New report on deflagration isolation released

January 11, 2022

By Gordon Murray, Executive Director, WPAC

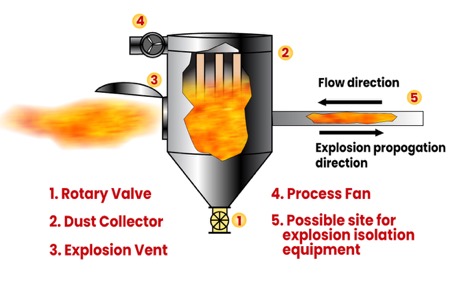

Explosions can propagate to other locations in the plant. However, these risks can be mitigated with explosion isolation technologies, which contain the explosion. This explosion isolation prevents it from spreading throughout the entire process plant. Figure courtesy of CV Technology.

Explosions can propagate to other locations in the plant. However, these risks can be mitigated with explosion isolation technologies, which contain the explosion. This explosion isolation prevents it from spreading throughout the entire process plant. Figure courtesy of CV Technology. The Wood Pellet Association of Canada (WPAC), BC Forest Safety Council (BCFSC) and Dalhousie University have released their final report Analysis of Deflagration Isolation in Wood Pellet Production for Safer Operation.

Process safety and hazard analysis expert Kayleigh Rayner Brown, P.Eng., M.A.Sc., director of Obex Risk Ltd., was commissioned to analyze deflagration isolation for safer operation and conducted the work alongside BCFSC safety advisor Bill Laturnus. Funding for the project was provided by Dalhousie University, arranged by Dr. Paul Amyotte.

With an eye to minimizing the impact of potential combustible dust fires, explosions and deflagrations within wood pellet plants, the project focused on best practices aimed at isolating the potential for this kind of event.

“Deflagration isolation is one of the most important but least understood aspects of an explosion protection system but identifying the isolation points involved is just one step,” said Dr. Chris Cloney, P.Eng., PhD., managing director and lead researcher at DustEx Research Ltd. “The work done will support plant staff’s ability to select, install and maintain the isolation systems over time so they perform when needed.”

Four-step roadmap

The project involved speaking with subject matter experts from wood pellet plants across Canada, engineering consultants and specialists with expertise in combustible dust, as well as experts in deflagration isolation equipment supply. Literature review of relevant National Fire Protection Association (NFPA) standards and resources from the Center for Chemical Process Safety (CCPS) was also completed.

According to Rayner Brown incorporating deflagration isolation follows a four-step roadmap:

- Conduct a Dust Hazard Analysis (DHA) – a systematic approach to identifying and analyzing the fire and explosion hazards posed by combustible dust within a facility

- Work with equipment suppliers on recommended deflagration isolation points

- Install deflagration isolation equipment

- Maintain deflagration isolation equipment

The benefits of deflagration isolation include reduced risk of the effects of a dust explosion, protection of critical process equipment and potential impacts to the environment, and a dramatic reduction in production downtime and possible reputational harm.

“There is potential for a deflagration to occur in many different pieces of equipment, including hammer mills, dust collectors and conveyors, and the risk is it can create a domino effect and cause a secondary explosion, sometimes worse than the first explosion,” said Rayner Brown.

“Deflagration isolation is addressing these risks and helping productivity,” added Rayner Brown pointing to the example of one plant that, after adopting this approach, had an event that, in the past, would have taken it down for two weeks but in this case, it was only down for 24 hours and sustained zero damage.

Next steps

The results of the study have been compiled into a final report, published on WPAC’s webpage www.pellet.org/safety and provide important information on:

- the different types of deflagration isolation systems commonly used in wood pellet facilities and how they work;

- common locations for isolation systems in wood pellet production;

- the installation, operation, and maintenance of isolation systems to improve understanding;

- summaries of the failure modes and degradation factors associated with these systems; and

- considerations for how these failure modes and degradation factors can be managed to make systems more reliable and effective.

Coming up in 2022, WPAC will host a symposium to further delve into the report details, which will include discussions with the experts involved in the study, in an effort to raise safety performance to the highest level.

Print this page