Wood and wood products: loss history from the 2019 Combustible Dust Incident Report

June 24, 2020

By Chris Cloney

Graphics courtesy DustEx Research Ltd.

Graphics courtesy DustEx Research Ltd. Fires and explosions pose a significant hazard in industries generating or processing combustible dust at their facilities.

But how many are actually happening… and how severe can they actually be?

This is the question that we at DustEx Research Ltd. set out to answer when we started the Combustible Dust Incident Database in 2016 at DustSafetyScience.com. This is the reason we have been releasing global incident reports and analysis every six months since then.

[This article is part of Dust Safety Week 2020. Find more articles here.]

What has been recorded to date?

Since launching the combustible dust incident database, we have recorded 632 fires, 243 explosions, 417 injuries and 45 fatalities from dozens of countries around the world.

Over those four years, the United States has averaged 112.5 fires, 33.2 explosions, 39 injuries and three fatalities per year, and Canada has averaged 13.5 fires, 2.7 explosions and 3.5 injuries. The incidents captured each year are given in the t able below.

Table 1: Summary of Combustible Dust Incidents Recorded from 2016 to 2019. Modified from the 2019 Combustible Dust Incident Report1 at DustSafetyScience.com.

In 2019, 87 per cent of the fatalities and 73 per cent of the reported injuries occurred from dust explosions. In contrast, 80 per cent or more of the incidents with reported damages in excess of $1,000,000 occurred from fires. These results indicate that both dust fires and explosions are important to control to reduce personal, financial and facility loss from combustible dust incidents.

It is important to note that only a small fraction of the total combustible dust incidents is being captured in the incident database. This is true in North America and even more so internationally, which will impact the analysis provided in the incident reporting.

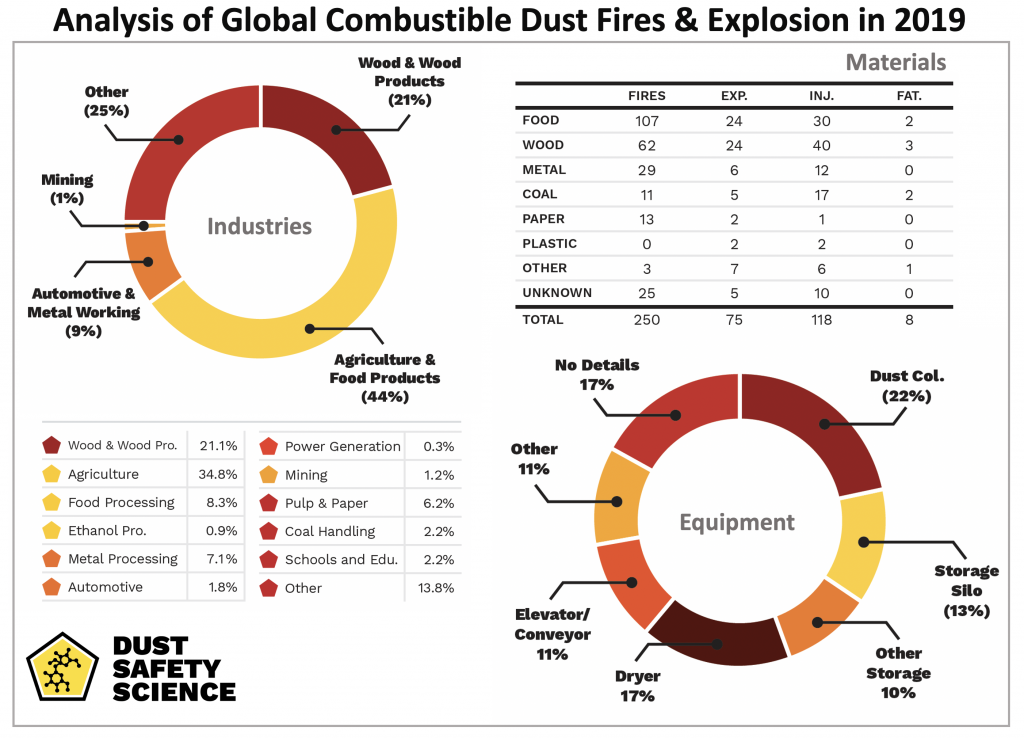

What materials and equipment are involved?

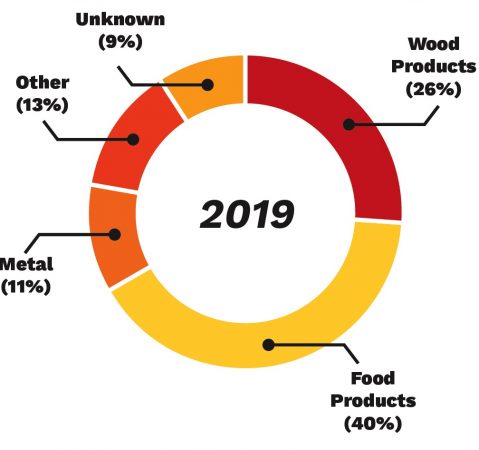

In 2019, 62 of the combustible dust fires and 24 of the explosions reported involved dust from wood or wood products. These incidents resulted in 34 per cent (40) of the injuries and 37 per cent (three) of the fatalities reported in 2019.

