Equipment spotlight: dust collection and suppression equipment 2021

June 21, 2021

By Canadian Biomass staff

A list of the latest dust collection and suppression equipment available for biomass plants

CV Technology

CV Technology is excited to introduce a product to the marketplace that draws upon the company’s 25-plus years of experience with passive flameless explosion protection and allows clients to protect their personnel and process from the effects of a deflagration while simultaneously solving the problem of discharging clean air to the exterior of their facility. With the Interceptor-QV, wood product facilities get the protection they need while safely and efficiently returning clean air to the facility, thereby reducing HVAC costs and building air make-up issues. Another patented feature of the Interceptor-QV is an integrated thermocouple, which, when exposed to the intense heat of a deflagration, will indicate, via relay, that the system has been involved in an event. A passive system like this is on the job 24 hours a day, 365 days a year. There is nothing to arm and no power source required for the QV to do its job.

VETS Sheet Metal

VETS Sheet Metal was founded in 1921 by a World War I veteran and has nearly 100 years of HVAC experience. The company completes projects in industrial, light industrial and institutional HVAC capacities with a specialization in dust collection and pneumatic conveying. Every application requires a unique approach to the development and implementation of a dust system. Whether the best tool for the job is a traditional cyclone or baghouse or something more unique like a Multi-Cone or Cyclofilter VETS can engineer, design, fabricate and install a system that meets or exceeds your plant’s safety and environmental requirements.

Rembe

Innovative technology makes it possible to divert combustible dust explosion shock waves and flames in a controlled manner so the required safety area is reduced, valuable usable area is increased and personnel/equipment are protected from the explosion’s effects. Explosion vents are an economical form of explosion pressure relief but require extensive safety areas that become unusable space. Rembe’s Targo-Vent is an opening angle limiter developed especially for Rembe explosion vents. Targo-Vent guides pressure relief into areas where there is no danger to infrastructure or personnel. Targo-Vent absorbs the enormous repulsive forces of explosion energy and guides the flames/shock wave in the desired direction so usable area is increased.

IEP Technologies

IEP Technologies provides a complete range of cost-effective industrial explosion protection for biomass applications and is pleased to introduce the IV8 Flameless Vent. The IV8 provides an explosion protection solution for process vessels which are located inside a building or other areas where standard explosion venting cannot be safely employed. The IV8 utilizes a stainless-steel explosion relief vent and flame arresting mesh enclosed in a durable carbon steel-coated frame. The integrated vent burst detection sensor allows plant personnel to respond accordingly in the event of an explosion within the protected application.

Fike

Fike DFI is an ultra-reliable, compact passive explosion isolation valve that’s tested and proven to perform accurately under pressures it might experience during a deflagration within a biomass application. Its lightweight dual-flap assembly allows it to be installed near a vessel and in both vertical and horizontal orientations for sizes up to DN800. DFI exceeds the current EN16447 standard which has been empirically proven to not fully represent real-world applications. For instance, the standard allows for test setups to not include a “protected zone pipeline” on the non-deflagration side of the flap valve. Without it, the flap valve may be certified to protect against pressures for which it hasn’t been accurately tested.

Kice

Kice Industries has introduced a new baghouse filter to its product line, the Kice GR Filter. The new and improved design will result in lower energy consumption and extended filter bag life. The new filter contains a patented auto-timing mechanism that does not require mechanical adjustment to ensure proper reverse air timing for cleaning. It has a standard temp rating of 150 degrees F with a max temp option up to 300 degrees F. The filter also has low energy requirements with a 7.5-hp reverse air cleaning blower.

BossTek

As effective dust control continues to gain priority across a wide range of industries, a new equipment design has been engineered to provide an unmatched level of mobility and performance, delivering effective particle suppression for new and existing applications. The DustBoss Atom from BossTek is a fan-less, self-contained unit that incorporates remote control and 4G LTE telematics technologies to deliver an unprecedented combination of suppression and monitoring. The Atom is well-suited to biomass handling, bulk material processing, demolition projects, recycling operations, transfer stations, ports/shipping applications, quarrying/crushing, concrete curing and even indoor operations where significant air movement may be undesirable.

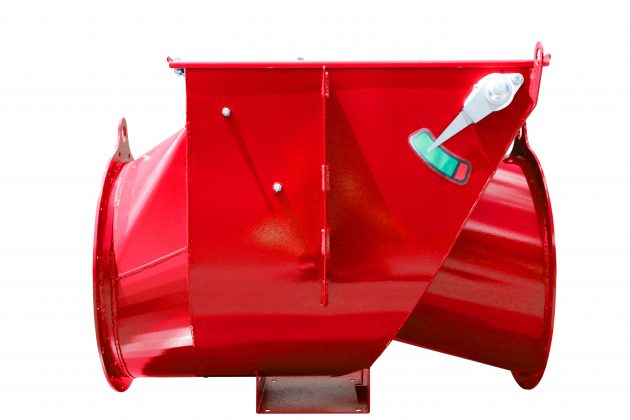

Allied Blower

For wood processing facilities demanding larger system capabilities, Allied Blower & Sheet Metal has a certified line of Back Blast Dampers (BBD’s) that reach sizes up to 50 inches in diameter. The BBD can resist a vented dust collector explosion reaching a Pred of five psi (0.35 bar) for dusts with a Kst of up to 200 bar-m/second. This range provides safe operation for a large range of deflagrable dusts used in industry. When comparing the options of using a passive mechanical system or an active chemical suppression system, the mechanical systems are perceived to have less maintenance costs due to simplicity in function, design, training requirements, and the low frequency of inspections. With a mechanical BBD, mill staff do not need specialized training or tools when inspecting and keeping maintenance records for NFPA compliance, as they would with an active chemical system. This results in more up-time, allowing for increased production. Allied’s BBDs are built in Canada and designed for easy installation, inspection, and maintenance. The instrumentation meets North American standards to easily integrate into a plant or mill PLC system and is available in Class 2 Div 2. A combination of Allied BDD and an Allied’s NFPA certified rotary feeders can provide NFPA-compliant passive isolation for large sized systems.

Boss Products America

The EV-VF VigiFlap explosion isolation valve has been designed, tested and certified to prevent the propagation of overpressure or flame front caused by a potentially catastrophic explosive event. Intentionally certified for “Intended Use,” the VigiFlap valve has been proven to function flawlessly when tested for dust collection suction and pressure side ducting installations. The VigiFlap’s unique inlet/outlet straight through design has proven to be a superior product for applications that require installation with elbows, vertical/horizontal piping installations, very low-pressure resistance and zero dust accumulation. All VigiFlap explosion isolation valves are 100 per cent NFPA-compliant when ordered with the CP04 intrinsically safe control panel and dust level sensor.

AFS Energy

AFS Energy offers a rough mill 65,000 filtered dust collection system, featuring pre-cleaning cyclones with a closed-loop pneumatic material transfer ductwork, spark detection and extinguishing system, and pneumatic material transfer system. The company has installed he system at Peerless Bin, with plant return air ductwork with summer/winter dampers.

Print this page