Industry set to Explode

May 27, 2009

By

Heather Hager

As the costs of fossil fuels escalate and climate change policies come

into force, the use of woody biomass for energy is becoming an

increasingly attractive option.

As the costs of fossil fuels escalate and climate change policies come into force, the use of woody biomass for energy is becoming an increasingly attractive option. This was the topic at the pre-DEMO bioenergy conference held in Halifax, NS, in September by the Canadian Woodlands Forum and CanBio. The focus was largely on the Maritimes, and over 200 individuals from both national and international industry, government, and academia discussed the current status of the biomass industry both in Canada and abroad, including what biomass is available and what can be harvested, as well as techniques to obtain and transport biomass efficiently, and opportunities for emerging biomass markets. Ultimately, there seems to be a lot of potential for Canada to create its own unique identity in the biomass industry.

|

|

| In Canada, it would require an engineer on site 24/7, much like Taylor Lumber’s similar size plant in Nova Scotia, creating a major hurdle to small-scale projects.

|

Biomass availability

Biomass in Canada is currently produced mainly as a byproduct of the lumber industry or from the harvest of nonmerchantable timber. However, slumping lumber markets and sawmill closures have reduced the supply of sawmill residuals available. Thus, it may be necessary at times for the forest industry and policy makers to consider the harvest of forests for energy as a final product in itself.

It is difficult to estimate the current use of biomass for energy purposes because actual numbers are not always available, for example, the consumption of firewood by small woodlot owners or the internal use of sawdust and hog fuel by sawmills. However, David Palmer, general manager of the York-Sunbury-Charlotte Forest Products Marketing Board, estimates that the use of biomass to generate heat, steam, and electricity replaces at least 5.1 million barrels of oil annually in the Maritimes, and increases in the demand for firewood and the future planned construction of sawmill boilers and pellet mills will account for the replacement of another 1.3 million barrels. This may just be the tip of the iceberg.

The increasing and potential markets for woody biomass in lieu of fossil fuels seem a boon for the forest industry, but there are also a number of concerns within the industry. The chief concern is the lack of policies and guidelines regarding what can be harvested, from where, and how much. “We’ve only scratched the surface of what’s out there,” says forester Doug Prebble, and this seems to be the general consensus. The question is, what is sensible and practical to take, from both a commercial and an ecological viewpoint?

Sustainable biomass harvests

Trees are a renewable resource, so it makes good sense to ensure that forest ecosystems will continue to be viable. Biomass harvesting involves the additional removal of logging residues, or slash. “In biomass harvesting, we are taking more parts from the forest, so what is the effect of that?” asks Michael Main, research associate at Nova Scotia Agricultural College. In terms of nutrients, the whole tree can contain two to three times the amount of nutrients contained in the main stem alone because the foliage has a high proportion of the total nitrogen, calcium, and other nutrients.

Cations such as calcium, magnesium, and potassium are important in the soil because they act as buffers to limit the solubility of iron and aluminium. Unchecked, these latter elements will increase soil acidity and can be toxic to plants at high concentrations. This soil buffering capacity differs with soil depth such that shallower soils are at greater risk of adverse harvesting effects.

Past studies that have examined nutrient flows indicate that the effects of biomass harvest on soils depend on various factors such as the underlying geology and soil thickness of the site, forest practices, acid and nitrogen deposition from the atmosphere, and the tree species. However, much more than just soil nutrients is affected by harvesting, stresses Dr. Evelyne Thiffault, researcher with the Ministry of Natural Resources.

It is imperative to consider other effects of the biomass harvest than simply that on soils when deciding what makes a sustainable harvest. Is the goal to sustain tree productivity, biodiversity, water quality, social values of forests, or perhaps all of these? Even looking to countries that have more experience in this matter such as Sweden, Finland, and the UK can only provide clues as to what makes a good indicator of site suitability for biomass harvest. The use of different indicators (soil depth, soil acidity) can produce completely different results.

|

|

| This small co-gen plant in Sweden runs automatically at night and during weekends, using automated computer controls and alarm pagers.

|

This conundrum has created confusion for forest managers, who want to know what they are to do in the meantime to maintain sustainable forest harvests until scientific knowledge can provide more robust answers. However, both Main and Thiffault stress that biomass extraction can proceed if it is managed intelligently. First, they recommend the avoidance of whole-tree harvests in sensitive sites; for the Maritimes, such sites might be those with shallow, coarse-grained soils. Second, it is generally a good idea to leave foliage and twigs behind after harvest. Thiffault recommends the use of common sense biomass extraction guidelines such as those used in Finland, where 30% of residues are left at the site. In most cases, it would be economically inefficient to collect this material anyway.

Third, Thiffault stresses the importance of monitoring real operations to obtain greatly needed information. Fourth, managers and policy makers should use adaptive management to evaluate and alter guidelines on a site-by-site basis depending on local knowledge and the availability and acquisition of appropriate data.

