Key takeaways from WPAC’s bow tie analysis workshop

November 25, 2019

By The Wood Pellet Association of Canada

The Wood Pellet Association of Canada (WPAC), in co-operation with WorkSafeBC and media partner Canadian Biomass, held the Process Safety Workshop on Bow Tie Analysis at the Prince George, B.C., Civic Centre on Nov. 13, 2019. Fifty participants, including pellet plant operators, maintenance personnel, and representatives from insurance companies, universities, fire detection equipment suppliers, and WorkSafeBC, attended the event. The workshop was facilitated by WorkSafeBC’s Jenny Colman, ergonomist/human factors specialist, Mike Tasker, occupational safety officer, Geoff Thomson, occupational safety officer and Jennifer Fung, senior engineer.

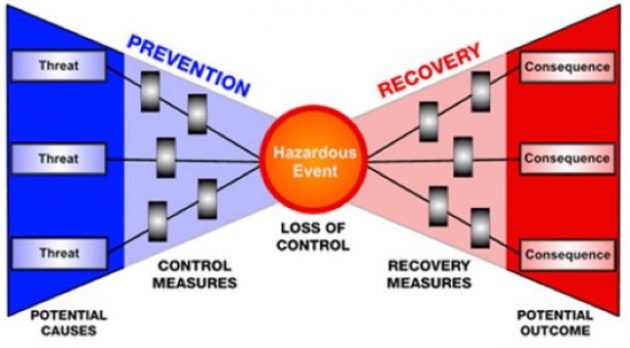

Bow tie analysis is a method of predicting all the potential causes of catastrophic incidents and putting in place critical controls to prevent such catastrophes from occurring. The bow tie visualizes the relationship between an undesirable event, its causes, accidental scenarios, and the preventive and mitigation measures to limit their consequences. It also demonstrates the effectiveness of existing controls.

The workshop started with an introduction to bow tie analysis, followed by hands-on experience for all participants. They worked in small groups (under the direction of WorkSafeBC facilitators) to develop bow ties for some of the largest potential catastrophes that could occur in any of our plants:

- Combustible dust explosions at the size reduction hammer mill equipment/pelletizing equipment

- Combustible dust explosions in conveyance (any after the dryer)

- Fire within a belt dryer

- Combustible gas explosion in a dryer or in the system downstream of the dryer/ID Fan failure

Jenny Coleman (left) and Geoff Thomson facilitate one of the groups developing bow ties for some of the largest potential catastrophes.

Jennifer Fung (left) and Mike Tasker facilitate the other group developing bow ties for some of the largest potential catastrophes.

As seen in the figure below, in the centre of the bow tie is ‘hazard,’ which is an operational activity or materials that have the potential to cause harm. The hazard could lead to the ‘top event.’ The top event is the moment when control over the hazard is lost, releasing harmful potential. On the right side of the bow tie are ‘consequences’ that are direct outcomes of an accident sequence that results in harm. ‘Threats’ are also listed on the left side. They are initiating events that can potentially release a hazard and produce the top event. ‘Controls’ are listed in between the threat and hazard, as seen in the figure below.

Figure 1

Though they are extremely important, critical controls can fail. Consequently, continuous inspection, maintenance and training is very important. One way for getting the right level of detail for controls is to make sure they follow the ‘detect, decide and act’ guideline. Diversity of the team is also critical for a successful bow tie analysis.

Examples of developed bow tie analyses can be found here: Developed Bow Tie Analyses.

Download the full presentation from WorkSafeBC here: WPAC Bow Tie Analysis presentation.

Next up: WPAC is planning a Human Machine Interface (HMI) workshop to be held in Q1 2020. Stay tuned!

Print this page