Using wood energy for residential heating in rural regions

September 28, 2017

By Allen M. Brackley David Nicholls Maureen Puettmann and Elaine Oneil

Sept. 28, 2017 - Southeast Alaska is a remote island chain, located about 1,100 kilometres north of Seattle, Wash. Most of the region’s goods are imported by barge, creating logistical and economic challenges not faced by many other parts of the U.S. This also applies for many types of wood products. Although the region is heavily forested (including the 17 million acre Tongass National Forest), there are no commercial wood pellet mills capable of supplying the region’s needs.

The Alaska landscape is characterized by remote mountains

The Alaska landscape is characterized by remote mountains Thus, pellets for residential heating must be imported, often from Washington or Oregon. Given the long shipping distances, and the need for fossil fuels to power barges, the net environmental benefits are uncertain, and worthy of further analysis. It is within this context that we used life cycle assessment to evaluate the environmental impacts on global warming potential associated with converting home heating systems from heating oil to wood pellets in southeast Alaska.

Southeast Alaska context

Limited industrial development makes it necessary to import almost all goods into southeast Alaska, primarily by barge. Accounting for carbon associated with heating oil, for example, must include the carbon chemically bound to the product, as well as the carbon resulting from the energy to move the raw product from the north slope of Alaska to Seattle where it is refined and the transportation back to southeast Alaska where it is consumed. Accounting for these energy flows is an important part of comparing alternatives in life cycle analysis.

When planning wood energy applications, it is often desirable to quantify the environmental impacts of harvesting, transporting, and combusting woody biomass compared to alternative fuel sources (typically fossil fuels). Over the past 10 years, close to 10 small industrial scale wood energy systems established in southeast Alaska. Although most of these systems are small (typically burning less than 100 cords of wood or 1,000 tons of chips per year), the cumulative effect is substantial for the rural communities served. This motivation guided our research to perform life cycle assessment on region-wide wood energy use for residential heating under scenarios that compare local fuel production to wood fuel being transported from the continental U.S.

Research objectives

Our research objectives were to evaluate the environmental impacts of residential fuel scenarios in southeast Alaska, including:

- importing wood pellets into southeast Alaska from the Pacific Northwest, versus

- local production of wood pellets in southeast Alaska to supplement current cordwood use.

We compared heating oil, current cordwood use in southeast Alaska (status quo), and the substitution of heating oil versus use of wood pellets. Two scenarios were explored for wood pellet use: imported pellets from Washington state, and local pellet production in southeast Alaska.

Life cycle assessment model development

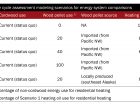

Life cycle assessment quantifies every stage in a product’s life and its interaction with the environment. The outcomes of a life cycle assessment can accurately target the source of environmental impacts throughout a product’s life. In this research we used life cycle assessment to evaluate residential heating scenarios that included heating oil, cordwood, and wood pellets. We considered use of pellets, heating oil, and cordwood energy for residential heating. We followed the methods in the ISO 14000 standards (www.iso.org/) and used Sima Pro software version 8.03 (www.pre-sustainability.com/). Environmental impacts were quantified for global warming potential, smog, eutrophication, and acidification using the North American “Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts” (TRACI). Once the current level (status quo) was established, we evaluated imported pellet utilization at 20, 40 and 100 per cent penetration into the residential heating oil markets. We also modelled wood pellets that were produced and consumed in southeast Alaska, assuming a 20 per cent penetration into the residential heating market.

We considered wood pellet production from both undried and dry mill residues from softwood lumber production in the Pacific Northwest and also from whole tree chips. The base model assumed that pellets were first produced in the Seattle, Washington area then shipped by barge from the Port of Seattle to the Port of Ketchikan, Alaska, then by barge to destination communities within southeast Alaska, and finally by truck for local delivery. Our analysis was based on modelling assumptions for pellets, cordwood, and heating oil, which included specifying moisture content, heating values, and stove efficiencies (Table 1).

Transportation flows for cordwood, heating oil, and imported pellets were determined as well as distances transported both regionally and locally. Our model assumed that locally produced pellets would be shipped by barge to Ketchikan, and then distributed to destination communities similar to imported pellets. Net global warming potential was calculated by subtracting the CO2 absorbed during tree growth from the total CO2 emissions (both fossil and biomass based), using the TRACI version 2.1 method within SimaPro.

