20/20 hindsight: 5 biomass boiler blunders and what I’d do next time

May 9, 2023

By Grant Rawcliffe

Sponsored

Heizomat Canada’s Grant Rawcliffe shares 5 things he’d do differently after 9 years operating a biomass boiler and supporting customers.

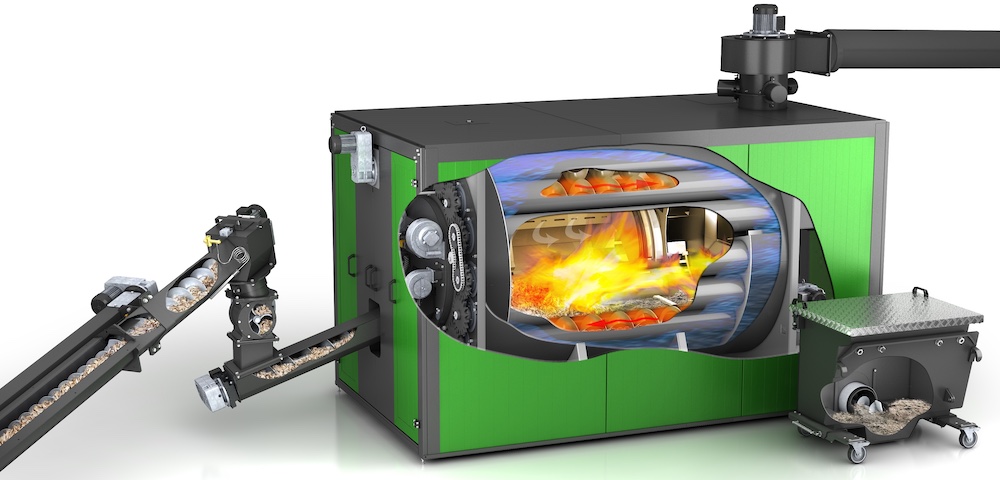

Photo: Heizomat Canada

Photo: Heizomat Canada So, it turns out, I’m not perfect and I don’t always get it right the first time. But, on a positive note, there’s nothing quite like being able to give our customers advice based on first-hand experience (aka screw ups).

So, here are a few bioheat lessons that will hopefully help you avoid my pain and get straight to enjoying the benefits of low-cost, automated, planet-friendly heat.

The big bolt blockage

There’s a lot of talk in the biomass community about fuel quality and the need for perfectly sized fuel. This is a challenge in Canada because, despite the abundance of low-cost waste wood, the demand and therefore the supply chain for biomass-quality fuel is not really here yet.

An embarrassing collection of treasures from our boiler ash. Photo: Heizomat Canada.

This is why we chose to bring Heizomat boilers to Canada (wink wink). Their robust feed system is designed to handle oversized fuel making it easier to burn the low-cost waste wood that is so readily available.

Obviously, I had to test it.

A truck load of tub-grinder chip was acquired from a local recycler and the red flags started flying when a hydraulic cylinder fell out during unloading. Visions of dark cold nights digging out a bunker jam danced through my head, but surprisingly, never came to fruition.

It was actually the ash auger that jammed, courtesy of a 5” long ½” thick bolt. While it didn’t shut the boiler down, it did take some time to clear the jam. And I was actually pretty impressed that such a large bolt made it all the way through the feed system and fire chamber before jamming in the ash bin auger, especially since this was on a small, 100 kW (338,000 Btu/hr) boiler. It wouldn’t have even bothered a bigger boiler with a bigger ash auger.

Suffice to say, bolts don’t make great fuel and can potentially cause big trouble for boilers that are not built to handle them.

Clinkergate

In addition to bolts and chunks of metal, the chip from the recycler also had other contaminants that ended up causing the ash to stick to the fire bricks and form large slabs of very solid (tarmac-like) clinkers.

Luckily, we had a chain grate biomass boiler designed to handle clinkers, but the sheer number, size and density of them was still too much for our little boiler. Cleaning of the fire chamber went from twice-a-season to weekly and required the aggressive use of Thor’s hammer and a poorly paid student to take care of it.

