Expanding presence: Alberta companies join forces on drop-in bio-synthetic fuels from residuals

March 5, 2024

By Maria Church

Used CP railway ties are ready for transport to a processing facility. Photo: Expander Energy

Used CP railway ties are ready for transport to a processing facility. Photo: Expander Energy Two Calgary companies have teamed up to introduce bio-synthetic diesel and jet fuel from forestry residuals and other non-food feedstocks to the Canadian and international markets.

Technology provider Expander Energy and Cielo Waste Solutions, a public waste-to-fuel environmental tech company, are ramping up on multiple projects that Expander president and COO Gord Crawford says are filling a growing need for drop-in biofuels made from low-cost, cellulosic feedstock.

Nearly all renewable fuels in Canada are imported and made from food waste and oilseeds, mainly canola. Large, under construction renewable diesel refineries in Canada will also use oilseed as their main feedstock.

“The issue is the bust between the volume of seed oils that can be produced without impacting the food supply and the volume of diesel and jet fuel that are consumed every year,” Crawford says. “We will be producing both paraffinic renewable diesel and Sustainable Aviation Fuel (SAF). We have developed a number of processes to do that from non food competitive waste products.”

In 2022, Expander announced it has third-party verified the Net-Zero or better carbon intensity of its trademarked Bio-SynDiesel®, produced through its enhanced biomass-to-liquids (EBTL™) process.

“Essentially the way we get to a low-carbon intensity fuel is by ensuring that every molecule of carbon in the fuel is short-cycle biocarbon from the atmosphere. We let the plants do all the hard work. We then gasify that biomass and efficiently convert it into a liquid fuel product,” Crawford says.

Cielo CEO Ryan Jackson says the partnership with Expander, anchored by a transaction finalized in November, will allow both companies to accelerate the time to revenue on major projects in the works.

Cielo is now “powered by Expander,” Jackson said. “It’s really a good way to describe what it is we are doing … Expander has market ready technology that we can deploy.”

Expander history

Expander Energy as a company is going on 14 years in the cleantech industry as a biomass to liquid-fuels producer. The company has developed a number of patented processes including a tar-free biomass gasifier which is based on a proven Biomass to Power gasifier that successfully operated in the Czech Republic. Combined with a proven small scale Fisher Tropsch conversion

technology which is in operation at Rocky Mountain Clean Fuels Inc. in Carsleand, Alta., Expander can produce a drop-in bio-synthetic diesel and jet fuel from low-cost cellulosic feedstock.

“History is littered with gasifiers that don’t work,” Crawford says. “Expanders patented 3-stage vertical design operated under EU-certification conditions, over a five-year period, and reliably produced virtually zero-tar syngas. There are a number of technical reasons why it’s significantly different than anything in the market.”

In May, the company partnered with IMG Industries to form Expander Technologies Inc., which will manufacture their patented biomass gasifier. The new company, based in Penticton, B.C., will provide the gasifiers for Expander’s renewable fuels projects. Crawford says the ability to do all of their own engineering inhouse allows them to move the project forward efficiently. Expander did the engineering, procurement, and construction management for Rocky Mountain Clean Fuels’ over $100-million natural gas-to-liquids plant in Carseland, which went into operation in 2022.

The Expander management team brings decades of experience in the development, engineering, construction and operation of energy industry facilities.“To say there are 50 plants that have been built by members of the leadership group is no exaggeration – it’s probably an understatement,” Crawford says.

Expander is in the process of introducing its Biomass to Liquids technology to the Rocky Mountain Clean Fuels’ Carseland location, with the goal of creating a fully integrated commercial biomass to Bio-SynDiesel® facility.

Enter Cielo

As of the November transaction, Cielo Waste Solutions now has exclusive license in Canada to use Expander’s Enhanced Biomass to Liquids (EBTL™) and Biomass Gas to Liquids (BGTL™) technologies, as well as license in the U.S. specific to creosote and treated wood waste. Under the agreement, Expander will handle engineering, procurement, and construction, as well as operation and project management for these Bio-SynDiesel® projects, now owned by Cielo.

“It really did make sense,” Jackson said of the transaction. “We have access to capital markets and there is a need for us to take advantage of the feedstock opportunities that we currently have and are sourcing as a result of this transaction with Expander.”

Cielo’s most notable feedstock opportunity is an existing agreement between them and North American rail company CPKC to turn between 500,000 and one million end-of-life railroad ties into Bio-Synthetic each year. The project, slated for Dunmore in southern Alberta, will now include Expander technology and Expander will design, build and operate the facility.

“You can produce an awful lot of fuel from the fibre that is created from railway ties, and Expander’s technology addresses that in spades. It’s really quite an elegant solution to a very complex problem. Dealing with railway tie disposal is not an easy thing to do,” Jackson said.

