Conveying & Storage Gear

June 15, 2010

By CanadianBIOMASS

To complement our material handling feature in this issue of Canadian Biomass, we have compiled a listing of new products, product upgrades, feature products, and systems and service providers for biomass conveying and storage. All information has been provided by the suppliers and manufacturers.

To complement our material handling feature in this issue of Canadian Biomass, we have compiled a listing of new products, product upgrades, feature products, and systems and service providers for biomass conveying and storage. All information has been provided by the suppliers and manufacturers.

|

|

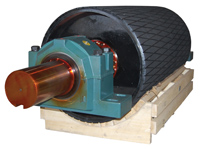

SUPERIOR INDUSTRIES

Superior Industries, which manufactures conveyor systems and components, has a new Core Systems design program. Core Systems offers drive and tail pulley assemblies custom-engineered for specific applications. It creates cost efficiencies for customers by ensuring that drive components are ideally suited for the particular job specifications while making sure that power requirements are met. Each custom-engineered drive assembly is delivered as a pre-assembled package, eliminating the costly labour involved in on-site assembly and reducing installation time. The shaft on each assembly is protected by a specially developed rust prevention treatment.

www.superior-ind.com , 1-800-321-1558

|

|

KEITH WALKING FLOORS

Walking Floor systems from Keith Manufacturing are integrated into material handling systems as receiving, storage, and metering bins. The Keith DrivOn bin is designed to facilitate the delivery of material directly into the plant distribution system. Material is unloaded directly onto the DrivOn bin, where it is stored and metered as needed. The Walking Floor system handles difficult materials, providing the ability to move solid materials of almost any size. The load is distributed across reciprocating slats, resulting in a conveyor with low power requirements. Systems are designed for commercial, agricultural, and industrial customers and used in many applications.

www.keithwalkingfloor.com

WESTERN PNEUMATICS

Western Pneumatics manufactures equipment and systems to handle all types of wood byproducts. Belt, chain, or screw conveyors can move and meter large or small mass flow rates of material. Dust control plays an important role when moving wood; with the new POP filter, Western Pneumatics can clean various air volumes with the most efficient patented cleaning system. High-pressure systems can move large quantities of wood efficiently to various places at a plant site. If wood needs to be transported off-site, Western Pneumatics’ truck bins are the heaviest built and can store 15 to 42 units per bin.

www.westernp.com , 1-541-461-2600

|

|

EDEM/OPTIMIL CONVEYORS

All Edem medium, heavy, and extra-heavy duty vibrating conveyors for wood waste, chips, hog fuel, and oriented strand board/panel board operations are available in both unbalanced and dynamically balanced configurations. Every Edem vibrating conveyor has a rugged coil spring/eccentric shaft drive assembly. This simple, reliable design feature means that Edem conveyors have very low horsepower requirements. Power is provided by a premium-efficiency, totally enclosed fan-cooled electric motor and standard/V-belt drive. Each conveyor is custom engineered to exact customer requirements. Options include double action screens and perforated plate sections, plus units with Edem metal detector and patented magnetic traps that remove tramp metal.

www.edem.com , info@optimil.com, 604-946-6911

|

|

LAIDIG SYSTEMS

Laidig Systems offers a solution to silo/bin hang-up problems: higher delivery rates using the rugged and improved Model 698 Silo and Reclaimer System. This track-driven reclaimer has a sweep auger rotating 360° around the bin, helping create mass flow and enhancing first-in-first-out flow. The Model 698 Reclaimer handles a variety of biomass materials including wood chips, sawdust, shavings, corncobs, and other cellulosic materials for both process and fuel. In addition to the complete line of track-driven silo reclaimer models, Laidig offers an entire family of heavy-duty flat bottom and cone bottom reclaimers, which can be installed into new or existing silos, bins, and domes.

www.laidig.com , 1-574-256-0204, sales@laidig.com

|

|

BRUNETTE INDUSTRIES

Brunette Industries is launching a novel and simple vibrating conveyor. Its design optimizes low-cost maintenance and maximum uptime efficiencies by being fully balanced at all strokes and using a springless vibratory mechanism. The stroke is changed by adjusting the rpm of the drive motor via a VFD input. This versatile conveyor is suitable for many industries, including biomass, recycling, pellet manufacturing, sawmilling, plywood manufacturing, oriented strand board manufacturing, food processing, and agricultural industries. It is available in different widths and lengths, complete with size-specific screening options and metal detection. The Brunette Vibrating Conveyor is built to suit the customer’s needs.

