Back to the Grind

May 28, 2009

By Canadian Biomass

This grinder update provides an overview of some of the large-scale stationary grinders that are available for processing mill residue, construction debris, and other sources of waste wood into useable biomass or hog fuel. All information has been provided by the equipment suppliers.

This grinder update provides an overview of some of the large-scale stationary grinders that are available for processing mill residue, construction debris, and other sources of waste wood into useable biomass or hog fuel. All information has been provided by the equipment suppliers.

|

|

| The Grizzly Mill boasts metal and rock tolerance and low maintenance costs.

|

CBI’s Grizzly a rugged beast

The CBI Grizzly Mill Hog is designed extremely rugged and will handle almost any material. Cedar bark, green spruce bark, all kinds of mill wood waste, demolition debris, butt ends, railroad ties, and stringy bark are all easily processed, and the resulting product is of high quality and suitable for hog fuel or mulch.

The ergonomic design makes the Grizzly Mill extremely safe, easy, and inexpensive to maintain. Typical maintenance costs for the Grizzly Mill are much lower than for conventional wood waste grinders.

The rugged heart of the Grizzly Mill Hog is an extremely heavy duty, solid-steel, offset helix rotor that shears material from two directions against an anvil and grate. The rotor turns at half the speed of a conventional hammermill rotor, resulting in substantial savings in maintenance costs. The Grizzly Mill is also very tolerant of rock and metal.

The Grizzly Mill is used worldwide in these industries: sawmills, pulp and paper mills, oriented strandboard plants, construction and demolition recycling facilities, log merchandising systems, land clearing operations, compost facilities, and co-generation plants. www.cbi-inc.com

|

|

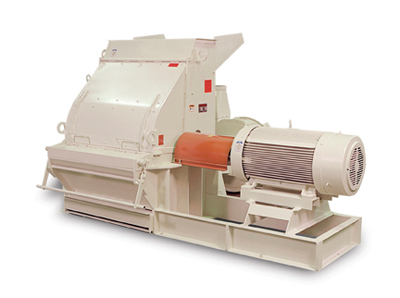

| The Model 15300 Industrial Grinder offers custom configuration and energy efficiency. |

High-volume Hammermill

When your objective is high-tonnage finish-grinding of waste wood with minimal energy consumption, the Model 15300 Industrial Grinder for Schutte-Buffalo Hammermill is your best choice.

Featuring heavy plate construction and internal ribbed liner plates, the Model 15300 is available with the option of gravity or pneumatic discharge. The 72 inch (183 cm) rotor width allows for maximum discharge area. At the same time, the 44 inch (112 cm) rotor diameter provides the tip speed required for high-tonnage throughput using an 1800 rpm motor.

With a wide variety of screens and hammer options, Schutte-Buffalo Hammermill can custom configure a Model 15300 Industrial Grinder to meet your specific needs. www.hammermills.com

|

|

| High-volume processing and ease of maintenance are key features of the Hurricane.

|

Hurricane grinds a swath

Vecoplan offers the unique Hurricane dual shaft shredder. This heavyweight, two-story high machine is designed to process construction and demolition debris, municipal solid waste, plastics, wood, paper, and all types of organic matter. The Hurricane’s throughput of 100+ tons per hour makes quick work of big municipal composting projects, alternative fuel preparation jobs, and large-scale recycling and size reduction needs.

A dedicated drive motor powers each of the Hurricane’s twin cutting rotors. These are available as either hydraulic drive motors or Vecoplan’s patented energy-saving HiTorc electric drive motors. Other features include: hydraulic aggregates with high torque pumps, encased in sound enclosures; a center anvil with a replaceable hard-faced counter knife and removable screen grates for consistent particle output size; hydraulically operated double-wing drop-down doors for easy access to the cutting chamber; and built-in tramp metal protection to minimize downtime.

The Hurricane’s exclusive Closed Rotor design sets it apart, in durability and performance, but more importantly in ease and speed of maintenance, from the open disc, segmented rotor designs found on conventional counter-rotating twin-shaft shredders. Plus, each of the Hurricane’s two rotors is equipped with quick-fix bolt-on cutters that eliminate the need for welding when replacing worn teeth. This cuts routine maintenance time from days and hours to minutes. Access to all wear items is quick and easy without the need for disassembly.

Hurricane Pre-Shredders are offered in six models, VVZ 210 HS, VVZ 250 HS, VVZ 310 HS, VVZ 210 T, VVZ 250 T, and VVZ 310 T, all of which are available in both stationary and portable configurations, assuring a machine that precisely fits the application specifications required. www.VecoplanLLC.com

|

|

| WSM Titan grinders deliver high-volume biomass fuel processing.

|

West Salem Titan in multiple sizes

West Salem Machinery’s (WSM) model 5472BH Titan Horizontal Grinder processes high volumes of stumps, land clearing debris, and urban wood material into biomass fuel for GreEnergy in Thailand.

This stationary electric grinder features dual electric drive motors and a fully proportional hydraulic feed system for efficient processing of diverse feed stocks. The heavy-duty multistrand drag chain infeed and large diameter power feed roll provide superior feeding of large batch loads.

The massive grinder features a 54 inch diameter by 72 inch rotor assembly with rigid hammers and replaceable tips. The 800-hp electric drive system uses dual 400-hp motors for efficient and economical operation. Modular sizing screens ensure a consistent-sized finished fuel product. Machine capacity ranges from 40 to 100 tons per hour, depending on feedstock and finished product size.

WSM Titan Horizontal Grinders are available in a range of sizes, with drives from 500 to 1500 hp. www.westsalem.com

| Regular maintenance is the best troubleshooting for wood hogs Regular inspection and replacement of worn parts can virtually eliminate the need for troubleshooting. Wood hog maintenance can be broken down into critical and noncritical items. Critical items such as rotating assemblies can have an adverse effect on performance of the equipment if not maintained. Noncritical items must be maintained periodically but do not have an immediate impact on performance. Noncritical items include the housing and liners. Both should be inspected and maintained as directed in the operator’s manual. Unless left unchecked for years, neither housing nor liners affect performance or cause unexpected downtime. If inspected and maintained, the housing should last many years. Liners, depending on manufacturer and materials, can last two years. The rotor (including bearings), hammers, and screen grates are critical to wood hog performance. If these are not maintained on a regular interval, you can expect unexpected downtime and performance variations. Hammers and screen grates are wear items and require the most frequent maintenance. If too much wear is allowed, final product quality declines. Typically, hammers wear faster than grates. Wear rate is related to the amount of dirt, sand, and grit in the materials and the hardness of the hammer material. Rotor maintenance must be done regularly on the bearings, the most critical part of the rotor. Bearings may be lubricated with grease or recirculating oil. In either case, keeping the correct amount of oil or grease in the bearing is critical. The most common mistake is overgreasing bearings or not maintaining filters and coolers on recirculating systems, which can cause premature bearing failure. When properly maintained, rotor replacement due to wear is very infrequent. Finally, always follow the manufacturer’s recommendations for safety and maintenance. Tips provided by Jeffrey Rader. www.jeffreyrader.com |

Print this page