Residential Pellets – Quebec District Heat

December 2, 2010

By

Colleen Cross

Direct Pellet Industries Inc. (DPI) expects to begin production in the spring of 2011 in the former Lumber Lane sawmill on Kennaway Road, just outside Haliburton.

Direct Pellet Industries Inc. (DPI) expects to begin production in the spring of 2011 in the former Lumber Lane sawmill on Kennaway Road, just outside Haliburton.

|

|

| Cité Verte’s boiler room, now under construction, is expected to be complete in February 2011. Photo: Cité Verte |

DPI, which also sells Maxim Heat wood pellet stoves, started out retailing pellets obtained from a source in the United States and now operates from depots throughout Ontario. To avoid transport hassles and an unsteady exchange rate on the Canadian dollar, and to ensure a reliable, local supply, co-owners Brad Lyons and Amanda Chort decided about a year ago to manufacture and distribute their own wood pellets. They intend to introduce a European-style distribution system in which the pellet boilers are accompanied by 1.5 to 2-tonne bins that will eventually allow for bulk delivery of pellets. According to co-owner Brad Lyons, “you get the savings of bioenergy with the convenience of propane or oil.”

The two partners plan to hire six plant operators and two truck drivers and sell 40-pound bags of pellets, to be marketed under the Haliburton Highlands brand. The goal is to manufacture between 15,000 and 20,000 tonnes of pellets for the company’s first-year output, running 10 eight-hour shifts each week.

|

|

| Direct Pellet Industries will sell its hardwood pellets wholesale, allowing it to charge a lower price than for other hardwood pellets and about on par with the price for softwood pellets. Photo: Direct Pellet Industries |

Lyons emphasizes that the pellets will be made of clean, pure hardwood from a source in Toronto and will be priced competitively. The mill’s efficient process and central location for delivery to customers in Ontario, Quebec, and parts of the United States make it relatively inexpensive to manufacture and distribute the premium pellets.

Equipment is on site and being installed at the 5,000-square-foot mill. The company is building an 8,000-square-foot fibre building connected to the main building. Lyons has sourced used Andritz Sprout pellet mills, pellet cooler, and fines separator from a closed plant in the United States, along with various conveying equipment. The partners have also purchased a used Carter Day dust collector from the recently closed Kaufman furniture plant in West Virginia.

To design the plant, Lyons and Chort brought on board engineer Tom Smith, former owner of TS Manufacturing near Lindsay, Ontario, who has 35 years in the wood machinery business building sawmills from scratch.

The project has substantial financial support from the Haliburton County Development Corporation, and nearly $850,000 has come from private sources.

Lyons is enthusiastic about the project: “We want to convert people to start burning wood pellets. It’s 70% savings over most other ways of heating.”

Quebec District Heat

After an extensive search, partners in La Cité Verte have purchased equipment and begun construction on the $300-million biomass-based urban district heating demonstration project. The main heating plant is expected to begin operation in time for the 2011 heating season.

|

|

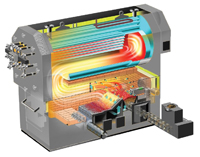

| Four Pyrotec boilers will provide biomass-based heating to Cité Verte’s multi-residence community. Image: Viessmann Group |

Located in central Quebec City, La Cité Verte is an environmentally friendly community intended to manage renewable energy and water consumption while using energy efficient design for building and community energy systems. It is supported by grants of up to $5 million each from Natural Resource Canada’s Clean Energy Fund and Hydro-Québec’s Avenues program.

Claude Routhier, president of engineering at Poly-Énergie Inc., the Quebec City-based energy efficiency specialist of the project, says the project’s district heating system was inspired by a design from Aqotec, an Austrian firm that has recently entered into a partnership with Regulvar Inc., which has offices in Quebec, Ontario, and eastern Canada. The main biomass boiler has been purchased from Waterloo, Ontario-based Viessmann Group, a German-owned company that Poly-Énergie has been involved with since the 1980s.

The 840-unit residence, which has heating demands of 10 MWh, comprises three main elements: boiler, pipes, and substations. The 5-MW boiler plant, which will house four wood pellet Pyrotec KPT1250 boilers of 1,250 kWh each and one emergency natural gas boiler of 5-kWh capacity, is under construction. The boilers are due for delivery in January 2011, with completion expected four to six weeks later. The boiler room will be located in a multi-residential building and boast low-temperature stack emissions. Simon Koeb, business unit manager for Biomass Commercial, Viessmann, describes gasification as a two-stage process: the fuel is first pre-dried and gasified in the burner trough, after which the gas is mixed with a controlled amount of air to achieve its full combustion.

The system will use 2,600 tonnes/year of wood pellets manufactured from bark-free softwood residue by Granules LG International Inc. and delivered in 80 semi-trailer truckloads. Because the heating plant will be located among residential buildings, Routhier says that the developers chose a proven boiler technology that can produce energy as cleanly as possible on a large scale. With concern about emissions and reliability on the minds of the public, “we don’t want to go experimental,” he says.

Making the system as clean and efficient as possible poses challenges, says Koeb. A heat exchanger was added to the back of the boiler, cooling the exhaust to around 30ºC. “I’ve never really seen anybody do that, and that had some implications for our control system, where we had to make some adjustments,” he says.

The project requires a 2-km twin-pipe Logstor circulating water distribution network of twin pipes, the most efficient district heating supply pipes available. Ranging in size from one to eight inches in diameter, they are more efficient than the usual arrangement of two separate pipes, releasing about 30% less energy to the ground as water moves between buildings.

Aqotec is providing 17 aqoCad district heating substations of 30 to 1,400 kW each and offering advice on their configuration. The substations will reduce the amount of piping required on the site and help to reduce overall heat loss.

“We have gone to great lengths to install the most advanced neighbourhood heating system fed by biomass that I can think of in Canada,” says Routhier.

Print this page