030. The Engineering & Maintenance division hopes to be able to test using 100 per cent SAF by then. KLM E&M is of course thrilled to have taken this first step in co-operation with Neste and CFM International.”

The future of SAF

SAF is not yet widely available. KLM is committed to scaling up the production and use of SAF to achieve greater sustainability in the future. KLM is cooperating with various parties to research and develop all possible technologies, and to encourage scaling up the production facilities. Two major purchasing agreements were signed recently with Neste and DG Fuels.

Print this page