Biomass market opportunities

Of course, the harvest of biomass in the absence of market opportunities would not be economically sustainable. Biomass should compete for a piece of the energy pie that is currently occupied by fossil fuels, explains Jim Verboom, president of Verboom Grinders, a Truro-based biomass supplier and one of the largest in eastern Canada. The forest industry should look to expand current markets, including firewood, chips, hog fuel, and wood pellets for heating, as well as to develop potential future markets for biomass and biomass products, including wood/coal co-firing to produce power, the co-generation of heat and power, and processes to further refine biomass such as gasification, pyrolysis, and torrefaction, and even carbon credits! Because Canadian biomass markets are in their infancy compared to those of Europe, particularly Scandinavia, there are many opportunities to get in on their development, including the development of industry policies.

Take the wood pellets industry, for example. According to John Swaan, executive director of the Wood Pellet Association of Canada, Canada produced approximately 1.5 million tons of wood pellets in 2007. Only 14% of these were sold in Canada, with 32 and 54% going to the U.S. and overseas, respectively. The European Union nations in turn benefit from carbon credits that they receive from the use of pellets. Considering the increasing cost of ocean shipping and Canada’s commitment to the Kyoto Protocol, it would be advantageous to create and increase domestic uses for these pellets.

In other markets, the technology for energy and power generation that is currently commercially available for biomass is based on oxidative combustion. The greatest opportunity here seems to be in biomass co-firing, in which biomass is treated in some manner such as grinding and then used to replace some of the coal used in coal-fired power plants. This requires only slight modification of existing plants to install biomass storage and feed systems. According to Fernando Preto of Natural Resources Canada, Ontario Power Generation has been conducting short co-firing tests using various types of biomass since March of 2006 at the Nanticoke plant, so these results are something to look for in the future. Canada should look to places like Finland, where co-firing is common, as a springboard to develop its own co-firing policies (Editor’s note: These tests have been successful, so OPG is expanding this project dramatically – see page 21).

Up-and-coming technologies include gasification and thermochemical conversion, or pyrolysis. Gasification ultimately results in the production of synthetic gas, which can be used as a fuel or further processed to make other products. Several North American companies have woody biomass gasification plants at the pilot and demonstration stages. The pyrolysis of biomass produces a corrosive and easily polymerized substance, requiring some modification of burners before the pyrolysis oil can be burned. Four companies in Canada currently produce pyrolysis oil, according to Preto.

One of the major barriers to the expansion of the biomass industry in Canada was noted by Bruce McCallum of the Canadian Bioenergy Association (CanBio) as the lack of bioenergy policy frameworks and inconsistencies in policies and programmes at all levels of government. Archaic requirements for 24/7 boiler engineers for the smallest co-gen plant is an example. There needs to be a push within and among governments to develop long-standing policies and programs for bioenergy that specifically address biomass as a form of energy. In addition, to facilitate markets and technology exchange, standards need to be set or Canadian standards made compatible with European and U.S. standards when possible.

Another barrier to address is that of consumer confidence in product availability and maintenance. There is a need for the coordinated introduction of technology and resources, for example, pellet-burning residential furnaces and pellet supply. Policies should introduce incentives for people or organizations that want to convert from fossil fuel to biomass consumption. Addressing these barriers can only be advantageous: budgets will be reduced by switching public institutions to biomass heating, co-generation can reduce power and heating costs, Canadians will gain access to biomass forms of heating, price and supply should become more reliable and stable, and jobs will be created.

Efficient biomasstransfer

Given that biomass is available, can be harvested sustainably, and there are market opportunities, the final major object of consideration is the efficient and economical transfer of biomass from the forest to the processing plant, and ultimately, its final destination. According to Mark Ryans of FPInnovations’ Feric division, as well as several experienced producers, comminution and transportation are the most costly parts of the transfer chain. This makes sense because of the capital costs and fuel costs involved in operating the machinery.

|

|

| Verboom Grinders’ newest horizontal grinder, a Peterson 5710. With hourly costs in the $300 range, keeping such machines working is a key to biomass harvesting success.

|

Several recommendations were made regarding comminution and transportation. The main harvest and the recovery of biomass, e.g., pre-piling, should be integrated to reduce both costs and contamination of the biomass, the latter of which can increase machinery maintenance costs. Efforts should be made to minimize the amount of time that grinders and trucks are idle. Biomass should be treated in a manner that minimizes the moisture content so that weight costs are for energy, rather than water content. Finally, efforts should be made to improve domestic markets, ultimately reducing shipping costs.

There are multiple ways to address each of these factors; the producer should take care to consider the whole production chain to determine which methods are most suitable for his or her particular operation and invest in equipment that will serve multiple purposes.

