Brought to you by Fink Machine, Inc

Fueling the Future: Biomass District Heating in Canada

May 2, 2024 in Features

By Fink Machine, Inc

Selkirk College students from the Plant Operator Program join members of the leadership team and contractors in cutting the ribbon on a new biomass boiler located at the Silver King Campus in Nelson. (Photo: Selkirk College Website)

Selkirk College students from the Plant Operator Program join members of the leadership team and contractors in cutting the ribbon on a new biomass boiler located at the Silver King Campus in Nelson. (Photo: Selkirk College Website) District heating (DH) systems have been long-established in Canada, particularly in large urban settings and on university and college campuses. These systems efficiently heat multiple buildings by utilizing centralized heat generation and distribution networks. In recent years, biomass has emerged as a prominent fuel source for DH systems, offering a sustainable and cost-effective alternative to traditional fossil fuels, especially in smaller, more localized applications.

One of the pioneering biomass-fueled DH systems in Canada is the District Energy system in Charlottetown, owned by Enwave, which has been operational for over three decades. This system serves 145 customers and is fueled by 26,000 tonnes of municipal solid waste and 36,000 tonnes of repurposed biomass annually. It has achieved a remarkable 90% reduction in municipal landfilling volume and has displaced 6.5 million gallons of fuel oil, significantly reducing greenhouse gas emissions. Additionally, for every dollar spent on biomass fuels, 70 cents circulate within the local economy, demonstrating the economic benefits of biomass district heating.

Similarly, Creative Energy has been operating a district heating system in downtown Vancouver for over 50 years. While currently using natural gas, the company is committed to decarbonization in the coming years. Another recent notable example is the Burnaby Mountain District Energy Utility developed by Corix, which utilizes a 13.5 MW biomass boiler alongside a 6 MW natural gas boiler to heat Simon Fraser University and its surrounding developments, covering 5.8 million square feet.

Traditionally, district heating systems focused on reducing energy costs for connected users, leading to large and complex networks driven by economies of scale. However, there’s been a shift towards smaller, more decentralized heating networks driven by the need to lower carbon footprints and promote local economic development. Municipalities and Indigenous communities are increasingly adopting DH systems to leverage existing assets for non-tax-based revenue generation, as exemplified by the City of Richmond’s Lulu Island Energy Company, which reported a significant net income in 2019.

The prevalence of natural gas as a primary fuel for district heating varies across Canada, with regions like Eastern Canada and the Northern Territories facing higher heating costs due to limited access to natural gas. In such areas, biomass emerges as a viable solution, offering a local, low-cost, and low-carbon fuel source. Moreover, biomass district heating supports economic development in rural communities by creating markets for underutilized forest residues and promoting forest management activities.

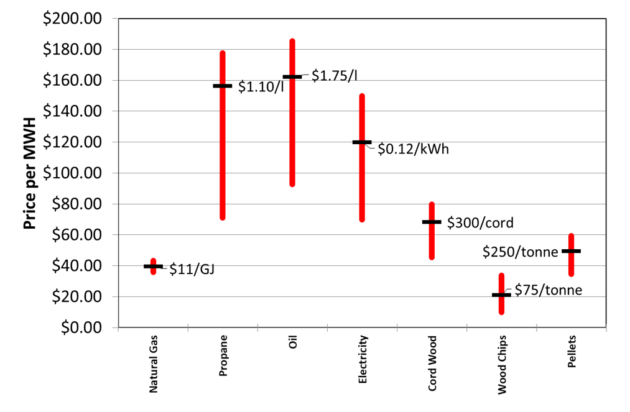

Wood chips and pellets are the primary biomass fuels used in district heating systems, offering lower costs compared to traditional fuels like natural gas, fuel oil, electricity, or propane.