Key findings

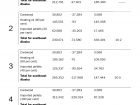

Scenario 1 (the base case), modelled heating oil and cordwood current use (status quo) for home heating in southeast Alaska, but assumed no use of wood pellets. For Scenario 1, net GWP for cordwood was 3,568 tonnes CO2 eq., while for heating oil the net GWP exceeded the total GWP for cordwood at 181,822 tonnes CO2 eq. (Table 2). In Scenario 2, residential cordwood use remained constant, while 20 per cent of household energy from heating oil was substituted with wood pellets. The pellet production for this scenario originated from a hypothetical pellet plant located in the vicinity of Seattle, Washington. The total global warming potential for southeast Alaska under this scenario was 166,491 tonnes CO2 eq, a 10.2 per cent decrease versus the base case (Table 2). In Scenario 3 wood pellets represented 40 per cent substitution of heating oil use for residential heating. Under Scenario 3 the net global warming potential was lowered by 20.5 per cent versus scenario 1 (Table 2). When wood pellets were 40 per cent of the heating oil energy use, total global warming potential for pellets was slightly above that for heating oil (109,163 tonnes CO2 eq. for heating oil and 125,337 tonnes CO2 eq. for pellets). Scenario 4 assumed that 100 per cent of non-cordwood residential energy demands were met by imported wood pellets. This scenario produced a net carbon benefit by reducing net global warming potential in southeast Alaska by 51.0 per cent from Scenario 1 (Table 2). Total primary fossil energy consumption decreased 38 per cent from Scenario 1 while total primary fuels only decreased by 16 per cent. Scenario 5 was the only one to consider local pellet production in southeast Alaska. The primary distinction between Scenarios 5 and 2 is the need in Scenario 2 for pellet transportation by barge from Seattle, Wash., to Ketchikan, Alaska. Here a reduction of 14.0 per cent in GWP was realized by replacing only 20 per cent of the heating oil use with local pellet production (Table 2). Locally produced pellets reduced global warming potential only four per cent versus imported pellets under the same usage level.

Alaska summary and national perspectives

Wood pellet use for residential heating in southeast Alaska was evaluated as a cradle-to-grave life cycle analysis. When comparing the global warming potential of pellets, locally produced cordwood, and heating oil, we found that global warming potential was lower for all scenarios that included wood pellet substitution. These findings support the environmental advantages of increased use of wood fuels in southeast Alaska for residential heating. Environmental benefits can be further enhanced when wood pellets are produced locally to alleviate the transportation burdens due to importing goods to southeast Alaska. These findings are important because locally produced and utilized wood pellets could provide economic benefits to communities in addition to the environmental benefits described earlier. However the limited infrastructure needed to harvest, process and dry wood fibre would first need to be expanded. In the meantime, importing pellets from the lower 48 could be a bridge strategy, after which all forest growth, processing, and bioenergy utilization could occur in southeast Alaska.

Forest resource use is a continually evolving issue in southeast Alaska, and estimating future timber harvest and the availability of material suitable for energy use in southeast Alaska has large uncertainties. The Tongass National Forest transition to young growth is underway, and over the next few decades this resource, and its ability to generate wood energy feedstocks in the form of harvesting residues, small diameter timber, and sawmill residues, will have a major impact on the regions ability to locally produce forest products. Therefore wood energy utilization will continue to be important in creating markets for forest residues from sawtimber.

From a national perspective, many rural communities could benefit from similar strategies in which wood energy products are produced and consumed locally. For example, throughout the western U.S. many sawmills generate significant residues that could be used for fuel. Further, wildfire mitigation thinnings are creating large volumes of in-woods residues that could potentially be used locally. And, in the southeast U.S. large pellet mills are producing large quantities of wood pellets, some of which could be used locally. •

Allen M. Brackley, Ph.D., is currently a research forester located in Sitka, Alaska as part of the USDA, Forest Service, Pacific Northwest Research Station Goods, Services, and Values Team.

David L. Nicholls, Ph.D., is a Forest Products Technologist with the USDA Forest Service, Pacific Northwest Research Station, and is based in Sitka, Alaska.

Elaine Oneil, Ph.D., is the Executive Director of the Consortium for Research on Renewable Industrial Materials, a position she has held since 2009.

Maureen Puettmann, Ph.D., is the owner of WoodLife Environmental Consultants, LLC.

Print this page