Keeping Warm Up North With Bioenergy

March 29, 2012

By Jack Danylchuk

Mayor Gordon VanTighem delights in the fact that tourists who visit Yellowknife, North America’s diamond capital, are also unintentionally visiting the pellet boiler capital of Canada.

Mayor Gordon VanTighem delights in the fact that tourists who visit Yellowknife, North America’s diamond capital, are also unintentionally visiting the pellet boiler capital of Canada.

|

|

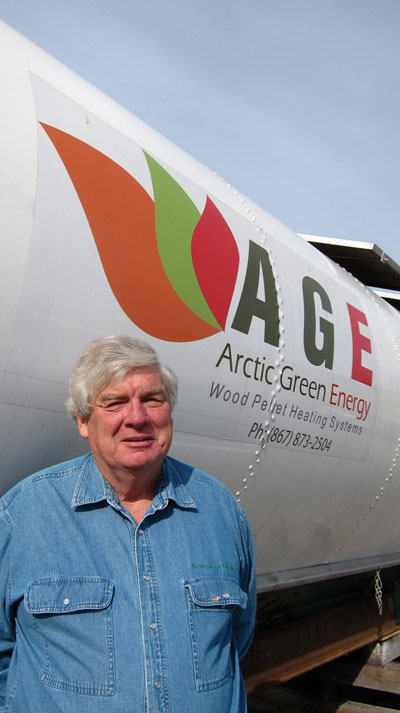

| Bruce Elliott with the pellet boiler Arctic Green Energy uses to heat the North Slave Correctional Facility. The boiler was the first in Yellowknife and opened the eyes of the city and territorial government to the possibilities of biomass fuel.

|

Being 1,000 kilometres north of the nearest oil refinery, Yellowknife lives on the front line of volatile fossil fuel prices. A decade ago, a small factory owner thought wood pellets might be the answer to his dilemma of providing a constant flow of air to his shop without breaking the bank.

Bruce Elliott experimented with wood pellets, concluded there was a business in it, and five years ago sold the territorial government on his vision. “It took a bit of convincing, but once we showed them it worked, their response has been good,” said Elliott.

The first project was the North Slave Correctional Facility in Yellowknife, where Elliott installed the boilers and, under a 10-year contract, sells the heat to the government below the current price of fuel oil.

“It has cost them nothing, and they get green energy.”

Prior to the summer of 2008, oil prices were more than $1.20 per litre, resulting in payback periods as low as three to five years for converting to wood pellets. The government moved quickly to take advantage of the savings, converting many of the buildings in the capital, including the Legislative Assembly. With the current high cost of fuel oil in Yellowknife, biomass-heating projects are reducing the cost of heating 40 to 50%.

According to government estimates, by the end of 2011, Yellowknife’s oil consumption will be reduced by more than two million litres annually. But the potential for savings is even greater, says a report by the Arctic Energy Alliance: “If every public building within Yellowknife was heated by wood pellets, the demand would be 200,000 tonnes per year. A further 1.5 million litres of heating oil could be displaced in government buildings throughout the NWT.”

John Carr, a spokesman for Arctic Energy Alliance, said the regulatory system is still learning and there have been some questions about building code compliance.

“There has been a learning curve, but everyone is getting familiar with it. They see now that it works, that it’s safe and economical.”

The government has invested $60 million in weaning as many of the Northwest Territories’ 45,000 residents off fuel oil as possible, providing incentives to businesses and homeowners to convert to pellet boilers.

|

|

| Gordon Van Tighem is proud to be the mayor of Yellowknife, which possesses the largest number of wood pellet boilers of any community on the continent. |

A recent government study found that pellet fuel consumption in the Northwest Territories is approaching 18,000 tonnes/year – still well short of the estimated 30,000 tonnes needed to support a pellet mill, but Yellowknife’s plan for a district heating system could fill the gap.

The city signed a memorandum of understanding with Corix Utilities last summer for a $60.4-million community energy project that would heat 39 downtown buildings with a mix of wood-pellet boilers and geothermal heat from a defunct gold mine.

The territorial government plans to convert as many of its buildings to pellet heat as is practicable, and Northern Property REIT, the territory’s largest landlord, is taking the same course, boosting demand.

The current need for pellets in the territory is met by mills in La Crete, Alberta, and northern British Columbia, where the forest industry is harvesting trees destroyed by insects.

The NWT Biomass Energy Strategy two years ago released aims to “work with the private sector and Aboriginal development corporations to identify viable business models to produce pellets and/or woodchips in the NWT.”

Producing wood pellets at a competitive price would help stabilize the territory’s supply of pellets, said Jim Sparling, manager of climate change programs with the Northwest Territories department of Environment of Natural Resources.

“If you’re buying in bulk [pellets] from La Crete, you can get them delivered in Yellowknife for about the equivalent of 60 cents/litre for heating oil right now. But there are some concerns about the long-term sustainability of that,” said Sparling.

Environment minister Michael Miltenberger said “as we convert … more government and commercial buildings, and as the price of oil goes up, it will be more and more attractive. We just have to make sure that it’s done in the right way in the right place where we have sustainability of supply.”

Two Fort Simpson businessmen hope to create the first made-in-the-Northwest Territories supply of wood pellets. Wayne McKay and Ivan Simons have a $100,000 grant from the government to build a 1,000-tonne-capacity mill.

Elliott’s company, Arctic Green Energy, brings three B-trains of pellets a week to Yellowknife from La Crete, and he has looked at the economics of manufacturing pellets.

“Thirty per cent of round wood is lost to drying, so it’s not really profitable unless it’s run with a sawmill,” said Elliott. “La Crete is struggling because of its distance from major markets. We’re relatively close to them competing with other southern manufacturers.”

Elliott says he is looking at a cheaper product, but won’t disclose what that is and is also promoting combined heat and power projects for smaller communities that rely on diesel generators.

“We can do that cheaper than oil,” he said. “We’ve done a proposal for the government. The communities can use feedstock they have on hand – fire-burned trees and quick-growing willows to generate sustainable biomass and portable chippers. Boilers will burn chips, not pellets.”

Print this page