Pelletization: An under-appreciated, key component of the Canadian bioeconomy

August 14, 2020

By Mahmood Ebadian, Shahab Sokhansanj, Jack Saddler – The University of British Columbia

High-capacity storage, handling and transportation operations have made the mobilization of over 40 million tonnes of wood pellets a cost-efficient and effective solution for de-carbonizing power and heat sectors. This photo shows Pinnacle's wholly-owned Westview terminal in Prince Rupert, BC. Photo credit: WPAC.

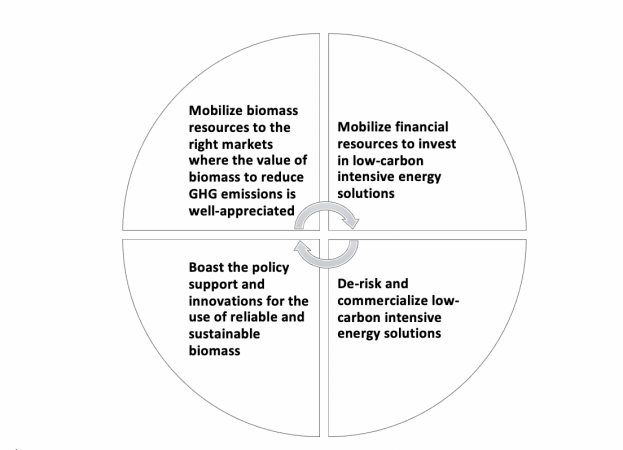

High-capacity storage, handling and transportation operations have made the mobilization of over 40 million tonnes of wood pellets a cost-efficient and effective solution for de-carbonizing power and heat sectors. This photo shows Pinnacle's wholly-owned Westview terminal in Prince Rupert, BC. Photo credit: WPAC. One of the key components of the evolving Canadian bioeconomy is not just the creation of new conversion technologies but rather finding ways to sustainably access and distribute Canada’s bountiful biomass resources. Mobilization of biomass resources in a cost-efficient way to produce low-carbon intensive bioenergy, biofuels and bioproducts should be a win-win for both humanitarian and commercial ventures. Using enabling technologies such as pelletization to mobilize millions of tonnes of biomass can enrich the world socially and environmentally, and benefit many people economically, especially in rural communities.

Pelletization has already led to the creation of world-class supply chains. Over 40 million tonnes of wood pellets annually are transported to regions where the value of biomass to reduce GHG emissions is well-understood and appreciated.

Since the mid-1990s, Canadian wood pellet companies have employed this enabling technology in making local biomass resources available to the heat and power markets. In particular, coal-fired power plants have turned to biomass to produce low-carbon intensive electricity while creating jobs and economic activities in the wood pellet value chain. The successful contribution of wood pellets to displace about 20 million tonnes of coal in countries such as the UK has encouraged more countries and regions to consider developing supporting policies for the use of sustainable and renewable biomass resources to displace fossil fuels including coal, propane, heating oils, diesel and natural gas. The Canadian wood pellet industry has established an international reputation for secure and reliable supply of sustainable wood pellets and set a successful example in the sustainable development of the bioeconomy.

Secure and robust mobilization of biomass resources by pellet producers have also resulted in the mobilization of financial resources to invest in the establishment of world-class supply chains in Canada including railcars, shortline railroad, port facilities and ocean shipping. The Canadian pellet industry has invested nearly $1 billion in the establishment of pellet plants and the downstream supply chains, and created about 1,500 direct jobs in the Canadian wood pellet value chain. Large Canadian pellet companies now have the capability to establish and commission a large-scale pellet plant (>100,000 tonne/year) in about a year. In addition to pellet suppliers, some of the coal power generators such as Drax have invested in railcars and railroad to reduce wood pellet supply chain emissions and costs. On the upstream side, local forest harvest companies are investing in biomass logistics equipment such as grinders, chippers and trucks to meet the increasing feedstock demand of the pellet plants in Canada.

The world-class wood pellet supply chains in Canada can also reduce the risk of securing capital for feedstock users as they can demonstrate the security of feedstock supply from reliable wood pellet producers to their lenders and investors. Canadian pellet producers’ reputation for supplying commercial quantities of sustainable wood pellets has helped power plants start displacing coal with wood pellets as an economically and environmentally sustainable business case. They have also begun adjusting their investments to retrofit their power plants and to mitigate the risk of their stranded assets due to the global pressure for a fossil fuel phase out.

Contribution of Canadian wood pellet industry to a sustainable bioeconomy

Other values that the Canadian wood pellet industry are contributing to the development of a sustainable bioeconomy include:

- Feedstock supply security: Pelletization makes the use of high-capacity transportation modes such as rail and ocean vessels economical. As a result, in addition to the local biomass resources, biomass users will be able to procure their required feedstock from other regions. This gives them more flexibility to meet their annual biomass demand and negotiate on the biomass price. The high-capacity transportation modes also streamline the inventory management as each feedstock delivery load can procure several hundred tonnes of feedstock.

- Inventory management: Wood pellets have longer shelf lives compared to unprocessed biomass. In addition, wood pellets are stored in storage silos with controlled storage conditions, minimizing the degradation of biomass quality. Higher bulk density and the uniform size and shape of wood pellets allows for an optimized storage regime and lower land requirements. This enables biomass users to store commercial quantities of wood pellets on-site, reducing the risk of supply shortage.

- Design of the receiving and pre-processing system: the selection and design of the receiving and pre-processing system at the conversion facility impact the economies of scale since the facility may not be able to reach its rated capacity due to a low-capacity and under-designed receiving and pre-processing system, a pain point experienced by pioneering advanced biofuels plants using unprocessed biomass as feedstock. The uniform size and shape of wood pellets with predictable physical and chemical properties streamline the design of the receiving and pre-processing system and allows for the use of high-capacity handling and receiving equipment, as is being done in coal-fired power plants using wood pellets.

- Economies of scale: Uniform size and shape of wood pellets, using high-capacity transportation modes, and improved handling and inventory management practices enable conversion facilities to take advantage of the economies of scale by creating a reliable and efficient flow of commercial quantities of feedstock from biomass resources to the throat of their conversion reactor.

- Location of bio-conversion facility: Wood pellets can be transported over long distances using rail/water transportation modes in a cost-efficient manner, giving conversion technology project developers flexibility to find an optimal location for their facilities.

High-capacity storage, handling and transportation operations have made the mobilization of over 40 million tonnes of wood pellets a cost-efficient and effective solution for de-carbonizing power and heat sectors. This photo shows Pinnacle’s wholly-owned Westview terminal in Prince Rupert, BC. Photo credit: WPAC.

Despite the continuous success of the Canadian wood pellet industry in helping other jurisdictions meet their GHG emissions reduction goals, the use of sustainable wood pellets and other under-utilized biomass resources in the production of low-carbon energy is still very limited in Canada. A cost-efficient and effective mobilization of biomass resources using pelletization for bioenergy production is a shovel-ready solution for federal and provincial governments to recover their economies while meeting their climate change and GHG emission reduction goals. This requires supporting policies and regulations that encourage the production and use of low-carbon intensive heat and electricity. This also paves the way for the future use of biomass for other applications such as biofuels and bioproducts as regional pellet supply chains are developed in Canada and conversion technologies are commercialized and mature.

We need to keep in mind that pelletization is not only the act of densifying biomass into higher density feedstock. It is a solution to the current challenges of mobilizing biomass resources to meet the quality and quantity needs of the existing and emerging conversion technologies.

Print this page