Figure 1 Cost of energy for various fuel types (Image: Fink Machine)

When considering the carbon impacts of biomass, it’s crucial to understand that in Canada, all carbon emissions from biomass are accounted for at the point of harvest as part of the Land Use, Land-Use Change, and Forestry (LULUCF) emissions. This differs from other fuel types, where the carbon footprint is typically assessed at the point of consumption. Furthermore, Canada’s forests are managed sustainably, with harvesting practices mandating replanting. As a result, the carbon emissions associated with biomass primarily stem from the processes of harvesting, processing, and transporting it to the district heat plant. Notably, biomass used in district heating is not specifically harvested for energy but rather arises as a byproduct or waste stream of other primary activities, further contributing to its inherently low carbon nature. While wood pellets boast a higher energy density due to their processing, they do carry a slightly higher carbon footprint compared to wood chips.

Recent examples of small-scale biomass district heating systems in Sicamous, BC, Yellowknife, NWT, and Nelson, BC, highlight the growing interest and success of biomass heating initiatives. These systems not only generate revenue but also reduce reliance on fossil fuels, create local job opportunities, and contribute to community resilience.

Figure 2 Sicamous District Heating System Biomass Boiler (Photo: Fink Machine)

In its initial months of operation, the District of Sicamous system generated $24,364 in gross revenue, with $8,675 transferred to reserves as net revenue. Situated within a new industrial subdivision developed by a private entity, the system utilized a low-value property acquired by the District. This property already had municipal rights of way for sewer and water infrastructure, facilitating the establishment of the district heating network. While currently serving two clients, the District anticipates connecting more as the system gains traction. The District currently sources its wood fuel from Fink Machine but plans to develop its own sources, including those from wildfire mitigation efforts, to further boost revenue. Heating the network is a Viessmann 530 kW biomass boiler, supported by a backup propane boiler.

Another noteworthy instance of small-scale biomass heating is exemplified by the system owned by J&R Mechanical in Yellowknife, Northwest Territories. As a prominent mechanical contractor with experience in biomass boilers, J&R Mechanical embarked on upgrading their own building heating system. Recognizing the potential for collaboration, they engaged the Government of Northwest Territories (GNWT), along with nearby building owners, to explore the feasibility of connecting to a district heating system. This initiative aimed not only to reduce costs but also to minimize carbon footprints, particularly for the GNWT.

Figure 3. Woolgar Avenue district heating system prefabricated boiler plant (Photo: Fink Machine)

Subsequently, J&R Mechanical successfully established the Woolgar Avenue Biomass District Heating network, which they wholly own and operate. With five clients currently connected, the network has significantly displaced 92,000 liters of oil consumption annually, resulting in over 100 tonnes of CO2e emissions reduced annually, and supplies approximately 450 MWh of heat per year. Moreover, this initiative has contributed to the creation of 0.15 full-time equivalent jobs, underscoring its socioeconomic impact on the community.

Selkirk College has taken a significant step towards sustainability by installing a 720 kW wood chip boiler to provide heat across seven buildings at their Silver King Campus in Nelson. This forward-thinking initiative sources its fuel locally from a nearby sawmill, emphasizing the college’s commitment to supporting the local economy. By embracing biomass heating, the college effectively displaces natural gas usage, resulting in substantial cost savings of $15,000 annually. Additionally, the initiative generates $4,000 per year in carbon offset payments and slashes greenhouse gas emissions by a minimum of 50%.

Selkirk College students from the Plant Operator Program join members of the leadership team and contractors in cutting the ribbon on a new biomass boiler located at the Silver King Campus in Nelson. (Photo: Selkirk College Website)

Laura Nessman, the college’s sustainability coordinator, emphasizes the importance of such capital projects, highlighting their dual benefits for the environment and operational budget. She notes, “These are the types of capital projects that make sense, both for the environment and the operational budget.” Nessman further emphasizes how this initiative aligns with several of the United Nations’ Sustainable Development Goals (SDGs), particularly in terms of innovation, climate action, and sustainable consumption. This holistic approach underscores Selkirk College’s dedication to advancing sustainability while achieving tangible economic benefits.

In conclusion, biomass district heating presents a sustainable and economically viable solution for Canada’s heating needs, especially in areas lacking access to natural gas. By leveraging local biomass resources, these systems offer environmental benefits, support economic development, and pave the way towards a greener and more resilient future. As the country continues to transition towards renewable energy sources, biomass district heating stands out as a promising pathway for sustainable heating solutions across diverse communities.