www.brunetteindustries.com

|

|

HALLCO LIVE FLOORS

Hallco Live Floor systems are used for the self-loading and unloading of all forms of woody biomass, demolition debris, tree trimmings, mill residues, and green wastes. Hallco Industries can supply any number of its drive units and deck styles to fit any trailer specifications.

www.hallcoind.com , info@hallcoind.com

|

|

CLARKE’S FLO-MATIC STORAGE BINS

The Clarke’s Industries’ Flo-Matic storage bin provides for an economical means of storage and metering of waste wood products. Material enters through the top of the bin and is distributed full length via a mechanical conveyor. The Flo-Matic bin has reinforced negative sloped steel wall panels that are smooth on the inside. The discharge system from the bin uses a heavy-duty auger that is forced into the material pile by a traverse mechanism drive. As the auger turns, it discharges a controlled flow of material out one side of the bin onto an accumulation conveyor, which transports the material outside of the bin.

www.clarkes-ind.com , 1-541-343-3395

|

|

BRUKS CONVEYOR REDESIGNED

Bruks has redesigned the head pulley unit on the popular Tubulator air-supported belt conveyor to include provisions for a snub pulley, an integrated gravity take-up pulley, and an extended discharge chute with a scraper conveyor to control fugitive dust and debris inside the enclosure. In combination with industry-standard belt scrapers, the Bruks Tubulator head pulley remains clean. This new unit has been incorporated into several installations. A cushion of air supports the belt down the length of the conveyor, which has no idlers. Small fans provide air pressure to suspend the belt inside a tube.

www.bruks.com , Desmond Smith: 1-360-348-2220 or des@bruks.com

|

|

DOPPSTADT DUS CONVEYORS/

SORTERS

Doppstadt DUS waste wood/fibre conveyors and sorters are available with electric or diesel hydraulic drives and have integrated SM start/stop controls. Units have 64-inch discharge chutes with open troughing at chute areas. Options include hydraulic head and tail fold, cross-belt magnet, auxiliary hydraulic connections, stabilization crossbars, and transportable models.

www.groundworx.ca , 780-463-7077

|

|

PROCESS BARRON RECLAIMERS

ProcessBarron has been manufacturing and installing rugged, reliable biomass reclaimers throughout North America for over 20 years. From underpile drag chain reclaimers, circular screw reclaimers, and travelling screw reclaimers to fixed or radial stack-out conveyors, ProcessBarron does it all. Reclaimers vary in fuel storage capability, but ProcessBarron will custom design a system to match power production needs and budget constraints. Reclaimers are coated with special abrasion materials to protect them from erosion, with shafts, bearings, and drive components engineered to handle the forces and stress of biomass. Motion sensors and plugged chute monitors also are available to provide reliable operation.

www.processbarron.com

|

|

ALLIED BLOWER

Allied Blower & Sheet Metal Ltd. is a turnkey systems expert with over 35 years of design, fabrication, installation, and service expertise in conveying, handling, and storage equipment. Allied worked on the first North American high-moisture waste-wood energy system, as well as numerous pellet mills and wood energy projects across Canada, including the current Kruger tissue/Nexterra syngas power plant in New Westminster, BC. Customers include Pope & Talbot, Luscar, Pacific BioEnergy, Pinnacle Pellet, Peace River Coal, Epcor, Grande Cache Coal, Canfor, and Weyerhaeuser. Allied completes more than 3,000 projects annually, creating systems for dust control, wood, and pneumatic conveying, and fabricating components and systems for gas cleaning and volatile organic compounds control.

www.alliedblower.com , Bruce Wendel: 604-930-7000

|

|

MACHINAGE PICHÉ

Founded in 1983, Piché designs and manufactures wood handling and processing equipment. The company is Canadian Welding Bureau-certified and also works in the industrial manufacturing sector as a subcontractor. It is managed by a young, dynamic team boasting several years of experience. This team is backed by qualified professionals in engineering, estimating, accounting, administration, project management, manufacturing, and installation. The manufacturing facilities, equipped with state-of-the-art technology and qualified employees, enable Piché to design a wide variety of high-quality industrial equipment at low cost. The machining department has the tools required to produce both precision and larger parts.

www.picheinc.com

Print this page