Cielo has been a public company for just over a decade. Its own proprietary thermal catalytic depolymerization (TCD) technology is still under development, which Jackson said Expander’s expertise will help accelerate.

Behind the technology

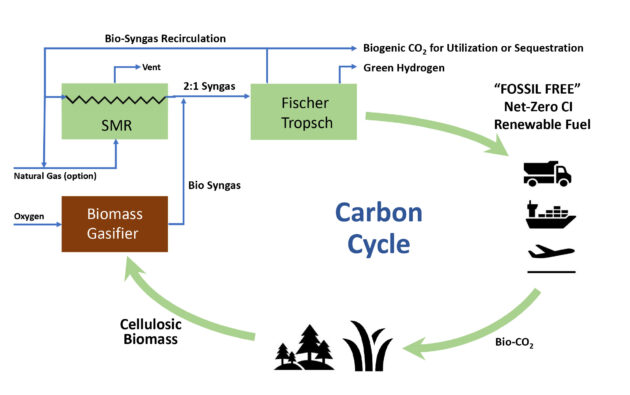

Expander’s Biomass to Liquids processes combine a biomass gasifier with a steam methane reformer, both producing syngas that is upgraded through the Fischer-Tropsch process. Bio-syngas is recirculated in the process, and biogenic CO2 can be captured for utilization or sequestration. Under ideal conditions, which includes carbon sequestration, the resulting Bio-SynDiesel® has a potential life cycle analysis carbon intensity of -44 gCO2e/MJ.

The Carseland project will see a biomass gasifier installed adjacent to the existing Rocky Mountain Clean Fuels facility in Carsleand. The gasifier will take 78 tonnes per day of biomass – landfill debris, forestry and agricultural residue, sewage sludge, and so on – and turn it into hydrogen and carbon monoxide which will then be converted at the existing Carseland Fisher Tropsch facility into 150 barrels per day of Bio-SynDiesel® .

“It’s largely agnostic to the type of feedstock,” Crawford says. “One of the things we will be doing in the first 18 months of operation is running a few selective alternative feedstock campaigns.”

Pending a final investment decision expected soon, Crawford anticipates the Carseland Gasifier Project start-up in early 2026 with market rollout of the technology that same year.

A figure depicting the Expander Enhanced Biomass to Liquids (EBTL™) process.

Pathway to e-fuels

Expander’s next generation biomass electrolysis to liquids (BETL™) technology is in development with Canadian Nuclear

Laboratories in Chalk River, Ont. The technology uses electrolysis of water in place of the steam methane reformer, producing both green hydrogen as a fuel and using hydrogen in the Fischer-Tropsch process along with bio-syngas to produce Bio-Synthetic fuel.

“There’s a lot of interest from the nuclear industry,” Crawford says. “Nuclear can produce grid-level, proven, baseload electricity. But how does that support the heavy transport liquid fuels market? Battery power for small vehicles will continue to roll out, but the concept of batteries for jet aircraft, heavy industrial equipment and things along those lines are far more challenging and further out.”

Growing need

In 2023, the Canadian Council for Sustainable Aviation Fuels (C-SAF) put out a strategy and roadmap for building a feedstocks-to-fuels SAF supply chain in Canada. The council has set an ambitious target of one billion litres of SAF production in Canada by 2030 in order to achieve a 10 per cent share of the projected Canadian jet fuel use.

The roadmap further identifies that, long term, up to 90 per cent of feedstocks should be cellulosic biomass from forestry and agricultural residues, municipal solid waste, and ethanol.

Expander, Crawford says, is among the Canadian firms offering a practical production pathway from those feedstocks. “We have a number of process configurations that allows us to get to 30 gCO2e/MJ or lower, which is equivalent or better than the HDRD [hydrogenation-derived renewable diesel] fuels on the market, using our technology,” he says.

Once Carseland and Dunmore – Projects 1 and 2 – are up and running over the next couple years, Cielo and Expander can build duplicate facilities anywhere the market brings them, Crawford says.

Slave Lake, Alta., is a strong contender for Project 3. The companies are working with Slave Lake-based Vanderwell Contractors to create a large scale EBTL facility alongside their sawmill. The plant will consume 300 tonnes per day of mill residual fibre to produce 600 barrels per day of Bio-SynDiesel®, Bio-SynJet®, renewable naptha and renewable Bio-Wax.

Crawford says Canada’s Clean Fuels Standard, once in place and enforced, will be a boon –

but, despite the Canadian regulations, he says, market forces will dictate demand, which is currently dominated by California in the U.S., and countries in Europe. Canada currently has almost no SAF production, and minimal advanced biofuel production, but plenty of potential.

“Canada can lead in this area,” Crawford says. “Alberta has traditionally had pipelines going south, east and west, producing liquid fossil fuels. What is going to fill those pipelines and supply clean energy as the world becomes decarbonized? There is an opportunity for Alberta and Canada to continue to provide the world with clean, responsible energy.” •

Print this page