Why humidity measurements are crucial in harnessing the true power of biogas

October 17, 2023

By Antti Heikkilä

Sponsored

Photo: Vaisala

Photo: Vaisala Between government policies, shifting consumer demands and technological innovation, Canada’s renewable energy landscape is set for massive expansion in the years to come. With the world transitioning to a greener, cleaner and more sustainable future, much of the focus is rightfully placed on wind and solar projects, but biogas is gaining traction in the Canadian market and globally as a potent and sustainable power source.

Biogas holds a distinct advantage over other, more well-known renewable energy sources due to its reliability and storage capacity. However, the production of energy from biogas and biomass is subject to many variables – especially humidity. Between calculating methane volume and determining the frequency of changing carbon filters, understanding how humidity impacts the biogas production process helps ensure maximum project efficiency and profitability.

Consequently, technological developments and advanced plant designs increasingly create avenues for more efficient bioenergy capture and production, boosting the number and efficiency of clean energy projects across Canada and globally. From producing biogas to upgrading it to biomethane/renewable natural gas, Vaisala’s biogas production solutions help pave the way to a greener future at every stage.

How humidity impacts biogas production

High humidity affects the generation of bioenergy in myriad ways:

- Reduced yield.

- Corrosion and equipment damage.

- Difficulty regulating temperature.

- Safety and quality regulations adherence.

With research confirming that high moisture content wastes are “more compatible with conversion by anaerobic digestion, landfill, and digestion technologies,” maintaining the correct moisture content is crucial for optimizing biogas production efficiency. Excessively high humidity levels can lead to too much moisture in the feedstock and the digester, which creates an environment conducive to spoilage microorganism growth. These microorganisms compete with methane-producing bacteria, preventing the bacteria from effectively breaking down organic matter and reducing biogas yields. Additionally, high humidity can pose challenges in maintaining the quality of biomethane.

In environments with low humidity, microbial activity slows, resulting in a longer retention time for the feedstock in the digester and a reduced biogas production rate. Low humidity conditions can also lead to inhibitory compound accumulation within the digester, harming the methane-producing bacteria. These environments might also demand energy-intensive humidification, which increases operational costs and reduces the project’s overall energy efficiency.

In addition to affecting gas yields, nonoptimized humidity levels can lead to corrosion and equipment damage. Excessive moisture in the air can interact with metal components, resulting in rust and other damage that decreases the lifespan of equipment, increases maintenance costs and ultimately hinders biogas production system reliability. Even worse, low humidity can lead to drying and cracking of the digester walls and seals, contributing to gas leaks, potential safety issues and equipment damage.

Since microbial growth efficiency depends on maintaining consistent temperatures, any fluctuations in humidity levels can make controlling the temperature difficult, hindering successful biogas production.

As the Canadian biogas industry continues expanding and contributing to the country’s renewable energy goals, addressing humidity-related challenges is a priority. Enter the Vaisala CARBOCAP® MGP261 Multigas Probe for Methane, Carbon Dioxide and Humidity.

Smart control of biogas quality

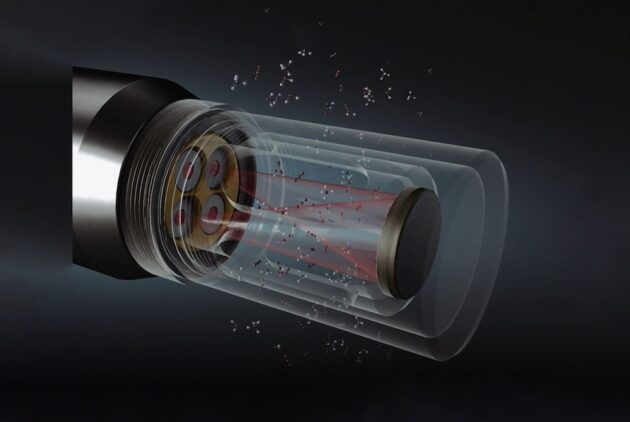

Designed for in situ measurements in demanding biogas processing conditions where repeatable, stable and accurate measurement is essential, this unique multigas probe is Ex certified for use in Ex Zone 0 (parts inserted into the process) and Ex Zone 1 (parts outside of the process).

MGP261 continuously measures methane, carbon dioxide and humidity – which comprise the bulk of biogas – to provide a comprehensive picture of the process. With internal temperature measurement for compensation purposes and an option for external pressure or temperature compensation input, the patented measurement gives unparalleled stability and reliability without calibration gases. The MGP261 measures gases directly in the process pipeline without needing moisture removal, simplifying in situ measurements.

MPG. Image: Vaisala

The benefits of continuous humidity monitoring

Continuous humidity monitoring is a lesser-known but highly impactful tool in the biogas producer’s tool belt, offering many benefits beyond mere moisture control.

- Calculate accurate humidity levels and methane volumes to optimize biogas quality and energy yield.

- Enable real-time adjustment to adapt to changing environmental conditions.

- Extend carbon filter lifetimes by maintaining optimal humidity levels.