The pie chart below gives a breakdown between the different materials analyzed in the incident report. The “Other” category includes coal, paper, plastic, textile and other materials less frequently mentioned.

Figure 1: Summary of materials involved in combustible dust fires and explosions from the 2019 incident report.

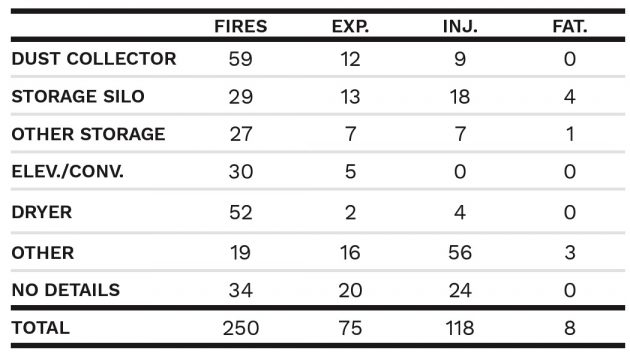

Dust collectors are the most often-referenced piece of equipment involved in combustible dust fires and explosions.

This was also the case in 2019 where 21.8 per cent of the incidents involved this equipment. However, this is lower than the historical data from the U.S. Chemical Safety Board’s Dust Hazard Hazard Study2 report, which suggests up to 40 per cent of combustible dust explosions involved dust collectors.

Table 2: Breakdown of fires, explosions, injuries and fatalities recorded by equipment in the 2019 incident report.

Although more incidents occur in dust collectors, they may tend to be less severe than other equipment. Dust collection systems resulted in 7.6 per cent of the injuries and none of the fatalities in 2019. Storage silos, bins, hoppers and other pieces of storage and transportation equipment tend to result in more injuries and fatalities where most resulted from dust explosions.

Examples from wood and wood product industries

There is very little data outlining the initiating cause of dust fire and explosion incidents from the incident reporting.

However, some interesting trends that relate specifically to wood and wood products have been seen.

For instance, in 2018, all “high loss” incidents (in terms of costing more than $1,000,000 in damages) that occurred in North American wood handling industries mentioned accumulation of sawdust, wood chips, lumber or insulation as contributing to the rapid spread of building fire and increased difficulty for firefighters to respond to the incident. This availability of fuel to feed the fire in these industries is a leading factor in large damages to the facilities. The difficulty in firefighter response also contributes to increasing the overall loss.

In 2019, three dust explosions were reported in North America that caused injuries to workers or fires responders:

- A contract worker was injured from a flash fire that occurred when he was working on ducting at an oriented strand board plant. It is unclear if hot work was being completed at the time.

- Contractors welding a hopper containing sawdust caused an explosion at an industrial facility. A firefighter received hospital treatment for heat-related issues during the response.

- Local media reported residents hearing an explosion at a particle board plant. Later, the company indicated that the deflagration was safely vented, preventing an explosion but that a fire ensued. Four employees were hospitalized for smoke inhalation and treatment.

Also in 2019, fires were reported in a dust collector at a woodworking shop, at a wood pellet plant, and at a sawmill due to sawdust igniting on an exhaust manifold in North America. These incidents resulted in injuries to four employees and one firefighter.

Internationally, more tragic disasters were reported in woodworking industries including fatal dust explosions in Belgium and Spain, and a fatal fire involving a sawdust dump station at a plywood factory in Myanmar in 2019.

Closing thoughts

It is well-established that fires and explosions can and do lead to loss in industries that handle or generate combustible dust. The part that is less clear is how often these incidents are happening and what the overall impact is on workers, facilities and product.

These are some of the questions we continue to tackle with our combustible dust incident reporting and analysis. Results from 2016-2019 indicate that dust collection systems may have the largest number of fires and explosions reported. However, explosions in silos, bins, hoppers and other storage equipment may end up being more deadly.

Sawdust accumulation throughout the facility and housekeeping deficiencies increase the severity of these incidents and may result in larger damages through fire spread and difficulties in firefighter response.

Incidents causing injuries, fatalities and large facility damages involved missing core concepts of an effective dust safety strategy including contractor work programs, hot work programs, explosion prevention and protection equipment, response to dust fires and reducing accumulation of sawdust and dusty materials throughout the facility.

If you want to learn more about Dust Safety Science or the incident reporting, we encourage you to visit DustSafetyScience.com. A pdf of the incident report can be downloaded here and a summary is provided in this article for the interested reader.

References:

- Cloney, Chris (2020), “2019 Combusitble Dust Incident Report – Version #1”, DustEx Research Ltd. Retrieved from www.dustsafetyscience.com/2019-report

- US Chemical Safety Board (2006), “Combustible Dust Hazard Study” Report No. 2006-H-1

Chris Cloney, Ph.D., (PEng.) is managing director and lead researcher at DustEx Research, a company with a world-wide focus on increasing awareness of combustible dust hazards and reducing personal and financial loss from fire and explosion incidents. Find out more about his research work at DustSafetyScience.com or their education and training platform at the Dust Safety Academy.

Print this page