Lube saves 10% in biofuel manufacturing

March 10, 2012

By

Scott Jamieson

March 10, 2012, London, UK - Scientists at Imperial College London have demonstrated that a key part of biomass processing could be made 80 per cent more energy-efficient by taking advantage of the slippery properties of fluids called ionic solvents.

They say this could reduce the cost of biofuels by 3p per litre, around

10% of its current cost. [1]

The efficiency savings can be made

during one of the energy-intensive stages of the biomass manufacturing

process, when solid timber chunks are turned into a 'soup' of fluids and fine wood particles

in an industrial grinder, which works in a similar way to a giant

coffee grinder. The discovery paves the way to making the biomass

industry greener.

Treating timber with ionic solvents has

previously been shown to help processing wood into biofuels and

chemicals. While initially this effect was only attributed to the

solvents' ability to partially weaken wood's tough, fibrous structure,

this new study suggests the energy-savings are predominantly due to the

way that these fluids lubricate the wood chips as they go around in the

grinder.

Lead author of the study Dr Agnieszka Brandt, from the

Department of Chemistry at Imperial College London, said: "Tree wood is a

mine of really valuable chemicals locked up in a safe that we need to

unlock before we can use the different components. Breaking down the

timber into a fine powder helps us to access these chemicals, but it

needs to be an energy-efficient process to make it sustainable. Our

previous work showed how the chemical action of ionic solvents improved

energy efficiency in the processing, but we were surprised to discover

how much more energy could be saved when take advantage of their

lubricating physical properties."

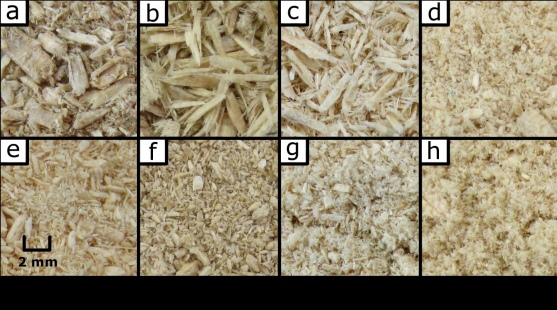

Photographs of ground wood chips after treatment with various ionic solvents and liquids [2]

'Green'

biomass products are often hailed as environmentally friendly

alternatives to fossil fuel and its derivatives. Trees such as fast

growing species of willow and pine will be an important source of

biofuels and basis for manufacturing naturally occurring chemicals like

vanillin (a flavouring in the food industry), valuable oils and

biomass-derived plastics, such as polystyrenes or polyesters (used for

plastic bottles). Scientists are working to ensure biomass lives up to

these expectations, assessing and reducing the environmental impact of

every part of the product cycle, including the source of its raw

materials, how and where they are transported, and what happens to the

by-products of the industry.

Research author Tom Welton, Professor of Sustainable Chemistry

and Head of Imperial’s Department of Chemistry, said: "Sustainable

development has been defined by the UN as development to meet the needs

of the present generation without compromising the ability of future

generations to meet their own needs.

"The alleviation of poverty

and improvement of all of our living standards cannot continue without

us also ensuring that our planet is in a condition to support these. As

our petrochemical resources run out and we need to turn to other places

for our energy and materials needs, we have an opportunity to build

these new industries in a sustainable way. This is an opportunity that

we can’t afford to miss."

Notes

[1] Calculating the cost-saving in biomass manufacturing

- The estimated grinding cost of grinding biomass is £8 per tonne. This method would reduce that by 80%, which is £6.40/tonne.

- Each tonne of biomass produces about 200L of ethanol

- This is a saving approximately 3p per litre off the cost of ethanol

- Ethanol costs just about £0.30 per litre, so this reduces prices by ca. 10%

[2] Photograph shows ground wood

chips after treatment at 90 °C for 1 h with various ionic solvents and

other liquids: (a) no liquid, (b) Organosolv, (c) DMSO, (d) silicone

oil, (e) [C4C1im][HSO4], (f ) [C4C1im][MeCO2], (g) [C4C1im][NTf2], (h) Fomblin.

Print this page