UBC researchers to produce pellets from under-utilized agricultural biomass

June 8, 2020

By Biomass and Bioenergy Research Group, UBC

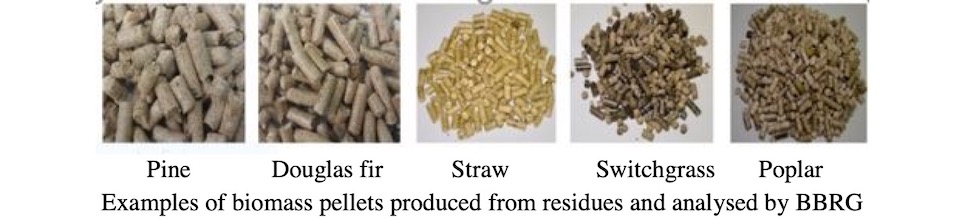

With financial support from Agriculture and Agri-Food Canada’s AgriScience Program, a team of researchers at the University of British Columbia (UBC) aims to produce durable and homogeneous pellets with consistent quality from under-utilized and low-quality biomass resources in Canada. As a member of BioFuelNet Canada (BFN), the UBC Biomass & Bioenergy Research Group (BBRG) is leading this project in collaboration with the Wood Pellet Association of Canada (WPAC) and BFN. This research project is part of BioMass Canada Cluster with the overall goal of mobilizing under-utilized biomass resources in Canada to commoditize biomass for bioenergy, biofuels and bioproducts. Shahab Sokhansanj, Ph.D., the principal investigator (PI), will direct this research project. More information about the project and research team is available here.

The research project, which has received $2.4 million in funding for four years (2019-2023), provides BBRG the opportunity to build on its successful collaborations with the Canadian wood pellet industry in the last decade and to produce and commercialize pellets from under-utilized and low-quality agricultural residues in Canada. The produced pellets will be integrated into the existing wood pellet and grain supply chains to minimize their logistics costs. The final objective of this project is to make these pellets a source of low-carbon intensive and affordable drop-in feedstocks for the production of bioenergy, biofuels and bio-products.

“This is an incredibly exciting project being led by the Biomass and Bioenergy Research group at the University of British Columbia. We are supporting this project because it has the potential not only to grow our bioeconomy with clean energy, but also to add value for farmers’ crops and for by-products that would otherwise be wasted. These are the kinds of clean energy investments Canadians want to see right now,” said Joyce Murray, Minister of Digital Government, on behalf of the Marie-Claude Bibeau, Minister of Agriculture and Agri-Food.

BBRG and its industrial partner, WPAC, have been working together on various initiatives for a decade, focusing on improving the durability, safety and performance of wood pellet production, transportation, storage and handling operations. They have built on their world-renowned track record for leading the research to mitigate the inherent safety and health risks associated with the production and handling of wood pellets, and to improve the durability, quality and logistics of wood pellets produced in Canada. BBRG and WPAC will continue their collaboration to make marketable pellets from agricultural biomass a success, including developing quality certification for domestic, regional and international markets.

With the looming pressure on the sustainable feedstock supply globally and with the implementation of the federal Clean Fuel Standard in Canada, BBRG, BFN and WPAC aim to mobilize the under-utilized biomass resources using pelletization technology to make them available to the national, regional and international markets. Both the sustainability concerns and the greenhouse gas (GHG) reduction potential favour the use of sustainable and low-carbon intensive feedstocks such as lignocellulosic residues. Lignocellulosic residues such as wheat straw are usually left in the field. In some regions, they are collected for local markets such as animal bedding. Canadian farmers in a few places still practice straw burning as a means of controlling insects and weeds, reducing the excessive residue load and returning nutrients to the soil.

Despite the abundance of lignocellulosic residues in Canada, they do not currently contribute to the production of biofuel in Canada and their use for bioenergy is very limited. A primary barrier is low and inconsistent quality and inefficient logistics of lignocellulosic residues, a pain point that was deeply felt by the cellulosic ethanol pioneers in the United States, which resulted in the slow down or shut down of these facilities. One of the lessons learned from these projects is that using straw bales directly as a feedstock in commercial biofuel projects is very challenging and inefficient. Turning bulky biomass with diverse properties to a uniform format, predictable properties and logistically advantageous pellets present a solution.

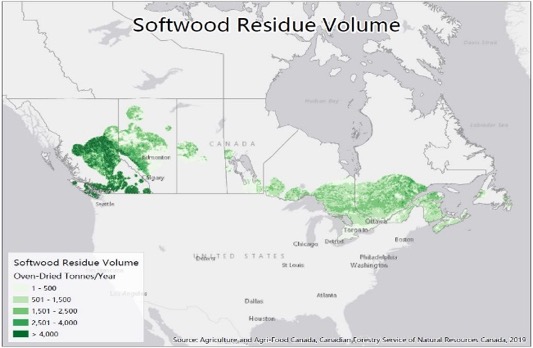

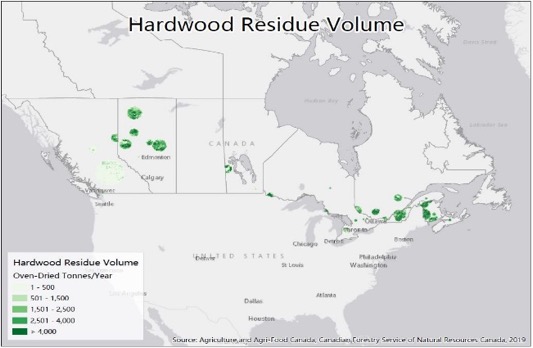

Availability of agricultural and forest biomass in Canada (BIMAT, Agriculture and Agri-Food Canada, 2019). About 50 and 37 million dry tonnes of forest biomass (e.g. low-grade logs, logging residues, urban wood waste) and agricultural residues (e.g. wheat, barley, corn, oat and flax) are produced annually in Canada.

Print this page