The final message to be taken from the bioenergy conference is that there is much to be done in the Canadian biomass industry. There are lots of opportunities to step in and become part of its development, from production, technology, and research to policy development. And there are lots of potential benefits to be had by becoming involved.

Taylor-Made Solutions

Nova Scotia sawmill got into the co-gen game before the current energy price explosion and quest for renewable energy made it popular.

Taylor Lumber of Middle Musquodoboit, NS, has been dubbed a “Biomass Pioneer” by provincial utility Nova Scotia Power for good reason. The privately held sawmill, planing operation, chipping plant, and reman facility just outside Halifax added its 1.15 MW co-gen facility back in 1995. That’s long before $140 barrels of oil, and a full 13 years ahead of NS Power’s recent Request for Proposals (RFP) for 25 MW of additional biomass power.

|

|

| Patrick Paiement of Quebec biomass player Gestion Cyclofor grabs a handful of hog fuel in the Taylor yard. Fuel includes everything from large hog fuel as moist as 65% MC to sawdust and planer shavings down to 10% MC or less.

|

While the move was only partly because of energy costs at the time, the end result has been the same – the co-gen plant is no doubt a key ingredient in Taylor’s ability to keep its 100 or so employees working through some of the toughest times the industry has faced. It also helped the mill meet a few other challenges at the time it was installed.

“We ran into a problem with our biomass here about 18 years ago,” explains company president Robert Taylor when asked during the CanBio/CWF conference field tour for the reasons behind the timely investment. “We were putting biomass into landfill and things like that. We saw the writing on the wall that it was going to be an environmental issue, and we knew there had to be better ways to use the material. We could also see our power consumption growing because of some expansions we had planned. It’s always hard to see the future in this business, but we based our power consumption estimates on our plans at the time, and it looked like we’d need more power. Altogether, the investment in co-gen looked like a good one.”

Also, like many other Maritime sawmillers at the time, Taylor was adding kiln drying capacity in the 1990s, so heat, steam, and power would all be welcome.

Flexible Burning

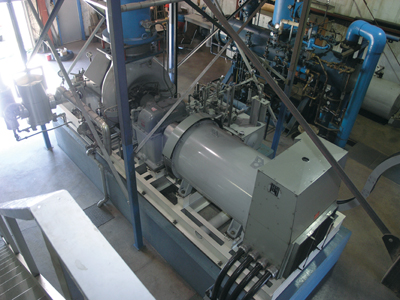

The result was a combination turnkey project for the boiler from KMW Energy Systems of London, ON, with what Taylor calls a “piecemeal project” for the rest. The boiler was chosen for its ability to handle a wide range of feed stocks, the majority of which are produced on site by the mill.

|

|

| The ability to take fuel of various sizes and quality was a major reason for choosing the KMW boiler.

|

Hog (bark) constitutes 40% of the supply and is stored at the edge of the mill yard. Judging from the piles on site during our visit, both the size and quality of the hog fuel varies widely. Sawdust (40%) and shavings (20%) are stored inside, transported to the appropriate sections of the warehouse by a simple, but effective, overhead conveyor with diverter gates. Shavings are stored separately and are bagged for the animal bedding market as required. In fact, an upcoming project is a more efficient bagging system for this hot market.

Feedstock is blended and brought to the KMW boiler via a drag chain conveyor. Here, moisture can be added if the blend is too dry, as was the case when Canadian Biomass was on site. Despite its small scale, the plant is manned 24/7 by a stationary engineer to meet provincial regulations (one of many that parties like CanBio are trying to get changed).

The wood residues are burnt and resulting gases re-burnt for maximum efficiency and minimal emissions. The entire process is controlled from an operator’s booth perched between boiler and turbine.

The mill generates 100% of its own power needs and sells power to the grid daily. Future plans for the shavings baling line, a pallet operation, and even aquaculture among others will reduce power available for sale, yet thanks to this 13-year-old investment, the power is there for the taking. This is far from always the case for rural sawmills in this part of the world.

“I think the industry has to look at a variety of energy sources down the road,” Taylor predicted a few years back in a NS Power video promoting bioenergy. “For us it’s something that worked out really well, and it will be a big part of our operation in the future.”

When asked why the 15 million bdft operation has managed to avoid the heavy downtime plaguing most of the industry, Taylor remained cagey. Luck is a big factor he said with a smile. Looking around the yard at the wide range of specialty products, niche marketing no doubt plays a role as well. Still before we climbed back on the tour bus, he admitted that the co-gen plant has been a factor.

“It’s been an aid, for sure. It’s just part of the equation now.”

While Taylor Lumber was the first independent sawmill to sell power to NS Power, it won’t be the last. The utility’s 2008 RFP calling for 25 MW of biomass power is looking for one big 20 MW project, but also a collection of smaller ones totalling 5 MW, all to replace the province’s heavy dependence on coal. Decisions will be made in mid-2009, so stay tuned. – Scott Jamieson

Print this page