The importance of particle size when conducting a dust hazard analysis

June 24, 2020

By Mark Yukich and Ashok Ghose Dastidar

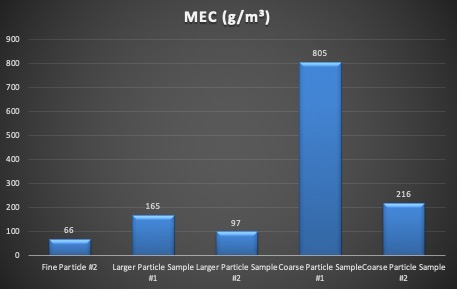

Figure 1: KSt values for various wood dusts.

Figure 1: KSt values for various wood dusts. A Dust Hazard Analysis (DHA) should be completed on any new facilities handling combustible dust (either as an input, output, intermediate or byproduct) before startup, according to NFPA 652. Existing facilities are not grandfathered in and for all facilities that want to adhere to NFPA 652, this retroactive requirement needs to be completed by September 2020. A typical DHA studies a facility’s process from receipt of resources to the storage of final product. Each unit operation along that chain is studied in detail for gaps with, or departures from, the accepted engineering practice which helps reduce the risk of dust explosions and fires. It should be noted that the “dust” from the first unit operation might be different than the “dust” from the last unit operation. This change in dust characteristics can greatly influence the fire/explosion potential or severity – thus affecting the risk analysis and safety review. The characteristics to be considered are chemical composition, particle size distribution, particle shape and moisture content.

In every combustible dust category, particle size plays a role in how the material reacts under different conditions. In this exercise, we will turn our focus on how different wood samples behave in combustible dust testing trials. Unlike flammable liquids and vapors, the particle size plays a role in the final results of testing data. This data, in turn, will greatly influence hazard identification and mitigation strategies. According to NFPA 664 (Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities) Section 3.3.32.1, deflagrable wood dust is defined as:

“Wood particulate that will propagate a deflagration flame front, when suspended in air, or the process-specific oxidizing medium, in sufficient concentration, thus presenting a deflagration hazard.”

The annex of the standard, Section A3.3.32.1, further explains the influence particle size has on wood dust’s explosibility. A key factor to note from this section is: “Flat platelet-shaped particles, flakes, or fibers with lengths that are large compared to their diameter usually do not pass through a 500 μm sieve, yet could still pose a deflagration hazard…Therefore, it can be inferred that any particle that has a major dimension as large as five millimeters (0.2 inches) could behave as a deflagrable wood dust if suspended in air.”

There are some that believe if the majority of dust particles are larger than 500 µm that will protect them or keep them immune from combustible dust hazards. But particles can break down during the handling and cloud generation in process, both intentionally and unintentionally. This is known as the effects of particle attrition. The effect can be important in KSt and MEC tests. The Explosion Severity Test (KSt) demonstrates how strong and how fast a reaction can occur when your sample reacts.

Smaller particle sizes are more reactive

To prove that smaller particle sizes are more reactive, we have conducted some tests and will now share some data points. The first figure (Figure 1) shows KSt data with a variety of particle sizes. Note, the values presented in this article are specific to the samples tested and cannot be used for explosion mitigation strategies of different samples. Dust explosibility values are specific to the sample tested and cannot be used for other wood dusts.

The Fine Particles #1 and #2 had particle sizes of 96 per cent and 79 per cent less than 75 µm when tested. The recommendation by the American Society for Testing and Materials (ASTM) is 95 per cent less than 75 µm when designing explosion protection for your process. This will provide the more conservative value in your data to guard against the particle size attrition that can occur while your material is present within your operation. The protection measures developed using this data and NFPA standards can be considered conservative.

The Larger Particle Size Sample #1 and #2 had particles sizes of 10 per cent and 17 per cent less than 75 µm, respectively. As you can see, the KSt data takes a downturn in the value compared to the smaller particle size.

The Coarse Particle Samples #1 and #2 were tested at 88 per cent and 78 per cent greater than 500 µm, respectively. The chart shows an additional downturn in KSt values. When designing protection protocols for your facility using larger particles sizes, there is a risk that not taking smaller particle sizes into account may pose a risk of an upset in the process.

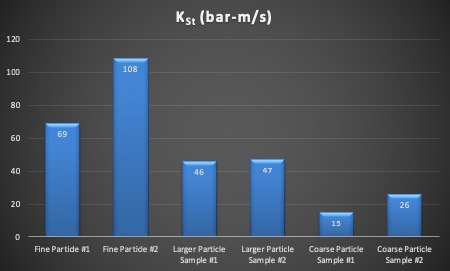

Before we turn our attention to the Minimum Explosible Concentration (MEC) results, we should explain what the values for this test will determine. The data delivered is in grams per cubic meter (g/m³). This test will tell us the density of the dust cloud needed to create a reaction on the sample tested. As a point of reference, if you were standing in a dust cloud of 40 (g/m³) with a 40-watt bulb held at arm’s length in front of you, you would not be able to see that light.

The same samples from our previous example also had testing done for the MEC data. The results are presented in Figure 2 (below).

Once again, the data shows how the smaller particle sizes tend to be more reactive in dust clouds with lower concentration density. As you can see, these concentrations are well above the acceptable hygiene concentrations levels. They are not reached by float wood dust that is in the air at any one time but the settled dust that had accumulated over time. A process accident or upset can then loft these settled wood dusts into the air to create an explosion hazard. This data stresses the importance of good housekeeping as a way to prevent dust explosions and, furthermore, stresses that the greater danger is from fine wood dust. That is not to say that coarse wood dust is not a hazard but that the explosion risk is relatively lower.

The implication for DHAs

In summary, the NFPA proclamation that materials larger than 500 µm are a flashfire or explosion risk is true. A small percentage of fine particles dominate the combustion behaviour of the mixture demonstrated here by the material hazard properties such as KSt, MEC and other data points.

The implication of this for a DHA is that one number cannot be used to solve all problems. The explosibility data used for hazard mitigation and explosion protection for the wood dust at a given facility will be unique to the given unit operation being studied. As part of the mitigation plan, it is prudent to use the worst-case explosion hazard value for protection and prevention design. As an alternative measured approach, the actual material from the process unit operation can be tested, but the values should be used specifically for the process operation considered and not extrapolated to other operations or scenarios.

Mark Yukich is the manager of onsite safety services for Fauske & Associates, LLC. Ashok Ghose Dastidar, Ph.D., MBA, is the vice-president of dust and flammability testing and consulting services for Fauske & Associates, LLC. For more information, visit www.fauske.com.

Print this page