Request for information: how to integrate mobile pellet systems with farm operations in Canada

September 10, 2020

By Mahmood Ebadian, Shahab Sokhansanj

The existing infrastructure and human capital in the agriculture sector can be leveraged to establish cost-efficient ag-pellet supply chains and mobilize underutilized biomass resources in Canada. Photos courtesy 4Peaks, Didsbury, Alta.

The existing infrastructure and human capital in the agriculture sector can be leveraged to establish cost-efficient ag-pellet supply chains and mobilize underutilized biomass resources in Canada. Photos courtesy 4Peaks, Didsbury, Alta. The Biomass and Bioenergy Research Group (BBRG) at the University of British Columbia is seeking information from pellet mill manufacturers and farmers on the small-scale pellet units with the capacity of less than one tonne per hour (1000 kg/hr). The wide spread of crop fields and the high capital cost of farm equipment has made the mobilization of farm equipment among crop fields a common practice. BBRG intends to develop a mobile pellet system that can fit into the current business models of custom operators in Canada. The proposed system that would eventually operate similar to custom combine and baling would pelletize crop residues and biomass crops into pellets. In this system, the produced pellets are stored in hopper bottom bins on the farm similar to grains. The pellets are then sold for various applications or trucked to a central depot similar to grain elevators for shipment to port terminals for exports to regional and international markets.

The existing infrastructure and human capital in the agriculture sector can be leveraged to establish cost-efficient ag-pellet supply chains and mobilize underutilized biomass resources in Canada. Photos courtesy 4Peaks, Didsbury, Alta.

Ideally, the mobile pellet system can be installed in a 20- or 40-foot container. The mobile pellet system could be a turnkey solution that includes all the necessary operations to produce durable ag-pellets such as feeding storage, pre-conditioner, hammer mill, cyclone, buffer, pellet press and cooler. The development of a means of commercializing ag-pellets is part of a four-year project that BBRG is leading with financial support from Agriculture and Agri-Food Canada’s AgriScience Program and in collaboration with the Wood Pellet Association of Canada (WPAC) and BiofuelNet (BFN). The overall objective of this project is to develop a mobilization strategy for under-utilized biomass resources in Canada to commoditize biomass for bioenergy, biofuels and bioproducts in the wake of supporting policies such as Clean Fuel Standard in Canada that encourages the use of renewable and sustainable biomass resources for the production of low-carbon intensive bioenergy and biofuels. The project team is also looking into the integration of ag-pellet supply chains with the existing grain and wood pellet supply chains to stretch the access of Canadian ag-pellets to the regional and international markets. More information about this project can be found here.

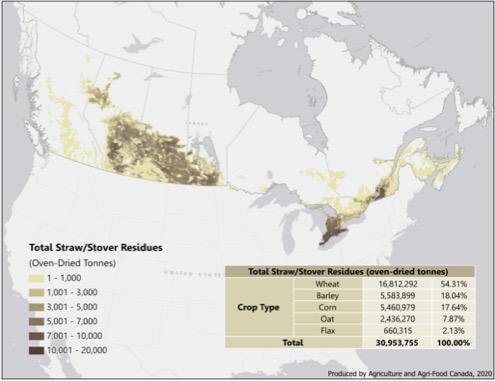

On average, about 31 million dry tonnes of agricultural residues (e.g. wheat, barley, corn, oat and flax) are produced annually in Canada. Although a portion of these residues are used for local animal feed and bedding markets, a majority of these resources are currently underutilized or burnt in the field. Making agricultural biomass available to local, reginal and international markets allows farmers and custom harvest groups to maximize the return on the renewable and sustainable agricultural biomass resources in Canada.

Annual regional production of agricultural biomass resources in Canada.

(Map from Alyssa Klein and David Lee, Biomass Inventory Mapping and Analysis Tool, AAFC).

Once the small pellet system is adopted and become a mature farm operation, the potential economic activities and local employment opportunities would be significant due to the large number of logistics operations involved. To put these potential opportunities into perspective, the Canadian pellet industry with a total production capacity of over four million tonnes/year has invested nearly $1 billion in the establishment of pellet plants and downstream supply chains, and created about 1,500 direct jobs in forest communities. The commercialization of ag-pellets in Canada will likely increase the demand for agricultural equipment such as balers, baler collectors, loaders and trucks. Agricultural equipment manufacturing is a growing industry in Canada, with revenues averaging just over $3 billion per year1. The development of local and regional ag-pellet businesses also provides an opportunity for equipment dealers to provide sale, maintenance and repair services for the owners of the small pellet units.

BBRG is inviting interested pellet mill manufacturers to provide technical and economic information on their small-scale pellet units with the capacity of less than one tonne per hour (1000 kg/hr). The BBRG team will collect and compile the information on the existing small-scale pellet mills that can be mobilized to pelletize agricultural biomass in Canada. In the next step, the BBRG intends to identify the mobile pellet systems that have proven pelletization capability to produce durable and dense ag-pellets and introduce these mobile pellet systems to Canadian farmers and custom operators. The final goal of this study is to provide a well-founded base of information for farmers and custom operators to invest in small-scale pellet units to support the valorization of agricultural biomass resources in the evolving Canadian and global bioeconomy.

Companies who are interested in participating in this study can contact Mahmood Ebadian at mahmood.ebadian@ubc.ca to learn more about the project and provide the requested information on their small-scale pellet units. Any shared information will be treated in confidence by the project team.

Notes

1. Agricultural Manufacturers of Canada (AMC) – www.a-m-c.ca/industry

The Biomass and Bioenergy Research Group (BBRG) is a world-class research group, based at the University of British Columbia. The Group conducts advanced research and develops innovative solutions to meet the needs of the emerging biobased businesses in Canada and around the world. BBRG is made up of a core group of engineers and scientists focused on turning raw biomass to industrial feedstock that would meet the requirements of producing high value intermediate chemicals and biofuels. The main technical activities of the group consists of evaluating the physical and chemical properties in relation to biomass size reduction, drying, pelletization, and best practices for safe handling and storage of biomaterials. The group has also unique expertise in developing mathematical models for conducting feedstock supply chain simulations and techno economic assessments.

Print this page