Local wood pellets driving GHG reductions in New Brunswick

March 20, 2023

By Wood Pellet Association of Canada

King Street Elementary School: An interview with facilities manager Ronald Lavigne.

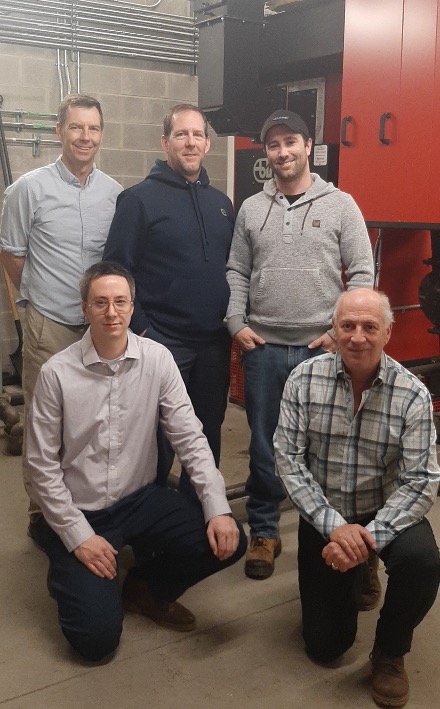

Local pellets lower GHG emissions at King Street Elementary School in Miramichi, N.B. The team at the school say the biomass boiler system is efficient and easy to use. In the photo; bottom right Ronald Lavigne (facilities manager), bottom left Andrew Underhill (assistant facilities manager), top left to right, Chris MacDonald (custodian II, King Street Elementary), Mike Keane (MRIII, millwright) Justin Fogarty (MRIII, HVAC technician). Photo: WPAC

Local pellets lower GHG emissions at King Street Elementary School in Miramichi, N.B. The team at the school say the biomass boiler system is efficient and easy to use. In the photo; bottom right Ronald Lavigne (facilities manager), bottom left Andrew Underhill (assistant facilities manager), top left to right, Chris MacDonald (custodian II, King Street Elementary), Mike Keane (MRIII, millwright) Justin Fogarty (MRIII, HVAC technician). Photo: WPAC The Government of New Brunswick is leading the way in promoting sustainable building practices. One of the key goals of the government is to lower energy consumption in turn reducing greenhouse gas emissions and providing cost savings for the people of New Brunswick – and local wood pellets are increasingly being viewed as part of the equation.

One such example is the King Street Elementary School in Miramichi, N.B., which was the province’s first venture into version 4 of the Leadership in Energy and Environmental Design rating system. The LEED v4 standard was used to guide the construction of a highly energy-efficient school that also emphasizes human health and well-being. The two-storey school designed by Boyd R. Algee Architect Ltd., was built in 2017 covers 6,137 square metres, can accommodate about 400 students, and features a biomass boiler for its heating needs.

Fast forward five years – we wanted to see how the boiler system is performing so we caught up with Ronald Lavigne, and electrician by trade, who has worked in the school district for nearly 30 years and today is the facilities manager for 29 schools and three educational centres in the Anglophone North School District, which includes the King Street school. He was also part of the team that worked with the Department of Transportation and Infrastructure (DTI) for the design concept of the school.

Many people don’t often think about the role that boilers play in sustainable design; how did the decision to go to biomass come about?

I would like to say I was instrumental in being part of the decision to go biomass, but I wasn’t. With that said, I had worked at the Hotel Dieu Hospital before it was closed, and I saw firsthand the value of a biomass system. When I was informed that there was going to be a biomass boiler installed at the King Street School, I was very pleased.

What were your perceptions about wood pellet boilers before the project? How has that changed now after five years with the equipment?

There were many who questioned this type of system and said it would not work and would be high maintenance. Well, it does work and very well with little maintenance. The sceptics were wrong.

What were your learnings along the way with installation? With actual running and maintenance?

Our team was kept up to date each step of the way during the installation of this heating system. We were well informed as to what was required to operate this system and all the maintenance procedures that would be needed to achieve longevity of this system.

Tell us about the wood pellet system – how it works, is it easy to run/maintain?

I have one maintenance person assigned to this system who has a great passion to keep this unit as well maintained as possible. The system requires very little hands-on operation and runs like a clock. The only downside I can say is that we do not have full access to the software remotely, but we have adapted to that and are managing fine.

New Brunswick has cold winters; how does the biomass system perform?

The interesting thing we see with our system is that it can maintain the heat demand even on the coldest days.

One of the goals of the government’s Green Building Policy is to, whenever possible, use materials that are manufactured close to the construction site to minimize the energy used to transport them. How was this achieved with wood pellets?

It was easy. We purchase our pellets locally from Groupe Savoie’s pellet plant 250 kilometres away. The fibre used from the pellets is also local – from nearby harvest and sawmill residuals that normally would have been burned or in the past put in landfills. Last year, we purchased 67.33 metric ton of pellets – all of it local. The pellets are delivered straight to the school.

The school has propane boilers as back up; have you had to use them very often?

It is very rare to see the propane boilers come online. We do test them periodically to make sure they are functioning properly.

From the outset, one of the goals was to install a system that reduced greenhouse gas emissions (GHGs) versus propane – has this been achieved?

Yes! Using wood pellets instead of propane in the 2021-22 school year resulted in 74 metric tonnes of carbon dioxide (MTCO2) being avoided. In fact, since the school was built more than 488 MTCO2 of GHGs have been avoided, that’s the equivalent of planting 8,060 trees.

What advice would you have for others contemplating new heating systems for schools, hospitals, and other commercial or institutional buildings?

I would highly recommend that they consider installing a biomass system.

You can learn more about commercial and institutional use of local biomass at pellet.org or read the case study at the Collège communautaire du Nouveau-Brunswick (CCNB) and the Université de Moncton (UDM) at the CCNB-UDM Shippagan Campus.

Print this page