Brunette launches four new products

June 29, 2010

By Brunette Industries

|

June 29,

2010, New Westminster, BC – Brunette Industries Ltd. has launched four new

biomass-related products this year.

Brunette Reclaimer

|

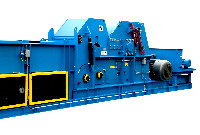

The Brunette

Reclaimer is a bin-type debarker, developed to increase your fibre supply by

performing quality debarking of difficult material such as log yard debris,

pulpwood of various diameters, cedar, and frozen aspen. It features a rugged,

simple design that efficiently separates valuable wood fibre from dirt and rock

as it debarks. The robust design minimizes the need for large spare parts

inventory and makes the Reclaimer easy and inexpensive to maintain. It is

available with hydraulic or electric drive, and works as a batch feed with side

discharge (as shown) or continuous feed with end discharge gate.

Brunette BioSizer

|

Brunette’s

trademarked BioSizer is a rugged, high-speed, waste wood grinder specifically

designed to produce a fine, consistent product. It’s built to be low

maintenance with a high inertia rotor and fixed hammers. Four rows of staggered

hammers provide maximum bites per revolution. This grinder processes oversized

“bush-grind” hog fuel, trim blocks, wood chips, demolition materials, and

typical urban wood waste to a fine, consistent size for the biomass industry.

The main frame is protected with internal bolt-on replaceable wear liners. The

grate has a progressive rectangular hole pattern and can be easily changed out

to other hole patterns to suit the required product size.

Brunette Smartvibe Vibrating Conveyor

|

The

Brunette Smartvibe Vibrating Conveyor is a novel and simple vibrating conveyor.

Its design optimizes low-cost maintenance and maximum uptime efficiencies with

a springless vibratory mechanism that is fully balanced at each stroke. The

patented design allows operators to increase conveying speed through the

use of controls without costly shutdowns. Speed is varied using a variable-speed

drive to control the drive motor RPM that effects the conveyor stroke. This

conveyor is suitable for many industries, including biomass, recycling, pellet

manufacturing, sawmill, plywood, OSB, food processing, and agricultural

industries. It’s available in various widths and lengths, complete with

size-specific screening options and metal detection, and can be

custom built to suit the customer’s needs.

Key

features:

- Fully

balanced - No coil

springs - No

external balance beams - Adjustable

stroke / variable speed - Rocker

arm assembly - Torsional

shafts - Polyurethane

bushings - Eccentric

drive shaft - Rubber

Elastomer springs - Standard

bearings

Brunette Whole Log Chippers

|

Brunette

has expanded its chipper line-up to include a whole-log chipper. This

horizontal feed chipper has a powered upper press roll and powered lower

bedroll to control the feed of the logs to give a high-quality chip. Two rotors

are available: a standard rotor for up to 1¼-inch nominal pulp chip, and the new

MicroChip rotor, which is designed to produce a ¼-inch nominal chip. Each rotor

can be outfitted with the standard Brunette quick-change knife system or the

“disposable” key knife system.

A hard

surfaced anvil mounted in a breakaway support frame prevents damage from

foreign material. The knife to anvil clearance is easily checked through access

doors mounted on each side of the chipper frame. The rear access platform and

hood make knife maintenance easy and safe. The whole-log chipper includes a common

sub-frame that ties the in-feed, chipper, motor, and HPU together for rigidity,

and one-lift installation. It’s available in various sizes and model

configurations.

Print this page