This is not a lesson I am interested in repeating, and so my highest recommendation is to avoid contaminants wherever possible, especially acidic ones (glues, treated products, fertilizers, etc.) as they can be corrosive and shorten a boiler’s life. Make sure you ask a boiler supplier for advice on your proposed fuel before you try burning it.

The chimney fire

We are regularly asked if our boilers can handle green or wet fuel. And while we could technically say that it’s possible, we strongly discourage it for many reasons, the simplest being that water just doesn’t burn. The wet fuel has to be dried before it can ignite and all the heat used to evaporate the water is wasted, significantly reducing the power output of the boiler (in some cases by half or more).

But we still decided to test how bad it would be by burning wet fir chips for three weeks. We ramped up the air supply and ramped down the fuel feed rate to get a semblance of a fire (and a whole lot of smoke) and, as expected, the result was a lower heat output and a more inconsistent fire that required daily attention.

Simple chip drying in an overhang (toys optional). Photo: Heizomat Canada.

What we didn’t expect was that after switching back to dry fuel we had a chimney fire. The increased moisture and lower temperatures of the flue gases from the wet fuel caused creosote build-up that ignited when burning the dryer fuel. Luckily the boiler sensors survived and the only damages were to the paint on the flue gas blower …and our ego.

Wet fuel not only reduces heat output, increases smoke and causes destructive chimney fires but it can also shorten the life of your fire bricks and significantly increases maintenance. If you have wet chip and want the best bioheat experience it’s actually really easy to dry the chip. Just protect the chip from the weather (even a tarp will do), allow some natural airflow and no matter what size the pile is, it will only take two to four months to dry enough for burning (20 to 25 per cent moisture content).

If you are left with no option but to burn wet fuel for a short period of time then be sure to increase the frequency of the automatic heat exchanger cleaning and regularly monitor the creosote build-up in your flue gas blower and chimney. Clean it as often as needed. Then do a really thorough cleaning before you switch back to dry fuel.

The bunker jam

Chain conveyor in bunker easily handles a 2×4 block. Photo: Heizomat Canada.

No, this jam wasn’t a test and it surprisingly wasn’t caused by the recycled chip. It was fuel from a lumber yard we regularly use but a section of their chipper screen had been damaged and allowed some big chunks through. Almost all of the chunks made it into the boiler without issue, but one particularly big and stubborn hardwood knot didn’t, and we had to dig through the bunker to free it.

Again, this was on a smaller boiler that has a 6” feed auger. It would not have been an issue for an 8” or 10” auger or a chain conveyor (which can handle pop can sized objects). In this case bigger is definitely better and we always recommended a bigger auger or chain conveyor if you might have oversized fuel or fuel with gravel, bolts or other unfriendly stuff in it.

The shutdown curse

I cannot lay claim to this one, it was actually a customer. They shut their boiler down in spring without doing the recommended pre-shutdown maintenance. This consists of simply running the heat exchanger cleaning, running the deashing systems to remove the ash from the boiler, emptying the ash bin and then cleaning the flue gas blower and chimney. It takes less than an hour to do.

The summer humidity turned all that light dusty ash left in the boiler sticky and moisture that got into his outdoor ash bin turned into a solid mess that jammed the ash auger. A simple maintenance job turned into an epic half day project and a hard-learned lesson that our advice might have some merit after all.

The secret to a forgettable boiler

I love being able to forget about my boiler and have it just work without my constant attention (to the point where I often forget to fill the bunker). But it does take a bit of planning to get it to a point where it is truly hands off.

I’ve put together another short article on ‘5 Tips for a Truly Hands-Off Biomass Boiler’ that you might enjoy and please feel free to give us a shout if you’d like some advice, have questions or want to share your own bioheat adventures.

You can reach us at 1-844-983-3494 or www.heizomat.ca/contact and you can take a virtual tour of a working boiler at www.heizomat.ca/boilertour.

Grant Rawcliffe is a key member of the Heizomat Canada Inc. leadership team with responsibilities in marketing, sales and technical support.

This article is part of the Bioheat Week 2023. Read more articles about bioheat in Canada.

Print this page