- Better manage operating expense costs by improving processes.

- Improve safety by preventing humidity-caused damage to equipment and infrastructure.

- Meet regulatory requirements for biogas quality and emissions.

- Minimize the industry’s environmental footprint and better align with Canada’s sustainability goals.

As renewable energy continues moving into a more efficient, sustainable and profitable space, continuous humidity monitoring via instruments like the Vaisala MPG 261 helps ensure biogas makes a more significant impact in advancing the nation’s clean energy revolution.

Monitoring humidity across the biogas generation process

From anaerobic and microbial digestion to biogas collection and impurity removal, humidity management is vital to ensure efficiency and sustainability at every stage of biogas production.

Heat exchangers

Heat exchange dryers play a crucial role in biogas production, recovering waste heat produced during anaerobic digestion to utilize across various applications, such as space heating, water heating or process heating nearby facilities or industries. Typically located downstream from the anaerobic digester, heat exchangers cool gases to the same temperature as their coldest part, dropping the dew point to the same temperature.

Consequently, measuring the dew point after cooling is the only reliable way to know the humidity content. Monitoring and controlling the humidity levels in the heat exchanger and the material or gas being treated will optimize the performance of the biogas generation process.

Active carbon filtration

With studies exhibiting a solid link between relative humidity of gas and filtration efficiency, finding the optimal level for your system is critical. Active carbon filtration systems purify the biogas by removing contamination, such as hydrogen sulfide, siloxanes and other volatile organic compounds.

Any excess moisture on the carbon filter media can negatively affect its absorption capacity, while too dry an environment alters carbon’s structure, significantly diminishing active filtration efficiency. Maintaining a relative humidity level between 50 per cent and 70 per cent is recommended for optimal outcomes. One activated carbon refill can be up to €4,000 (CA$5,750), depending on the filter type and size. As a result, improper humidity management can double the lifetime cost.

Combined heat and power (CHP) engines

Typically connected to the biogas collection system, CHP engines are crucial in converting biogas into electricity and heat. Using biogas as fuel to generate electricity, CHP engines are sensitive to humidity, with dry gas containing more energy per volume than wet gas.

High humidity causes moisture condensation in the engine’s air intake system, hindering performance and increasing the likelihood of corrosion and worn engine components. If water enters a medium-sized engine, the $5,000 daily cost of lost production is insupportable. Even if the engine doesn’t stall, high humidity increases maintenance needs and associated costs.

With that understanding, reducing humidity in a 1-megawatt CHP engine by one volume per cent can increase the heat content of the gas by one per cent.

Continuous humidity monitoring costs significantly less than the combined costs of carbon filter replacement and oil exchange intervals.

Upgrading gas membranes

Biogas upgrading membranes are essential for transforming raw biogas into biomethane, but the separation efficiency of these membranes is sensitive to humidity variations. High humidity condenses water vapour on the surface of the membrane, which decreases production efficiency. If the biogas is too dry, the concentration of impurities can decrease, challenging the membranes to effectively separate them, reducing upgrading efficiency and lowering biomethane purity.

With that knowledge, maintaining dew point at or below 0 C is necessary for the most favourable operation of upgrading plants, which are more sensitive than CHP engines. Plus, the value of the gas produced is higher than that of the electricity produced, further underscoring the even more significant financial impact of lost production.

Monitoring humidity levels at each stage of the process, from heat exchangers to active carbon filtration to CHP engines and upgrading membrane units, boosts efficiency, reliability and overall sustainability in biogas production.

Harnessing accurate humidity measurements to optimize the biogas industry

As Canada’s burgeoning biogas industry expands, one thing is abundantly clear: Biogas producers nationwide must manage humidity levels across the generation process. From accurate methane volume calculations to extending the lifespan of critical components like carbon filters and gas membrane units, Vaisala’s proven humidity measurement expertise can help reduce operational costs, conserve energy and mitigate environmental impacts.

In the vast Canadian landscape, biogas represents not just an energy source but a commitment to a sustainable tomorrow for future generations. Optimizations made possible through the methane, carbon dioxide and humidity measurements Vaisala delivers don’t just improve biogas facility efficiency to help meet our energy needs responsibly – they help preserve this great country’s natural beauty and vitality.

Antti Heikkilä is a product manager at Vaisala, focusing on multigas infrared instruments and new market areas. He has over 15 years of experience in process and emission monitoring instruments and infrared gas analysis and holds a M.Sc. degree in physical chemistry. He is an active member of multiple international standardization workgroups (both ISO and CEN) on air quality and greenhouse gas measurements.

Antti Heikkilä is a product manager at Vaisala, focusing on multigas infrared instruments and new market areas. He has over 15 years of experience in process and emission monitoring instruments and infrared gas analysis and holds a M.Sc. degree in physical chemistry. He is an active member of multiple international standardization workgroups (both ISO and CEN) on air quality and greenhouse gas measurements.

This article is part of Biofuels Week 2023. To read more articles on biofuels, click here.

Print this page